Modified ammonium nitrate-fuel oil explosive

An ammonium explosive and modified technology, which is used in explosives, non-explosive/non-thermal components, offensive equipment, etc., to achieve the effect of tight coating film, improved coating ability and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

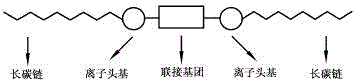

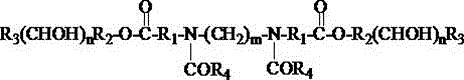

[0029]A high-performance coal mine-approved modified ammonium oil explosive, its composition and ratio are: ammonium nitrate 91.3%, high-performance composite oil phase: 3.3%, wood flour: 5.0%, high-performance ammonium nitrate modifier: 0.4 %; wherein, the high-performance composite oil phase is composed of the following components by weight percentage: composite surfactant: 1.5%, stearic acid: 15%, composite oil phase: 83.5%; wherein: composite surfactant is composed of the following components Composition by weight percentage: gemini surfactant: 70%, Pingpingjia O-10: 20%, OP-20: 10%, among them, in the general formula of bisamide diester-based nonionic gemini surfactant, m= 2, n=2, R 1 is an alkylene group with 5 carbon atoms, R 2 is an alkylene group with 1 carbon atom, R 3 is an alkyl group with 5 carbon atoms; R 4 It is an alkyl group with 1 carbon atom; wherein, the high-performance ammonium nitrate modifier is composed of the following components by weight percenta...

Embodiment 2

[0031] A high-performance rock-type modified ammonium oil explosive, its composition and ratio are: ammonium nitrate: 91.4%, high-performance composite oil phase: 3.3%, wood powder: 5%, high-performance ammonium nitrate modifier: 0.3% ; Wherein, the high-performance composite oil phase is composed of the following components by weight percentage: composite surfactant: 1.0%, stearic acid: 5%, composite oil phase: 94%; wherein: composite surfactant is composed of the following components by Composition by weight percentage: Gemini surfactant: 40%, Pingpinga O-30: 25%, Pingpinga O-5: 15%, OP-10: 20%. Among them, in the general formula of bisamide diester-based nonionic gemini surfactant, m=1, n=1, R 1 is an alkylene group with 0 carbon atoms, R 2 is an alkylene group with 5 carbon atoms, R 3 is an alkyl group with 1 carbon atom; R 4 It is an alkyl group with 5 carbon atoms; wherein, the high-performance ammonium nitrate modifier is composed of the following components by weigh...

Embodiment 3

[0033] A high-performance rock-type modified ammonium oil explosive, its composition and ratio are: ammonium nitrate: 91.7%, high-performance composite oil phase: 3.5%, wood powder: 4.5%, high-performance ammonium nitrate modifier: 0.3% ; Wherein, the high-performance composite oil phase is composed of the following components by weight percentage: composite surfactant: 2%, stearic acid: 30%, composite oil phase: 68%; wherein: composite surfactant is composed of the following components by Composition in weight percent: Gemini surfactant: 50%, Pingpinga O-20: 30%, OP-15: 20%. Among them, in the general formula of bisamide diester-based nonionic gemini surfactant, m=2, n=2, R 1 is an alkylene group with 3 carbon atoms, R 2 is an alkylene group with 3 carbon atoms, R 3 is an alkyl group with 3 carbon atoms; R 4 It is an alkyl group with 3 carbon atoms; wherein, the high-performance ammonium nitrate modifier is composed of the following components by weight percentage: gemini ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com