A kind of preparation method of cross-linked acrylamide grafted starch

A technology of acrylamide and grafted starch, which is applied in the field of preparation of heavy metal collectors in industrial sewage treatment, can solve the problems of difficult discharging and wall sticking, and achieve the effects of easy discharging, lower viscosity and good flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

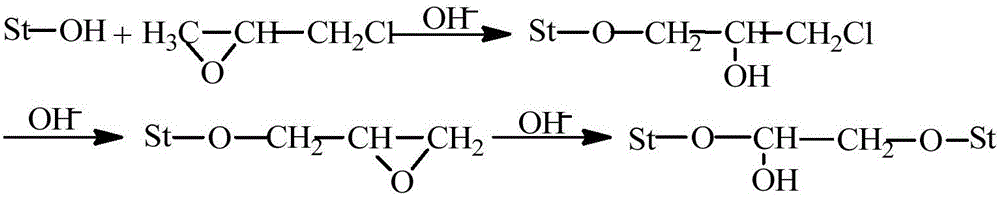

[0074] (1) Dissolve corn starch in 1% sodium chloride aqueous solution, the mass ratio of sodium chloride aqueous solution to corn starch is 1.5:1, add KOH aqueous solution with a mass fraction of 15%, and the mass ratio of KOH aqueous solution to corn starch is 1 : 75, react with epichlorohydrin in a cross-linking reactor, the cross-linking temperature is controlled at about 25°C, the reaction time is 3 hours, and the mass ratio of epichlorohydrin to corn starch is 1:50.

[0075] After the cross-linking reaction is finished, the pH value is adjusted to 6-7 with 2% hydrochloric acid, the neutralized reaction solution is filtered and washed, and the waste water is discharged to a waste water pool.

[0076] After testing, the sedimentation volume of the obtained cross-linked starch was 46mL.

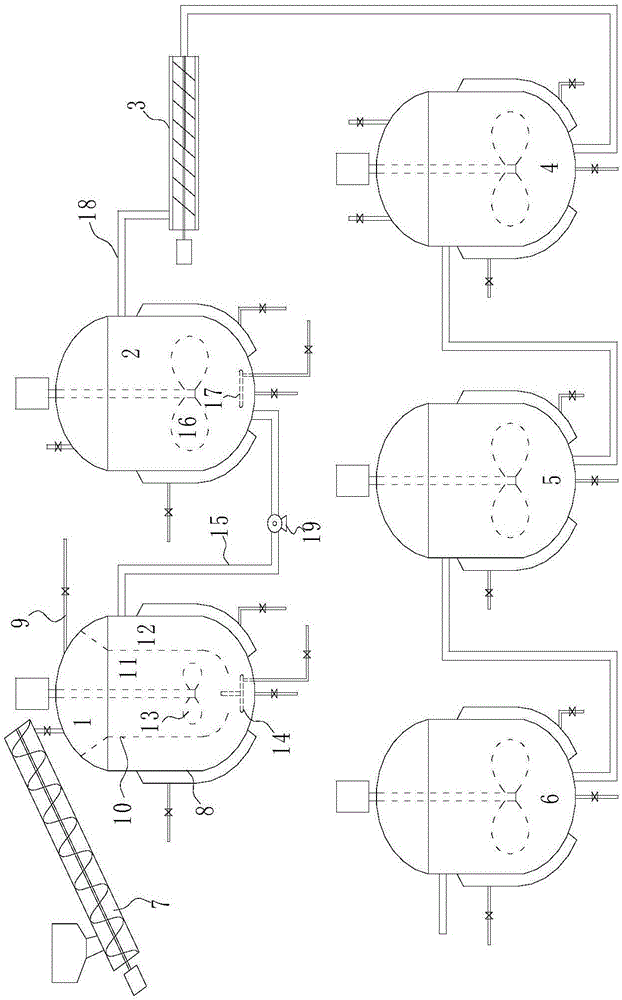

[0077] (2) The cross-linked starch pregelatinization and graft copolymerization reaction adopts continuous reaction, and the preparation device used can be found in figure 1 , including a...

Embodiment 2

[0089] (1) Dissolve corn starch in 1% sodium chloride aqueous solution, the mass ratio of sodium chloride aqueous solution to corn starch is 1.5:1, add KOH aqueous solution with a mass fraction of 15%, and the mass ratio of KOH aqueous solution to corn starch is 1 : 75, react with epichlorohydrin in a cross-linking reactor, the pH of the system is 11, the cross-linking temperature is controlled at about 25°C, the reaction time is 3 hours, and the mass ratio of epichlorohydrin to corn starch is 1 :50.

[0090] After the cross-linking reaction is finished, the pH value is adjusted to 6-7 with 2% hydrochloric acid, the neutralized reaction solution is filtered and washed, and the waste water is discharged to a waste water pool.

[0091] After testing, the sedimentation volume of the obtained cross-linked starch was 46mL.

[0092] (2) The cross-linked starch pregelatinization and graft copolymerization reaction adopts figure 1 The preparation setup shown carries out a continuous...

Embodiment 3

[0097] (1) Dissolve corn starch in 1% sodium chloride aqueous solution, the mass ratio of sodium chloride aqueous solution to corn starch is 1.5:1, add KOH aqueous solution with a mass fraction of 13%, the mass ratio of KOH aqueous solution and corn starch is 1 :75, react with epichlorohydrin in a crosslinking reactor, the pH of the system is 10, the crosslinking temperature is controlled at about 20°C, the reaction time is 6 hours, and the mass ratio of epichlorohydrin to cornstarch is 1 :50.

[0098] After the cross-linking reaction is finished, the pH value is adjusted to 6-7 with 2% hydrochloric acid, the neutralized reaction solution is filtered and washed, and the waste water is discharged to a waste water pool.

[0099] After testing, the sedimentation volume of the obtained cross-linked starch was 40 mL.

[0100] (2) The cross-linked starch pregelatinization and graft copolymerization reaction adopts figure 1 The preparation setup shown carries out a continuous react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance coefficient | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com