Water cooling plate

A water-cooled plate and partition technology, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problems of low cooling efficiency, high cost, complex processing technology of high-efficiency coolers, etc., and achieve simple structure, Easy to process and produce, get rid of inefficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

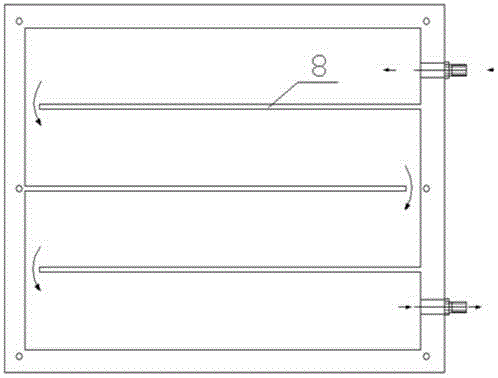

[0034] Figure 5 A schematic diagram of the baffled coolant flow inside the double-inlet and double-outlet joint water-cooling plate is given. Through the arrangement of the partition plate 8, two liquid cooling medium flow channels are formed inside the water-cooling plate, with two pairs of inlets and outlets, which are welded at the inlet and outlet respectively. Import and export conical outer wire connector 3.

[0035] Through the arrangement of the partitions 8, a plurality of liquid cooling medium flow channels can be formed, and the inlet and outlet conical outer thread joints 3 can be welded at the corresponding inlets and outlets.

[0036] Figure 6 A schematic diagram of the internal flow channels and heat dissipation fins of the water-cooled plate is given. Regardless of the form of the liquid cooling medium flow channel, the arrangement of the cooling fins 2 in the liquid cooling medium flow channel is basically the same.

[0037] The heat dissipation fins 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com