Mechanical analysis method for high-temperature fatigue of high-temperature alloy baffles

An analytical method and technology for superalloys, which are applied in the direction of analyzing materials, scientific instruments, and testing the strength of materials by applying repetitive force/pulsation force, to achieve the effect of ensuring verticality and parallelism, ensuring dimensional accuracy, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

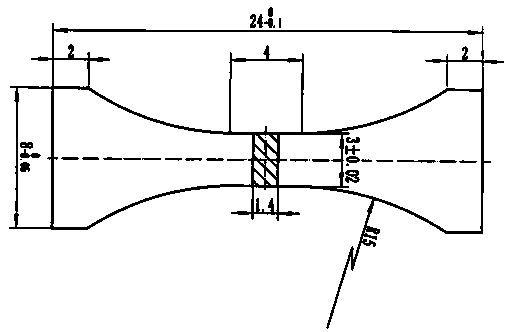

[0031] 1. Small sample design and sampling of turbine disk baffle

[0032] The small specimen design of the front and rear baffles mainly considers two factors: specimen size and auxiliary fixtures.

[0033] 2.1. Sample size

[0034] According to GB / T 3075-2008 Metal Material Fatigue Test Axial Force Control Method, the cross-sectional size of the sample should be such that the maximum load expressed in absolute value is not less than 25% of the load of the testing machine. The mechanical properties of the front baffle and rear baffle were tested using a 505C / 02 hydraulic low cycle fatigue testing machine. The maximum load of the 505C / 02 hydraulic low cycle fatigue testing machine is 10kN. In order to meet the condition that the maximum load of the test is not less than 25% of the load of the testing mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com