A method for cultivating fluoride-tolerant anaerobic ammonium oxidation granular sludge

A technology of anaerobic ammonium oxidation and granular sludge, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems affecting biological activity and process performance, and increase load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The composition of the simulated wastewater is: ammonia nitrogen 140-280mg L -1 , Nitrite nitrogen 140~280mg·L -1 , KH 2 PO 4 10mg·L -1 , CaCl 2 2H 2 O 5.6mg·L -1 , MgSO 4 ·7H 2 O 300mg·L -1 , KHCO 3 1250mg·L -1 , the concentrations of trace elements Ⅰ and Ⅱ are respectively:

[0021] Trace elements Ⅰ (g L -1 ): EDTA 5, FeSO 4 ·7H 2 O 9.14.

[0022] Trace element Ⅱ (g L -1 ): EDTA 15, ZnSO 4 ·7H 2 O 0.43, CoCl 2·6H 2 O 0.24, MnCl 2 4H 2 O0.99, CuSO 4 ·5H 2 O 0.25, NaMoO 4 2H 2 O 0.22, NiCl 2 ·6H 2 O0.21, H 3 BO 4 0.014.

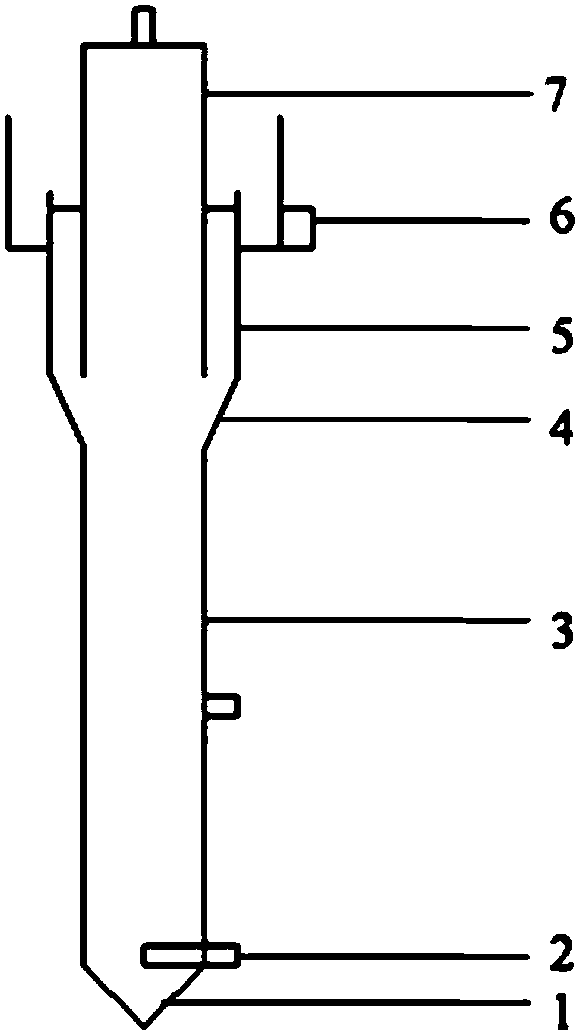

[0023] In continuous flow, an upflow anaerobic sludge bed reactor with an effective volume of 1 L (such as figure 1 ), with an activity of 0.211g TN·g -1 VSS·d -1 The anammox granular sludge was used as the inoculation source. The sludge concentration in the reactor after inoculation is 15-20g·L -1 . The operating conditions of the reactor are anaerobic, light-proof, temperature of 35±1°C, influent pH of 7.91±0.21, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com