Method for treating refuse leachate membrane-concentrated liquid by using ozone advanced oxidation

A technology of landfill leachate and advanced oxidation, which is applied in anaerobic digestion treatment, oxidized water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of salt accumulation, expensive treatment, complicated equipment, etc., and achieve the speed of mud-water separation. Faster, lower processing costs, and no need for civil construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

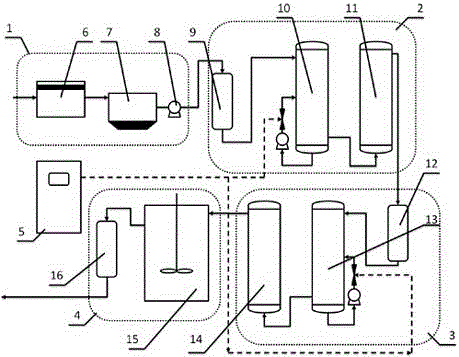

[0015] A method for treating landfill leachate membrane concentrate by using advanced ozone oxidation of the present invention comprises pretreatment 1, ozone catalytic oxidation treatment 2, advanced oxidation treatment 3 and denitrification treatment 4.

[0016] Such as figure 1 As shown, the landfill leachate membrane concentrate first enters pretreatment 1, and the landfill leachate membrane concentrate whose pH value is adjusted to 8-11 is fully mixed with metal salt inorganic polymer flocculants and polyacrylamide to form flocs and Transported to the air flotation machine 6, in the air flotation machine 6, the flocs formed by the metal salt inorganic polymer flocculant and the micro-bubbles produced by the air flotation machine 6 adhere together and float quickly to realize the separation of mud and water; appropriate amount of metal salt The inorganic polymer flocculant not only effectively removes organic matter with a molecular weight greater than 1000 atomic mass uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com