Device and method for testing arsenic through atomic fluorescence method

An atomic fluorescence and reactor technology, applied in the field of chemical analysis, can solve the problem of difficult control of capture and release of arsenic elements, and achieve the effects of difficult control of capture and release of arsenic elements, stable analysis, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

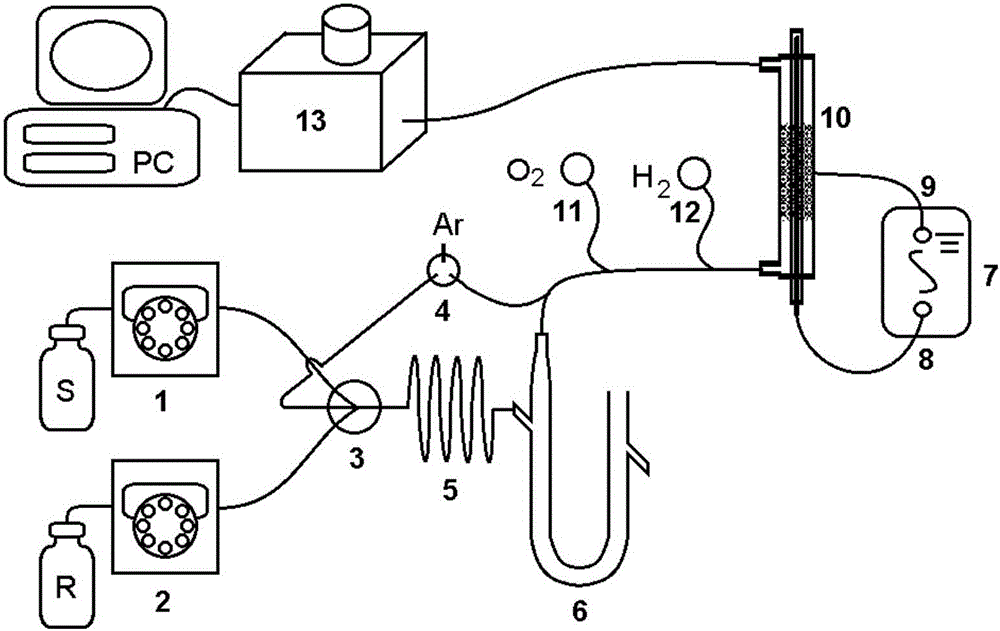

[0020] When the standard solution containing arsenic is passed into the sample peristaltic pump 1, it is mixed with the potassium borohydride solution in the reaction reagent peristaltic pump 2 in the four-way mixer 3, and the 600mL / min argon gas introduced by the three-way connection of the argon source 4 is brought in The reaction ring 5 produces arsenic hydride, and enters the gas-liquid separator 6 to complete the gas-liquid separation. Under the condition that 40 mL / min oxygen is fed into the oxygen source 11 and the voltage of the power supply 7 is set at 9.2 kV, the dielectric barrier discharge reactor 10 The capture of arsenic is completed; then the argon source 4 is connected to the argon gas to purge for 180s, and then the hydrogen gas source 12 is supplied with 200mL / min hydrogen gas. At this time, the voltage of the power supply 7 is 9.5kV, and the release of arsenic is completed; The gas enters the atomic fluorescence spectrometer 13 along with the carrier gas. Un...

Embodiment 2

[0022] Taking the arsenic-containing water sample (national standard GBW08605) as an example, the dielectric barrier discharge pre-concentration device of the present invention is connected in series with the atomic fluorescence spectrometer, and other conditions are the same as in the first embodiment. The content of arsenic in the measured sample was 499±4 micrograms / liter, the average value was within the standard value of 500±8 micrograms / liter of the standard substance, and the relative standard deviation of three determinations was 0.8%.

Embodiment 3

[0024] Taking the arsenic-containing water sample (standard substance GSB-Z50004-200431) as an example, the dielectric barrier discharge pre-enrichment device of the present invention is connected in series with the atomic fluorescence spectrometer, and other conditions are the same as in the first embodiment. The content of arsenic in the measured sample was 58.5±0.4 micrograms / liter, the average value was within the standard value of 60.6±4.2 micrograms / liter of the standard substance, and the relative standard deviation of three determinations was 0.7%.

[0025] The above three examples illustrate that the present invention provides an enrichment device for measuring arsenic by atomic fluorescence method and its use method, which can effectively enrich trace arsenic in water samples and ensure the accuracy and stability of the determination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com