Alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer and preparation method thereof

A technology of methyl styrene and random copolymers, which is applied in the field of polymer polymerization, can solve the problems of inability to form functional grafts with copolymers, and achieve the effects of good processing performance, good heat resistance, and low melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The molar ratio of AMS and St is 3:5, wherein AMS is 3.6g, St is 5.2g, the solvent is butanone 10mL (monomer mass concentration 45%), the concentration of MAH solution is 0.5g / mL, and the total amount of MAH added is 1.8g, The initiator is 0.44 g of dibenzoyl peroxide (BPO). Heated in an oil bath, under the condition of 85°C nitrogen flow, after 10 minutes of reaction, MAH solution was added dropwise, one drop every 3 seconds, and samples were taken after 15 minutes, 30 minutes, 45 minutes, 60 minutes, 75 minutes, 90 minutes and 105 minutes of reaction respectively, and three A solution of a random copolymer, the solution is precipitated in methanol, centrifuged, and dried to obtain a white powder of α-methylstyrene-styrene-maleic anhydride ternary random copolymer. The conversion rate of the monomer measured by the gravimetric method increased with time, and the maleic anhydride content of the copolymer was basically maintained at a certain value by the acid-base titra...

Embodiment 2

[0059] AMS and St molar ratio 3:5, wherein AMS7.2g, St10.4g, solvent is butanone 24mL (monomer mass concentration 40%), MAH solution concentration is 0.5g / mL, MAH addition is 3.6g, triggers The agent is BPO0.88g. Heating in an oil bath, under the condition of 85°C nitrogen flow, start to add MAH solution dropwise after 10 minutes of reaction, drop every 3 seconds, add dropwise for 120 minutes, and continue to react for 30 minutes after dropping. After the reaction, the product was precipitated in methanol, suction filtered, and dried to obtain α-methylstyrene-styrene-maleic anhydride ternary random copolymer with a yield of 39.2%. The content of MAH in the copolymer was 28.8% as determined by acid-base titration, and the content of AMS in the copolymer as measured by elemental analysis was 18%. The molecular weight of the copolymer data is 12000 g / mol, and the molecular weight distribution coefficient is 2.3.

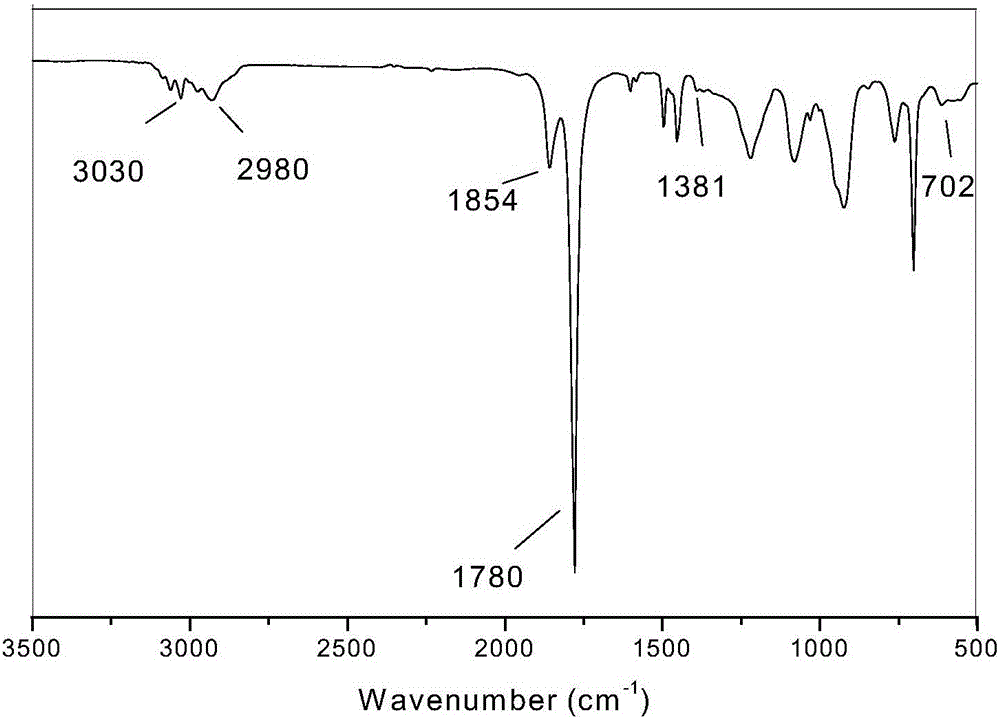

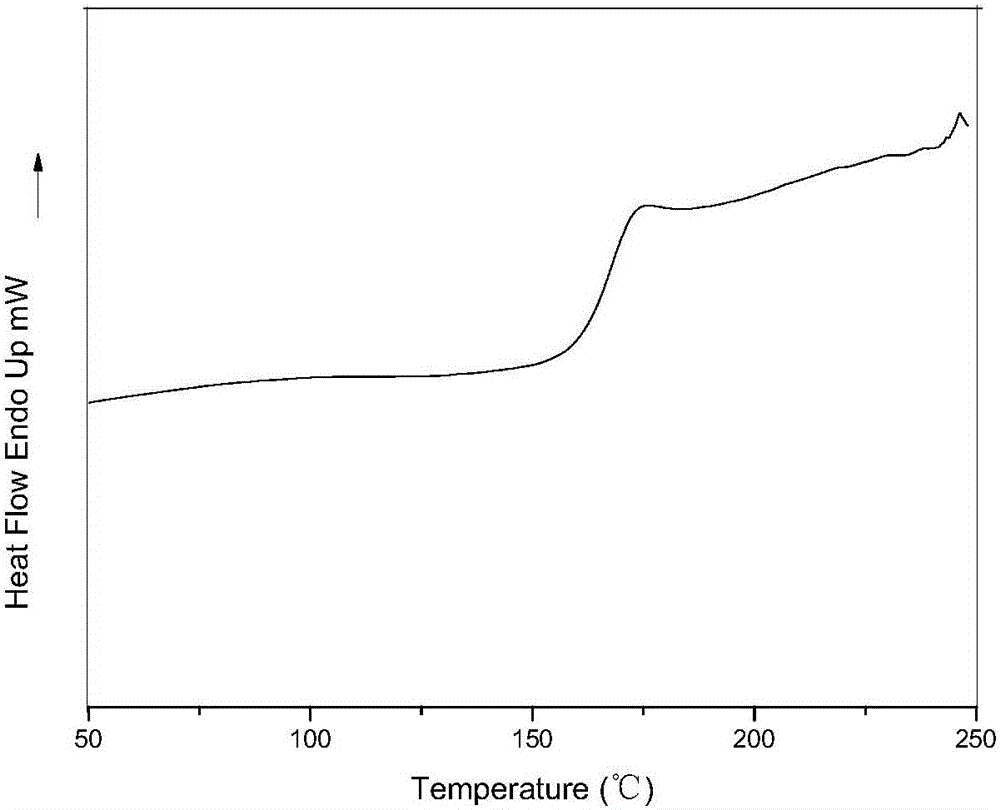

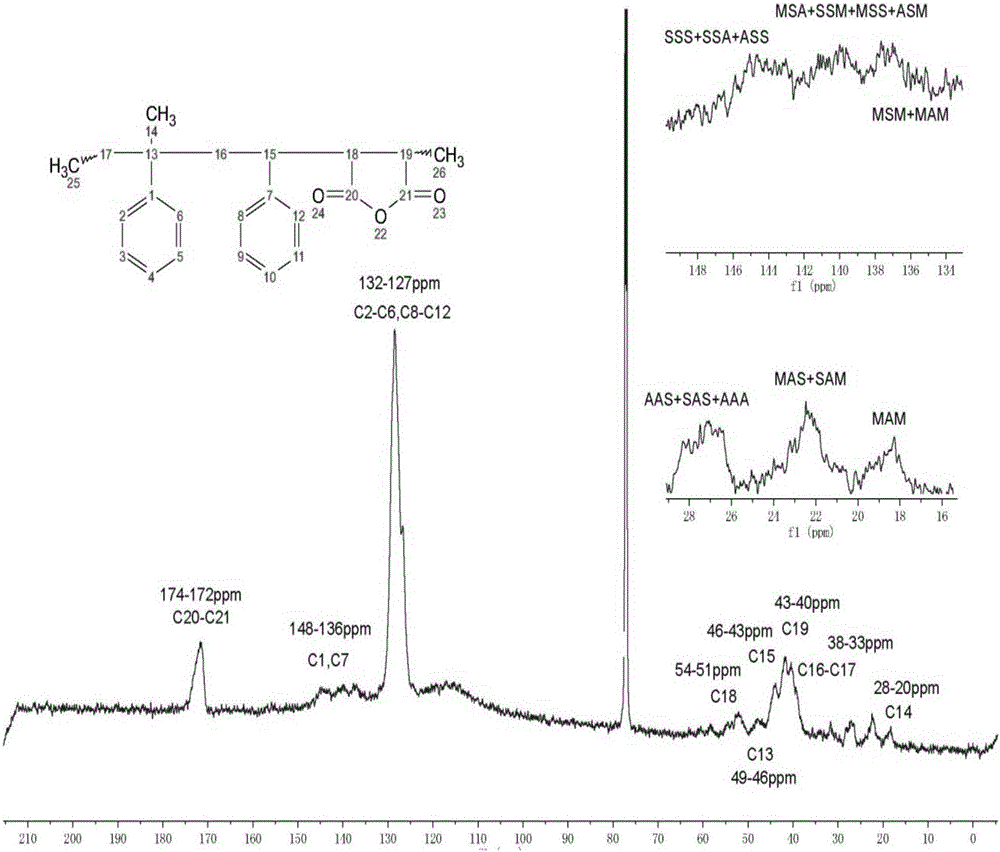

[0060] NMR of the prepared copolymer ( 13 C-NMR) spectrogram se...

Embodiment 3

[0062]AMS and St molar ratio 1:1, wherein AMS5.8g, St5.1g, solvent is butanone 24mL (monomer mass concentration 38%), MAH solution concentration is 0.5g / mL, MAH addition is 2.2g, triggers The agent is BPO0.61g. Under the condition of 85°C under nitrogen flow, after 10 minutes of reaction, the MAH solution was added dropwise, every 3 seconds, for 120 minutes, and the reaction was continued for 30 minutes after the dropwise addition. After the reaction, the product was precipitated in methanol, suction filtered, and dried to obtain α-methylstyrene-styrene-maleic anhydride ternary random copolymer with a yield of 36.2%. The content of MAH in the copolymer was 27.8% as measured by acid-base titration, and the content of AMS in the copolymer was 22.4% by elemental analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com