Copper material smelter harmful waste gas purifying device

A waste gas purification device and furnace technology, which is applied to furnaces, waste heat treatment, furnace components, etc., can solve problems such as adverse effects of the surrounding environment, injury of workers, and harmful components escaping into narrow indoor spaces, and achieve the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

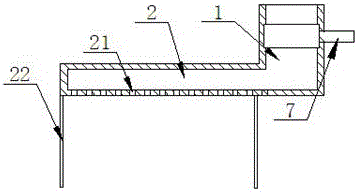

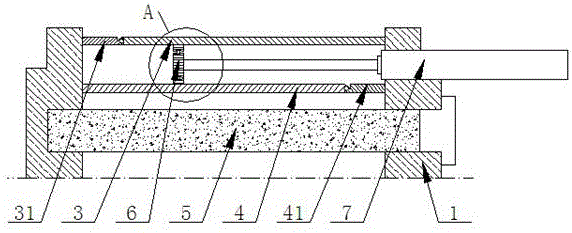

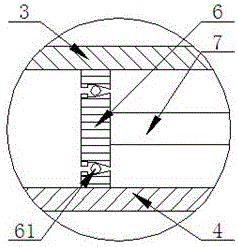

[0014] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention.

[0015] Such as Figure 1-3 As shown, a harmful exhaust gas purification device for a copper melting furnace includes a harmful exhaust gas exhaust pipe 1, a negative pressure generator is arranged in the harmful exhaust gas exhaust pipe 1, and a plate is arranged at the bottom of the harmful exhaust gas exhaust pipe 1 Shaped air distribution box 2, the bottom of the plate-shaped air distribution box 2 is uniformly provided with some air distribution and suction holes 21; the negative pressure generator includes an upper partition 3 and a lower partition 4, and the upper partition 3 and the The lower partition 4 divides the harmful exhaust gas suction pipe 1 from top to bottom into an upper exhaust part, a middle suction blowing part and a lower suction part. 5, and a piston 6 that can move horizontally and a cylinder 7 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com