Integrated grinding and polishing dust catcher

An all-in-one, dust collector technology, used in grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc., can solve the problems of difficult dust collection, little effect, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

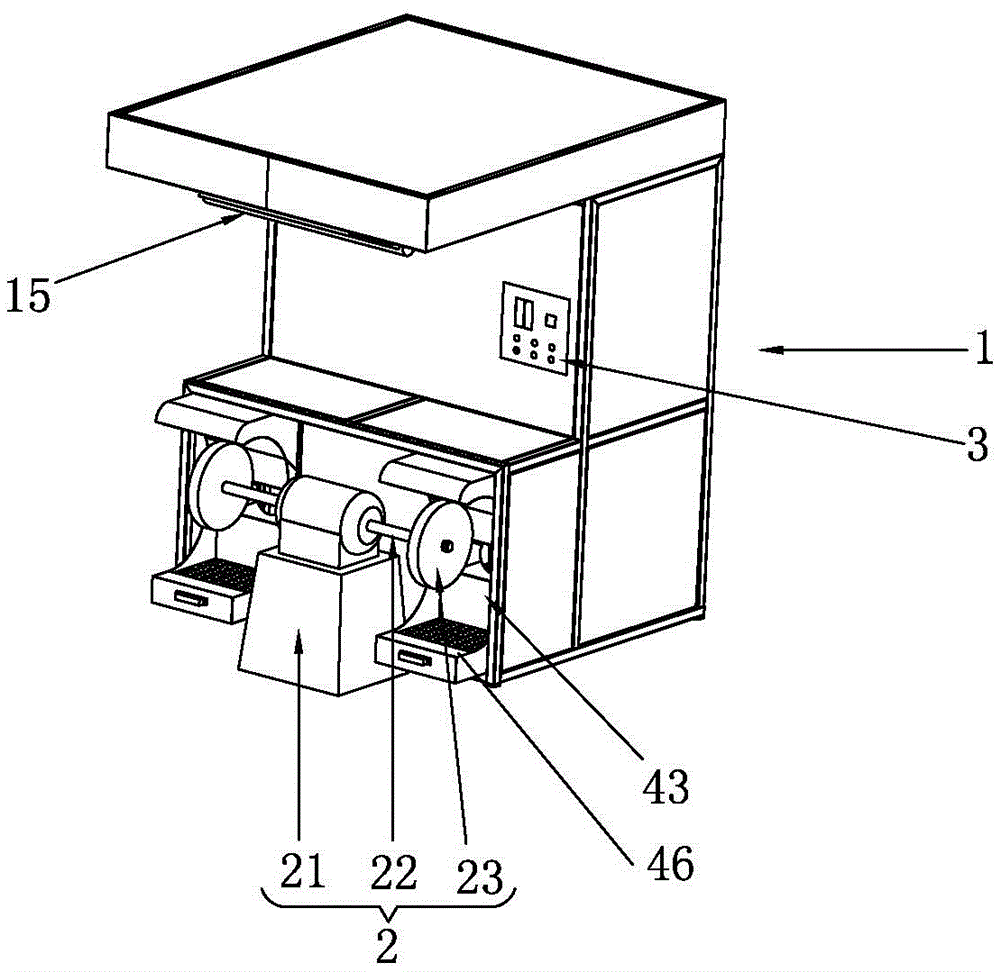

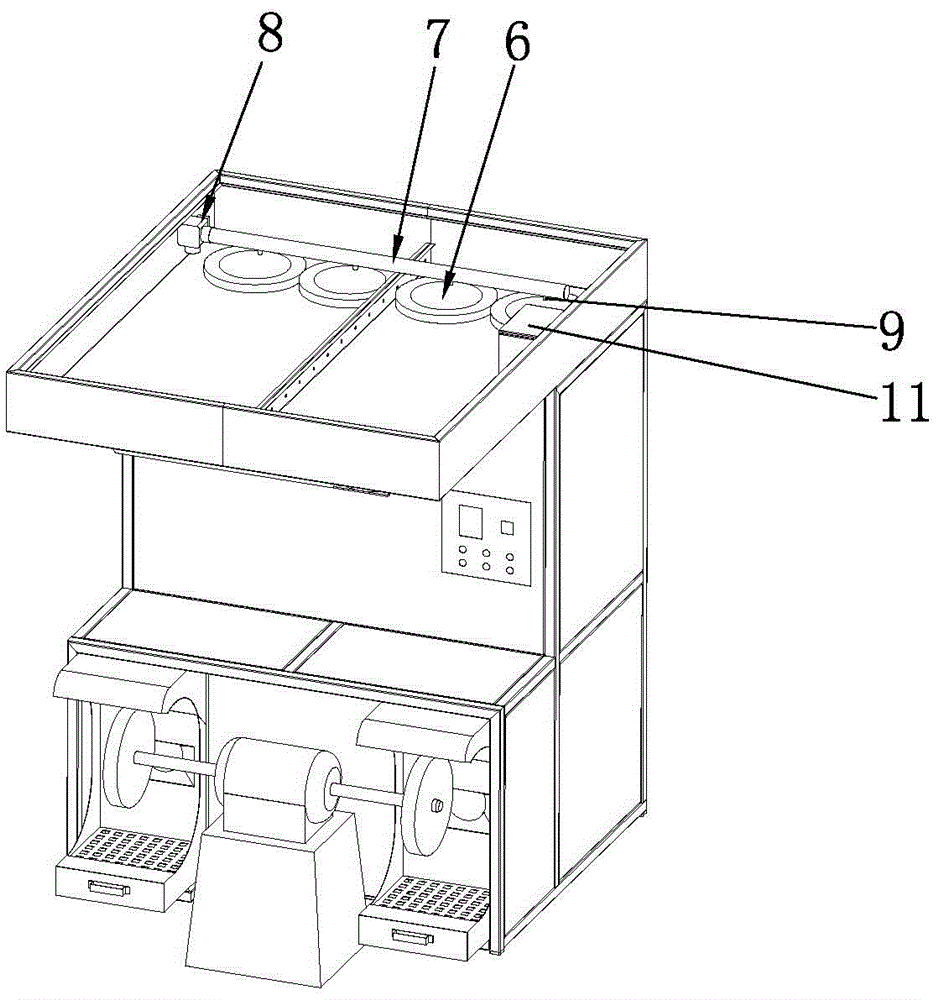

[0036] The integrated grinding and polishing dust remover provided by the present invention includes a box-type frame 1, a grinding and polishing machine 2 and a control electric box 3. Paint spraying treatment is carried out, the top plate is a filter plate, and the filtered clean gas is directly discharged from the top plate; the surrounding plate is made of A3 cold plate laser cutting and bending, and is assembled by screw fastening to form a frame structure, which is beautiful Generous, small footprint. The lower end of the box-type frame 1 is provided with a dust suction device 4 insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com