Steel structure and high-strength bolt friction type connecting method based on particle anti-sliding effect

A technology of high-strength bolts and connection methods, which is applied in building structures, buildings, etc., can solve the problems of long cycle, complex process, and reduce the anti-slip coefficient of contact surfaces, and achieve the effect of convenient production, simplified process and shortened production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

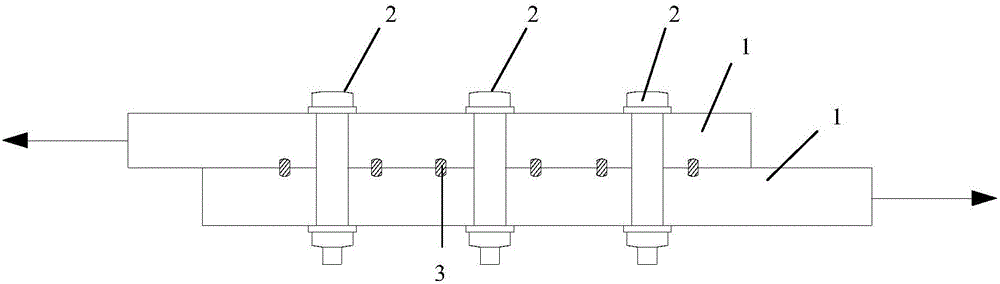

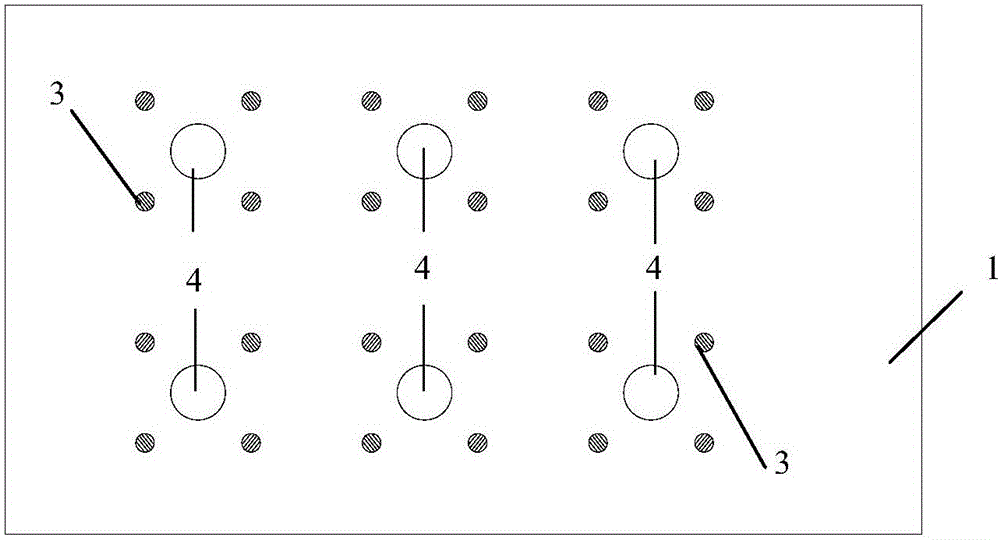

[0024] Such as Figure 1-4 Shown: A high-strength bolt friction connection of steel structure based on particle anti-slip effect, including steel connecting plate 1, high-strength bolt 2, pressed particles 3, and bolt hole 4.

[0025] figure 1 It is a structural schematic diagram of a high-strength bolt friction connection of steel structure based on the particle anti-slip effect of the present invention. The material of the pressed particles 3 is made of alloy steel, and the Rockwell hardness of the pressed particles reaches 3 times that of the Rockwell hardness of the steel connecting plate. times, the strength is not less than 1.5 times that of the steel connecting plate, and the surface of the pressed particles 3 has undergone anti-corrosion treatment; the two steel connecting plates 1 are connected together by high-strength bolts 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com