Method for improving viscose bamboo pulp reaction performance

A technology of reactivity and bamboo pulp is applied in the field of improving the reactivity of bamboo pulp, which can solve the problems of increasing the pore structure of pulp and the like, and achieve the effects of improving reactivity, good selectivity and increasing adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

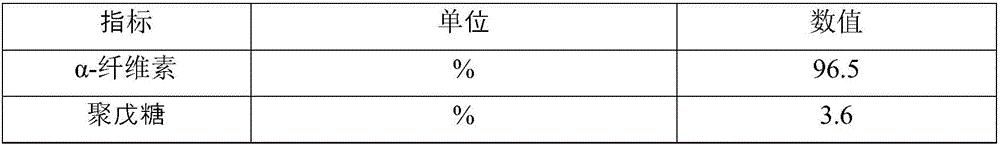

Embodiment 1

[0022] (1) Pulp board pretreatment: shred 360g Cizhu dry pulp board into pulp pieces, soak them in 5L deionized water for 4 hours, transfer them all to the Wally beater without lever arm load, and continue to add deionized water When the total volume is 23L, dissociate the fibers for 30 minutes;

[0023] (2) Pretreatment before auxiliary agent treatment: Wally beater plus (54±1)N lever arm load, for the slurry obtained after the treatment in step (1), under the line speed of the knife roller at 32m / s, Carry out the beating operation for 4 minutes. After the beating operation is completed, put the slurry into a 400-mesh mesh bag to remove moisture until the slurry concentration is 10%, so as to obtain a slurry suspension.

[0024] (3) Auxiliary treatment: transfer the slurry suspension obtained after the treatment in step (2) into a polyvinyl chloride sealed bag, and place the sealed bag in a constant temperature water bath, and adjust the temperature to 40°C. Add the auxiliar...

Embodiment 2

[0030] The operation method of embodiment two is:

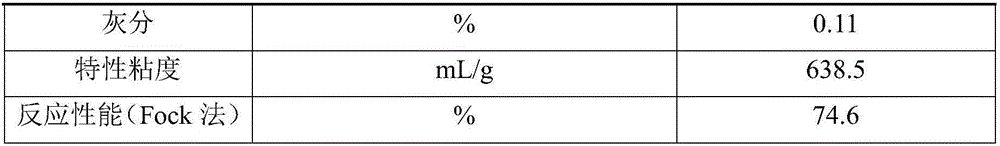

[0031] On the basis of the process of Example 1, step (2) is not added and no auxiliary agent is added in step (3), all the other are consistent with the completion steps of Example 1, the α-cellulose obtained is 95.8%, and the polypentose is 4.1%, ash content 0.17%, intrinsic viscosity 640.3mL / g, reactivity (Fock) 60.6%.

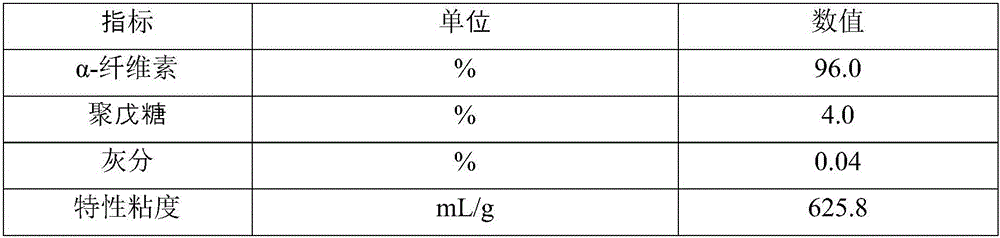

Embodiment 3

[0033] (1) Pulp board pretreatment: shred 360g hemp bamboo dry pulp board into pulp pieces, soak them in 5L deionized water for 4 hours, transfer them all to the Wally beater without lever arm load, and continue to add deionized water When the total volume is 23L, carry out fiber dissociation treatment, and the dissolving time is 35min;

[0034] (2) Pretreatment before auxiliary agent treatment: Wally beater plus (54±1)N lever arm load, for the slurry obtained after the treatment in step (1), under the linear speed of the knife roller at 33m / s, Carry out the beating operation for 5 minutes. After the beating operation is completed, put the slurry into a 400-mesh mesh bag to remove moisture until the slurry concentration is 8%, to obtain a slurry suspension.

[0035] (3) Auxiliary treatment: transfer the slurry suspension obtained after the treatment in step (2) into a polyvinyl chloride sealed bag, place the sealed bag in a constant temperature water bath, adjust the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com