A Fatigue Test Device for Anti-Icing Main Blade

A technology for fatigue testing and main blades, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc. It can solve problems such as flapping moment, shimmy bending moment and torque difficulties, and achieve compact structure, The effect of high loading accuracy and fast frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

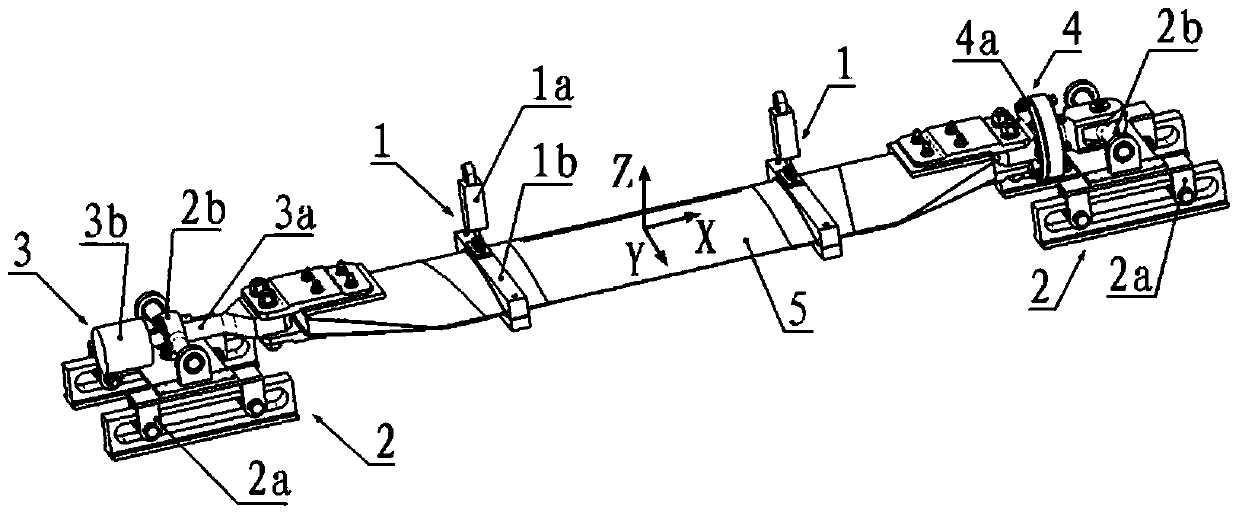

[0030] like figure 1 As shown, in this embodiment, the two ends of the test piece 5 are connected to the support platform 2 by two different devices. In the illustration, the test piece 5 is the main blade, with its center as the origin, The long side is taken as the X axis, the upward direction is the Z axis, and the direction perpendicular to the X and Z axes is the Y axis. It is a schematic illustration of the anti-icing main blade fatigue test device.

[0031] refer to figure 1 , the two bending moment application assemblies 1 are symmetrically distributed left and right in the X-axis direction, and are respectively arranged on the test piece 5 from the center to the two ends, and the two bending moment application assemblies 1 are connected to the test piece 5 The center is the same distance. Each bending moment application assembly 1 includes a set of linear actuator 1a and clamping mechanism 1b. The connection between the linear actuator 1a and the clamping mechanism ...

Embodiment 2

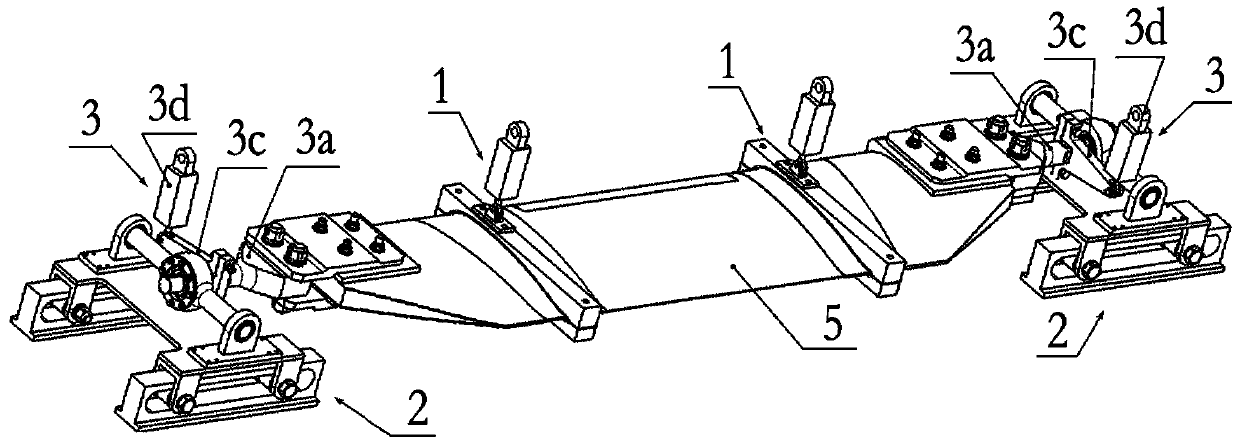

[0039] Similar to Example 1, the difference is that when the stiffness of the test piece 5 is not large enough, and the torque cannot be smoothly transmitted from one end of the test piece 5 to the other end under the condition of bending deformation, two support platforms 2 can be selected A test program in which the torque application assembly 3 is installed. That is, in this embodiment, if figure 2 As shown, the connecting component is a torque applying component 3, that is, both ends of the test piece 5 are connected to the support platform 2 through the torque applying component 3. This solution adjusts the flapping moment and shimmy bending moment by controlling the installation angle of the rotating shaft 3a The proportional relationship, loading control is more difficult.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com