Modifying method of super-hydrophobic performance of indoor power transformation equipment

A substation equipment, super-hydrophobic technology, applied in biocide-containing paints, antifouling/underwater coatings, coatings, etc., to reduce costs, improve work efficiency, and improve working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

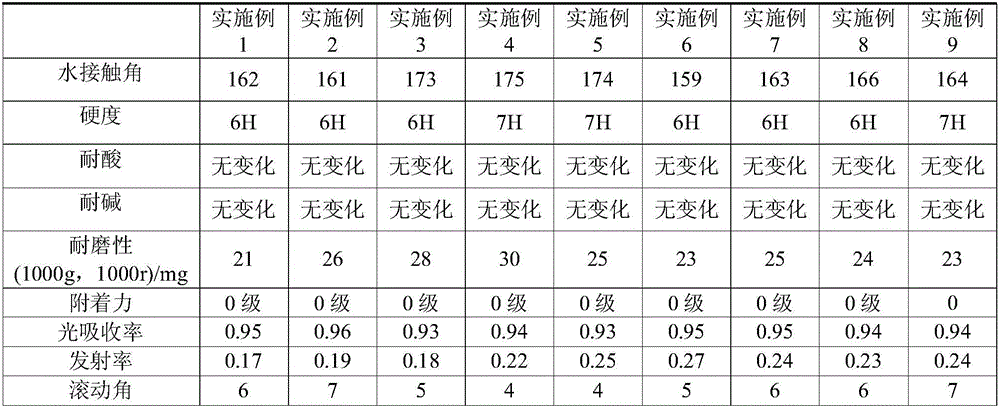

Examples

Embodiment 1

[0033] A method for improving the superhydrophobic performance of indoor power transformation equipment, comprising the following steps:

[0034] 1) Pretreatment: Pickle the metal surface of the indoor electrical substation equipment to be coated with a mixed solution of 8wt% hydrochloric acid and 8wt% sulfuric acid for 30 minutes; then neutralize with 3wt% sodium carbonate solution; Rinse the metal surface twice with clean water and dry; wherein, the volume ratio of hydrochloric acid and sulfuric acid is 1:0.8; the temperature of clean water is 25°C;

[0035] 2) Coating: apply the superhydrophobic nano-coating on the surface of the indoor substation equipment pretreated in step 1) by spin coating, and dry at 50° C. to complete the transformation of the superhydrophobic performance of the indoor substation equipment.

[0036] Among them, the super-hydrophobic nano-coating includes the following raw materials in parts by weight: 30 parts of fluorine-containing acrylic resin, 8 ...

Embodiment 2

[0041] A method for improving the superhydrophobic performance of indoor power transformation equipment, comprising the following steps:

[0042] 1) Pretreatment: Pickle the metal surface of the indoor substation equipment to be coated with a mixed solution of 10wt% hydrochloric acid and 10wt% sulfuric acid for 50 minutes; then neutralize with 5wt% sodium carbonate solution; Rinse the metal surface 3 times with clean water and dry; wherein, the volume ratio of hydrochloric acid and sulfuric acid is 1:1.2; the temperature of clean water is 35°C;

[0043] 2) Coating: apply the super-hydrophobic nano-coating on the surface of the indoor substation equipment pretreated in step 1) by dip coating, and dry at 80°C to complete the transformation of the super-hydrophobic performance of the indoor substation equipment.

[0044] Among them, the superhydrophobic nano-coating for indoor power transformation equipment includes the following raw materials in parts by weight: 50 parts of fluo...

Embodiment 3

[0049] A method for improving the superhydrophobic performance of indoor power transformation equipment, comprising the following steps:

[0050] 1) Pretreatment: Pickle the metal surface of the indoor substation equipment to be coated with a mixed solution of 9wt% hydrochloric acid and 9wt% sulfuric acid for 40 minutes; then neutralize with 4wt% sodium carbonate solution; Rinse the metal surface 3 times with clean water and dry; wherein, the volume ratio of hydrochloric acid and sulfuric acid is 1:1; the temperature of clean water is 30°C;

[0051] 2) Coating: The superhydrophobic nano-coating is coated on the surface of the indoor substation equipment pretreated in step 1) by spin coating, and dried at 65° C., which completes the transformation of the superhydrophobic performance of the indoor substation equipment.

[0052] Among them, the super-hydrophobic nano-coating includes the following raw materials in parts by weight: 40 parts of fluorine-containing acrylic resin, 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com