Medical waste incineration system

A technology of medical waste and storage area, which is applied in the field of medical waste treatment system, can solve the problems that medical waste cannot be incinerated in time, the bag is easy to burn, and cross-contamination, so as to achieve the effect of eliminating cross-contamination and saving the use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

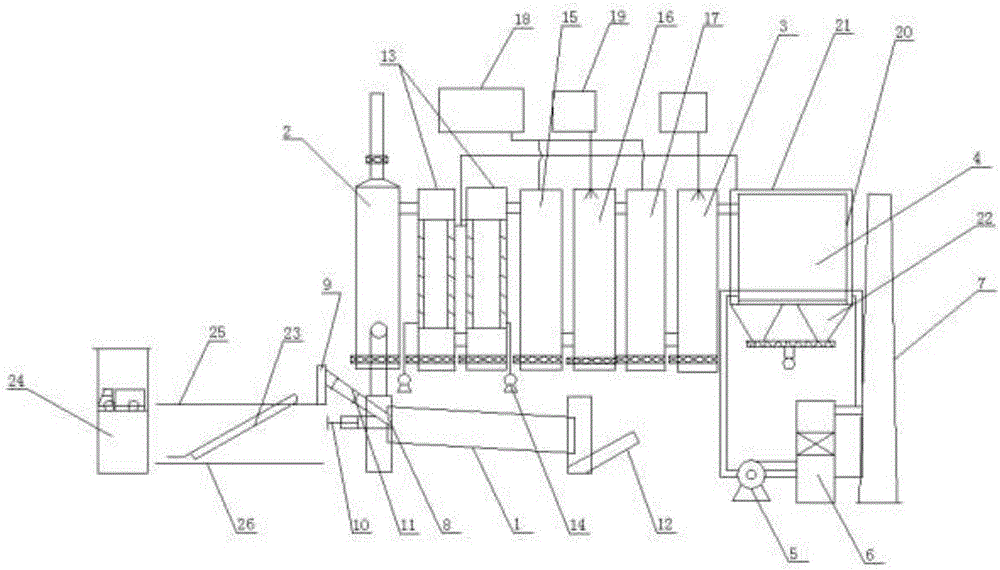

[0020] Such as figure 1 As shown, the medical waste incineration system includes a feeding device, a rotary kiln 1, a second combustion chamber 2, a heat exchange device, a quenching device, an adsorption tower 3, a bag filter 4, an induced draft fan 5, a washing tower 6, and a chimney connected in sequence 7; The feeding device includes a waste barrel storage area 25, a clean barrel storage area 26, and a lifting and unloading platform 24 for lifting vehicles to the waste barrel storage area 25; between the medical waste barrel storage area 25 and the clean barrel storage area 26 An automatic revolving barrel cleaning machine is connected; the bag dust collector 4 has an outlet, and the outlet is connected with a mixer 22 for turning the ashes of the burned medical waste into a solid; in order to save space, the medical waste barrel storage area 25 in this embodiment is clean The barrel storage area 26 is set up and down; the present invention places the clean revolving barrel...

Embodiment 2

[0025] The difference between this embodiment and embodiment 1 is that the rotary kiln 1 is provided with a push cylinder 10 for pushing the medical waste in the feed port into the rotary kiln 1; the feed channel 8 is provided with a double gate 11; medical waste Through the double gate 11, the pushing cylinder 10 pushes the medical waste at the feed port into the rotary kiln 1, avoiding the feed blockage of the rotary kiln 1.

Embodiment 3

[0027] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the baghouse 4 includes a baghouse 20 and a housing 21; the baghouse 20 is arranged in the housing 21, and there is a gap between the baghouse 20 and the housing 21. At least one heat exchanger 13 is connected through a pipe; the thermal energy air converted by the heat exchanger 13 is introduced into the gap to keep the bag warehouse 20 stable and avoid condensation on the inner or outer wall of the bag warehouse 20, while increasing The filter area of the bag warehouse 20 reduces its load and can work stably and continuously during dust cleaning.

[0028] Example 1-3 When in use, the lifting unloading table 24 lifts the vehicle containing medical waste to the waste barrel storage area 25, and the elevator 9 lifts out multiple revolving barrels containing medical waste to pour the medical waste into it. The feed channel 8, under the action of the double gate 11 and the push cylinder 10, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com