A kind of organometallic cobalt (ii) complex luminescent material and preparation method thereof

A technology of organic metals and luminescent materials, applied in luminescent materials, cobalt organic compounds, organic chemistry, etc., can solve the problems of poor luminous brightness, large luminous effect attenuation, and easy agglomeration of products, and achieve product phase Uniformity, easy separation and purification, high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

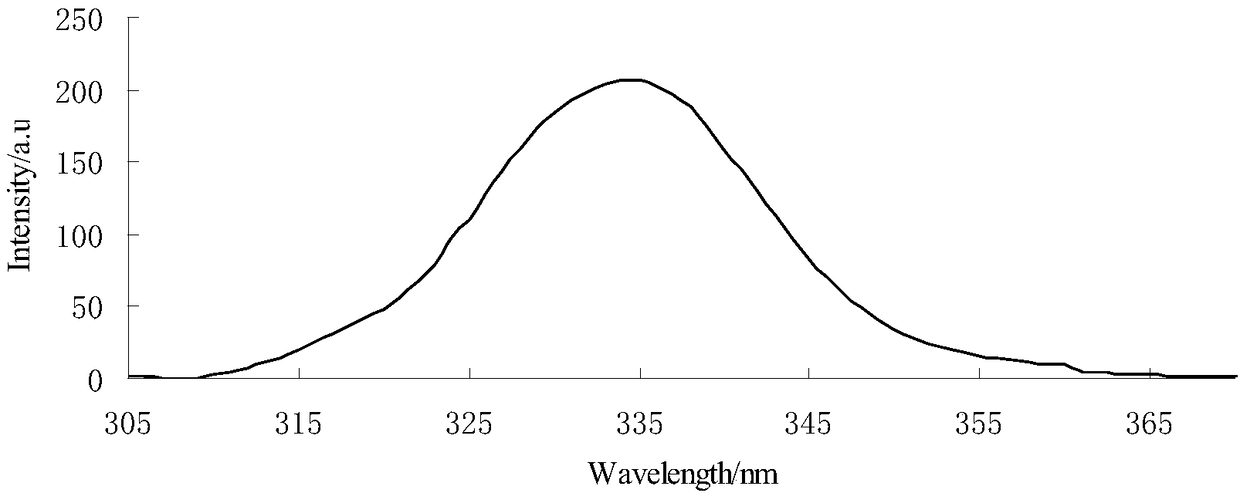

[0025] 1. Luminescent material [Co 2 (bipy) 2 (dpa) 2 (H 2 O) 5 ].4H 2 Preparation of O:

[0026] The amount ratio of the substance is: 1:1.5:1 raw material CoSO 4 .7H 2 O (1mmol), biphenyldicarboxylic acid (1.5mmol) and bipyridine (1mmol), dissolved in 40mL of ethanol aqueous solution with a volume ratio of 1:1, adjusted the pH to slightly alkaline with ethylenediamine, at 65°C After reacting for 9 hours, cool down to room temperature naturally. After filtering, put the filtrate in an open container, seal the container mouth with a microporous plastic wrap, and let the solvent evaporate slowly at room temperature. After 4 weeks, orange-red crystals are precipitated. The yield was 41.5%.

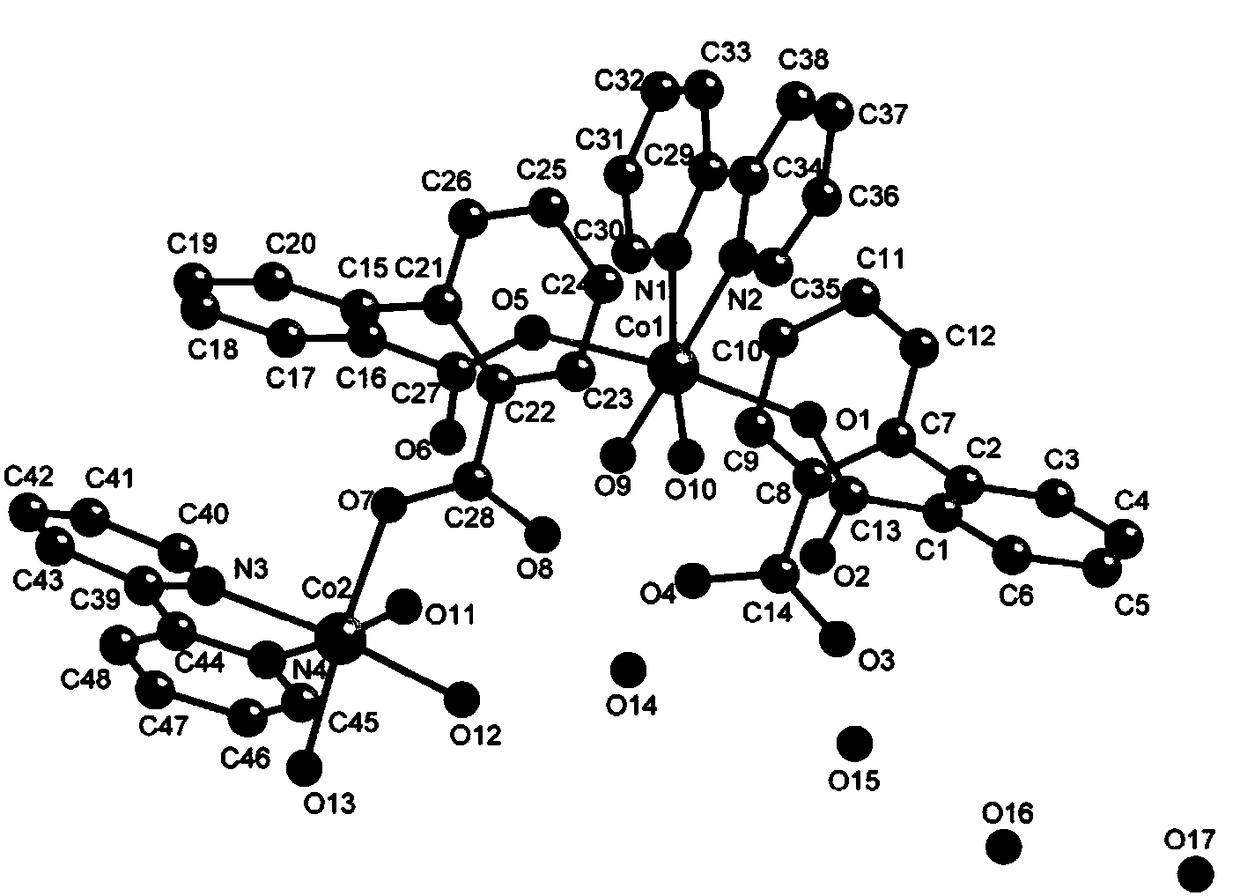

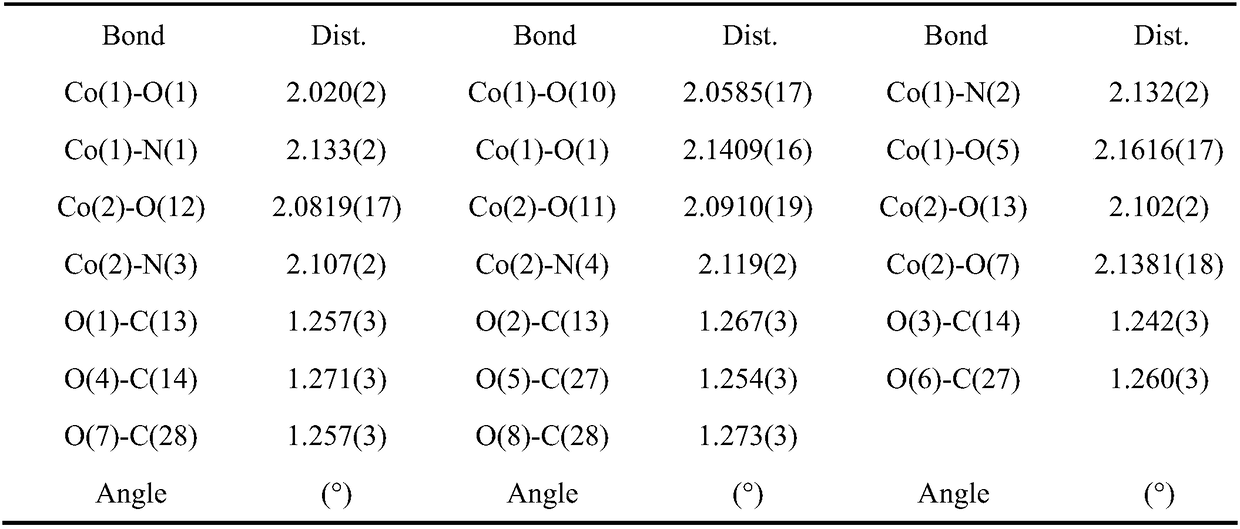

[0027] 2. For materials [Co 2 (bipy) 2 (dpa) 2 (H 2 O) 5 ].4H 2 O for crystal structure determination:

[0028] A single crystal with a material size of 0.18×0.17×0.15nm was taken, and on a Bruker SMART APEX-II CCD single crystal diffractometer, the monochromatic MoKα (λ=0.071...

Embodiment 2

[0036] The molar ratio of the substance is: 1.2:1.5:1.5 raw material CoSO 4 .7H 2 O (1.2mmol), biphenyldicarboxylic acid (1.5mmol) and bipyridine (1.5mmol), dissolved in 40mL of ethanol aqueous solution with a volume ratio of 1.2:1, adjusted the pH value slightly alkaline with ethylenediamine, at 60 After reacting at ℃ for 10 hours, cool naturally to room temperature, filter, put the filtrate in an open container, seal the container mouth with a microporous plastic wrap, let the solvent evaporate slowly at room temperature, orange-red crystals precipitate out after 4 weeks. The yield was 40.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com