High-speed testing machine for joint bearings with single swing follower and double disc cam

A technology of joint bearings and disc cams, applied in the direction of mechanical bearing testing, etc., can solve the problems that restrict the development of high-frequency swing aviation joint bearings, cannot meet the fatigue test of high-frequency swing aviation joint bearings, and the dynamic balance of difficult-to-move components, etc., to achieve The effect of light wear, small friction and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

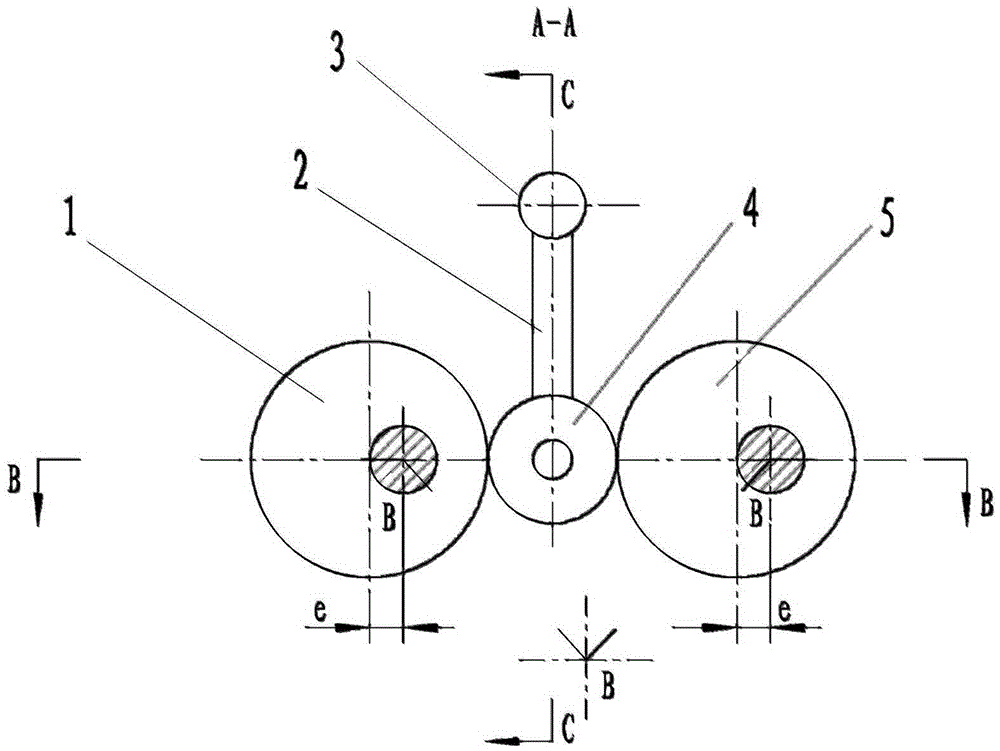

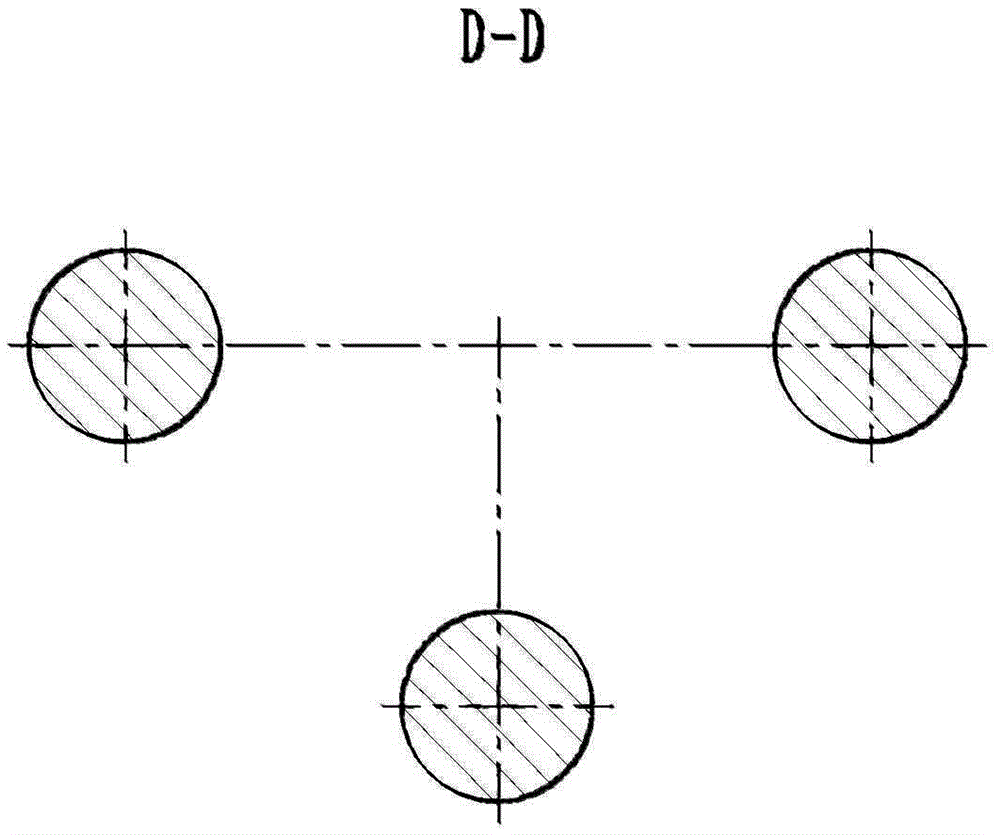

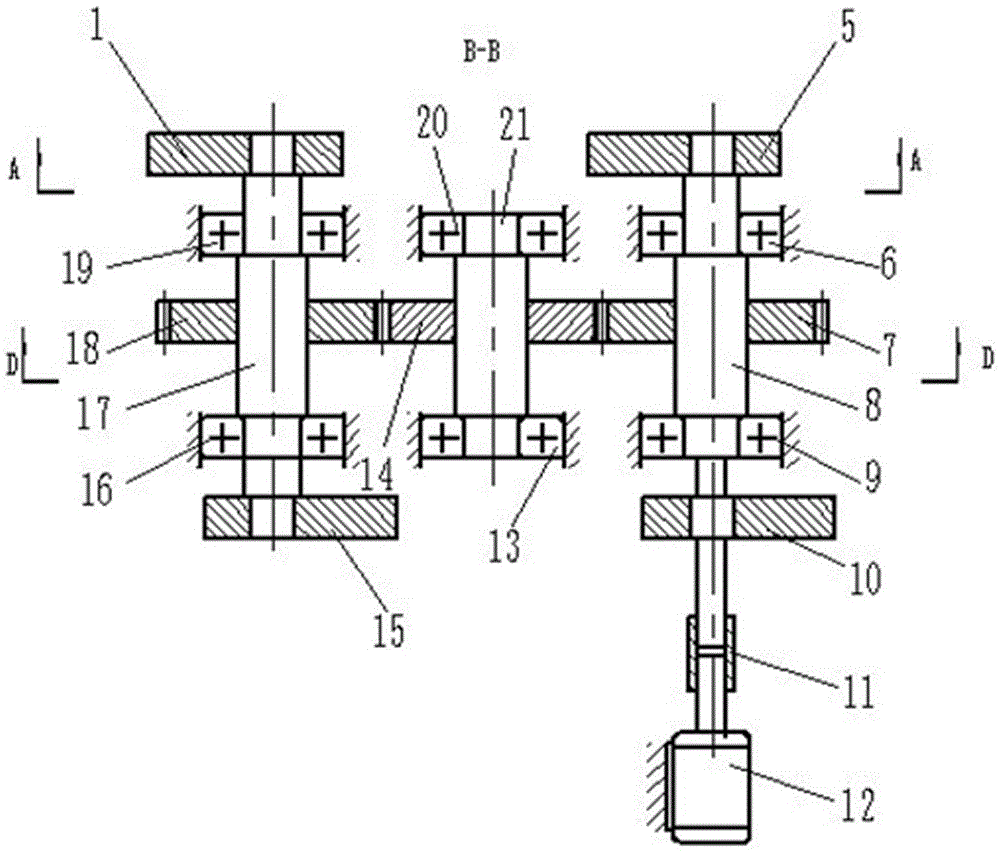

[0019] exist Figure 1 to Figure 4 In the schematic diagram of the working state of a single-oscillating follower double-disc cam joint bearing high-speed testing machine shown, one end of a high-speed rotating shaft 8 supported on two rolling bearings I and II (6, 9) passes through the coupling The device 11 is connected with the motor (or hydraulic motor) 12, a transmission gear I7 is fixedly connected in the middle of the high-speed rotating shaft 8, and one end of the high-speed rotating shaft 8 is connected with a balance cam I10 and the other end is connected with a working cam I5. The middle part of a high-speed rotating shaft II17 supported on two rolling bearings III and IV (16, 19) is fixedly connected with a transmission gear II18, and one end of the high-speed rotating shaft II17 is fixedly connected with a balance cam II15 and the other end is fixedly connected with a working cam II1 . The middle part of an intermediate transmission shaft 21 supported on two roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com