High-speed testing machine for offset double oscillating follower double swash plate end face cam joint bearing

An end cam and spherical plain bearing technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of inability to meet the fatigue test of high-frequency swinging aeronautical spherical plain bearings, restricting the development of high-frequency swinging aeronautical spherical plain bearings, and dynamic balance of difficult-to-move components, so as to achieve wear and tear. Light, low friction, low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

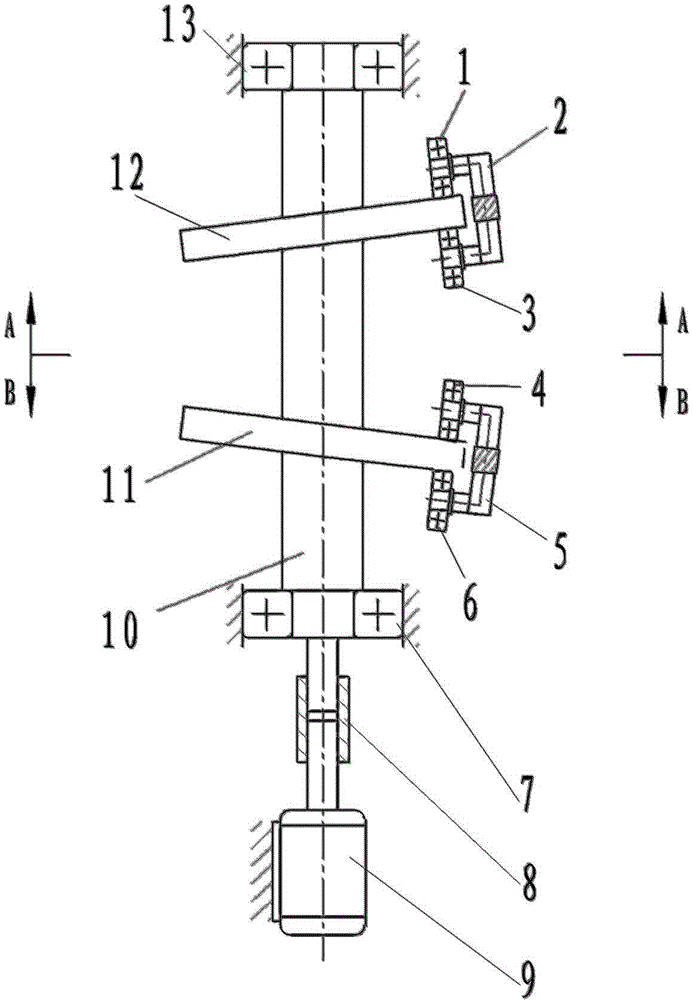

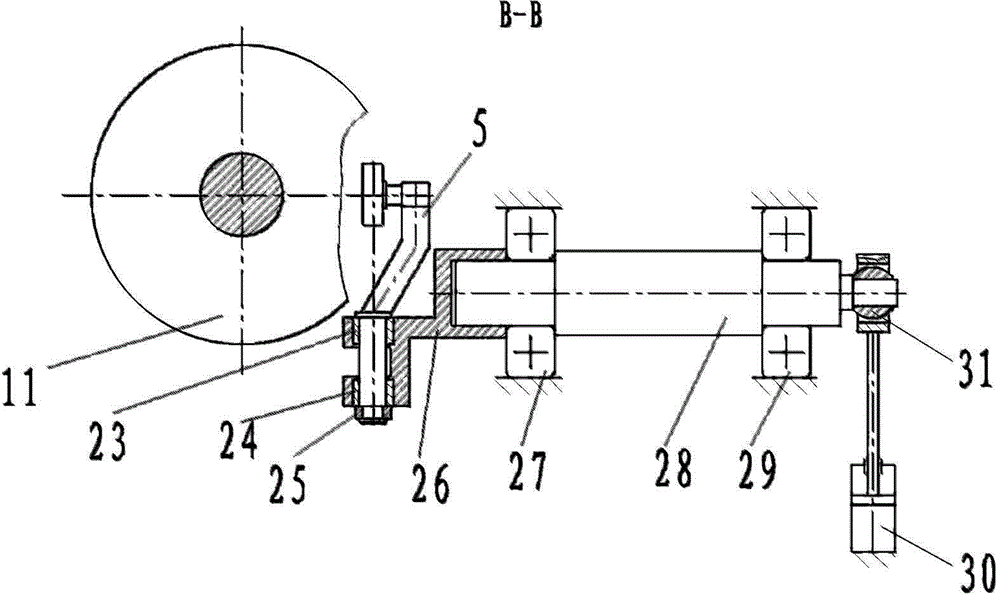

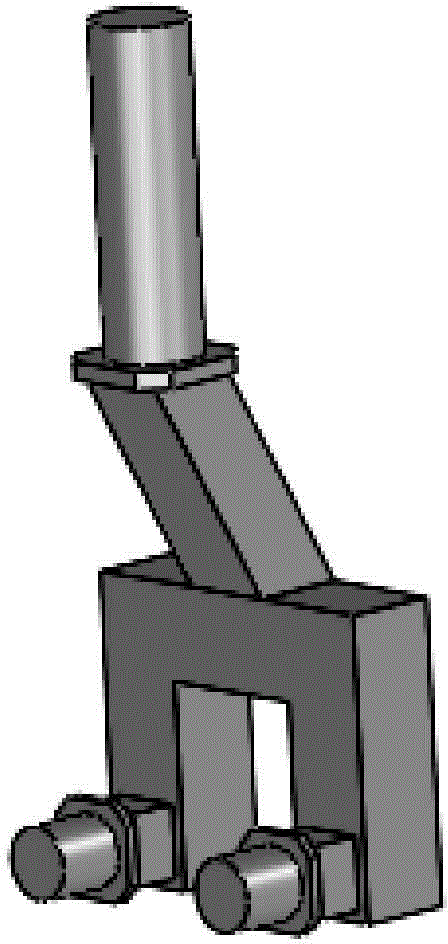

[0018] exist Figure 1 ~ Figure 3 Shown is a schematic diagram of the working state of a high-speed testing machine for offset double sway followers double swash plate end face cam joint bearings. One end of the high-speed rotating shaft 10 supported on two rolling bearings V and VI (7, 13) passes through The shaft device 8 is connected with the motor 9 (or hydraulic motor), and two swash plate end cams I, II (11, 12) are fixedly connected to the high-speed rotating shaft 10, and the two swash plate end cams I, II (11, 12 ) is symmetrical with respect to the plane that passes through the middle plane of each swash plate end face cam and the line connecting the two intersection points of the high-speed rotating shaft 10 axis and is perpendicular to the high-speed rotating shaft 10 axis, and each swash plate end face cam I, II (11, 12 ) The angle between the normal of the middle plane and the axis of the high-speed rotating shaft 10 is 15°. The high-frequency swing shaft I17 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com