Liquid cooling heat sink

A heat sink and liquid cooling technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of small space, unfavorable convective heat transfer, the heat sink should not be too large, and the heat transfer effect is reduced, so as to achieve simple structure and small volume , the effect of large heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

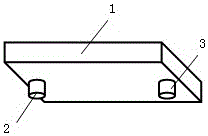

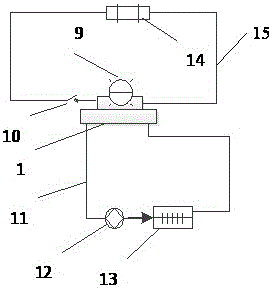

[0022] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will be combined with the attached image 3 , using a liquid cooling radiator of the present invention for high-power electronic components (such as high-power LEDs) will further describe the present invention in detail.

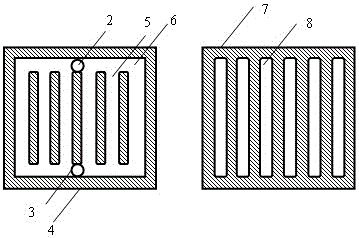

[0023] First, process the liquid-cooled radiator (1): Take two copper blocks of 100mm×100mm and thickness of 19mm as the processing objects, and process the liquid-cooled radiator according to the following steps: select two pieces with good thermal conductivity and have a certain thickness The metal plates a (4) and b (7); process the metal plate a (4) at a certain distance along the boundary to form a groove space (6) that communicates with each other and has multiple parallel passages (5) in the middle; (7) Process some parallel grooves, the positions of these parallel grooves (8) correspond to the parallel channels (5) processed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com