Method for detecting dielectric liquid level in closed porcelain cover through ultrasonic non-interventive method

A dielectric liquid, non-intervention technology, applied in the direction of liquid/fluid solid measurement, measuring device, liquid level indicator, etc., can solve the problems of unstable signal, change of electric field distribution, easy misjudgment, etc., and achieve simple and convenient operation , high detection sensitivity, no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, a 110KV ceramic sleeve oil-filled outdoor terminal is taken as an example. The sound velocity of the wall material is 6850m / s. The ultrasonic non-interventional method for detecting the oil level in the sealed porcelain sleeve consists of the following steps:

[0025] (1) Adjust the baseline ratio and scanning range when the digital flaw detector is horizontal, so that the baseline display range is at least the maximum thickness of the porcelain casing, and adjust the working frequency of the flaw detector to 5MHz.

[0026] In this embodiment, the Hanwei HS620 digital ultrasonic flaw detector produced by Wuhan Zhongke is used, the operating frequency (0.5-20MHz), the sound velocity range (100-20000) m / s, the pulse intensity 600V; the attenuator accuracy <+1dB / 12dDB; The maximum gain is 110dB. The probe in this embodiment is a 7.5 MHz Φ10 longitudinal wave straight probe, and the chip length is 6 mm.

[0027] (2) Divide the control sleeve that has no...

Embodiment 2

[0031] The probe of this embodiment is a straight longitudinal wave probe of 1.25MHzΦ10, the chip length is 4mm, and the wall material with a sound velocity of 5960m / s is selected for use.

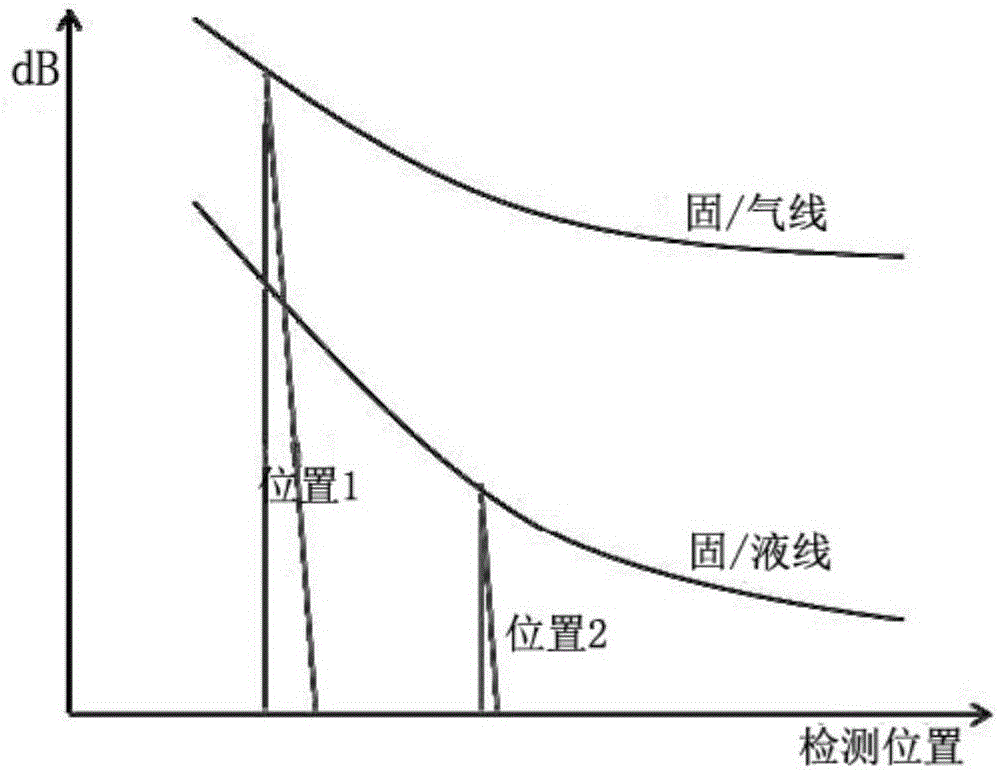

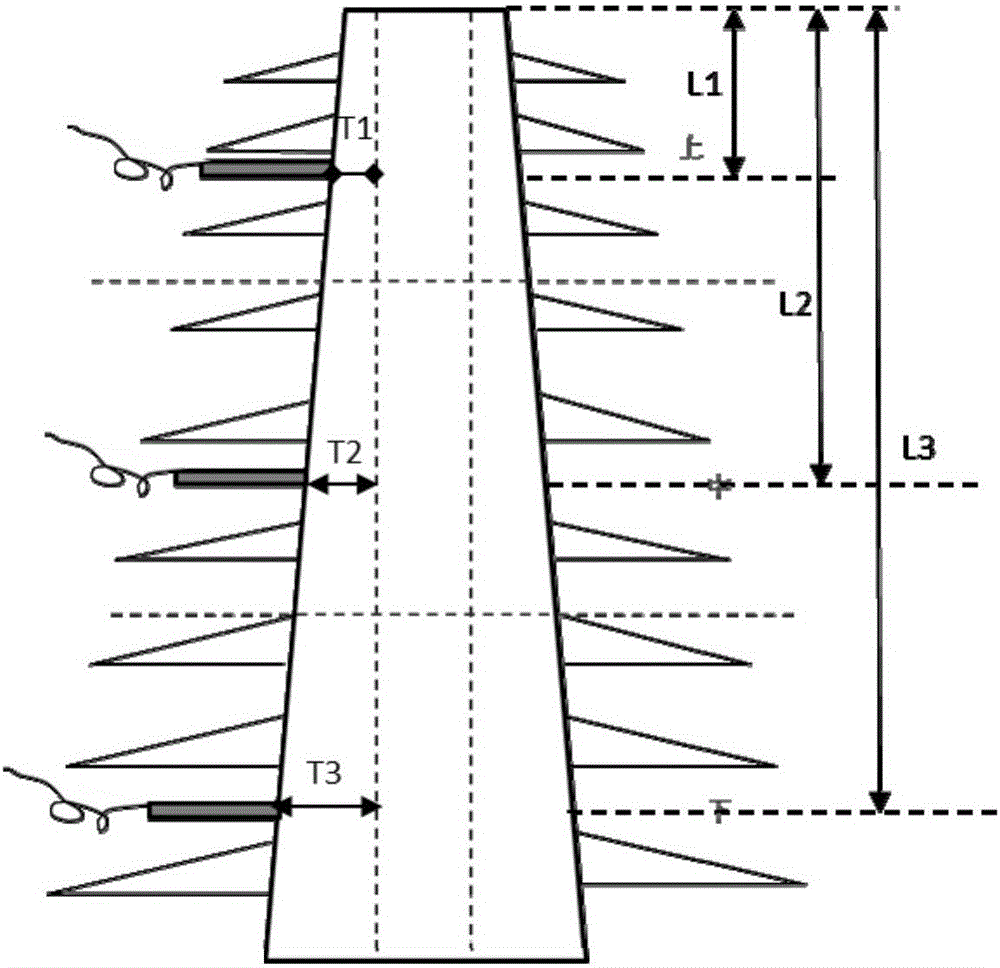

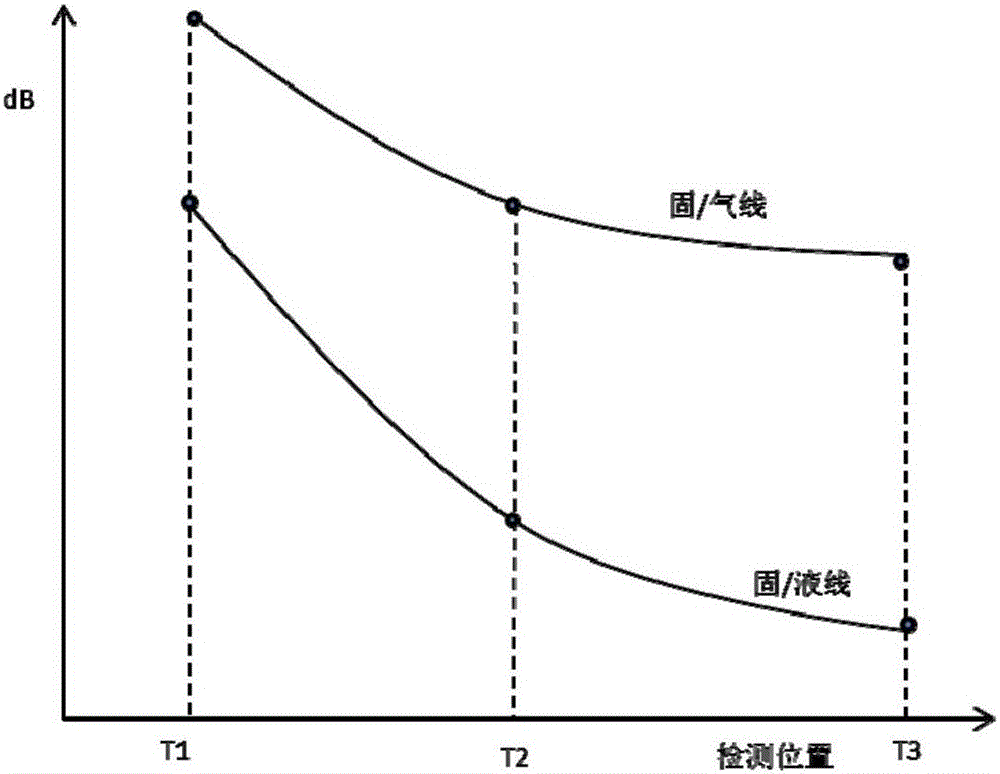

[0032] In order to ensure that the fitted control curve is more accurate, in step (2) of this embodiment, the control porcelain sleeve that has not been injected with a dielectric liquid medium is divided into the upper section, the middle section and the lower section, and 2 points are respectively taken on each section as At the detection point, apply a small amount of couplant to couple the probe to the recessed side wall between two adjacent sheds outside the porcelain sleeve; first couple the probe to the detection point 1 of the upper section, and the probe is directed into the wall of the porcelain sleeve Ultrasonic waves are emitted, and the sound waves propagating in the wall of the porcelain sleeve are reflected at the solid / gas interface. The reflected echoes are received by the ...

Embodiment 3

[0036] The probe of this embodiment selects the longitudinal wave small-angle probe of 10MHzΦ10, its angle is 8 degrees, the chip length is 8mm, and selects the wall material sound velocity to be the ceramic cover of 7530m / s, and its size is identical with embodiment 1.

[0037] Other steps are identical with embodiment 1 or 2.

[0038] In the actual detection process, due to the aging of the dielectric liquid in the porcelain sleeve to be tested, the peak of the first interface echo obtained at the point to be tested may fall on the solid / air interface distance-amplitude curve or the solid / liquid interface distance- The position adjacent to the bottom of the amplitude curve is a reasonable error and does not affect the judgment of the test result.

[0039] The ceramic bushing of the present invention can be selected from the standard porcelain bushing whose sound velocity ranges from 5000 to 8000m / s. Well, the frequency and chip size of the detection probe can also be adapti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com