A kind of self-cleaning optical resin lens and preparation method thereof

An optical resin lens, self-cleaning technology, applied in optics, optical parts, optical components, etc., can solve the problems of not being able to achieve large-scale mass production, achieve good self-cleaning ability, efficient preparation method, and facilitate mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

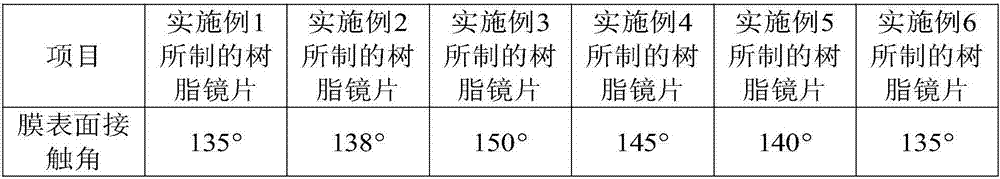

Examples

Embodiment 1

[0033] A method for preparing a self-cleaning optical resin lens, comprising the following steps:

[0034] Step S01, cleaning: immerse the resin substrate in absolute ethanol for 2 hours, take it out, place it in a vacuum drying oven, and dry it at 35° C. for 1 hour to obtain the resin substrate I;

[0035] Step S02, microwave hydrothermal reaction: put ZnO nanopowder with a particle size of 50nm and polyethylene oxide into a sodium hydroxide solution at a mass percentage of 15:1, move the system into a polytetrafluoroethylene reactor, and The temperature is 130°C, the reaction pressure is 0.2MPa, and the reaction power is 300W, and the microwave hydrothermal reaction is carried out for 30 minutes. After the reaction, the reaction system is naturally cooled to room temperature; the quality of the sodium hydroxide solution is the input ZnO nano powder 30 times the total mass of the body and polyethylene oxide to obtain a nano-ZnO solution;

[0036] Step S03, film formation: Sl...

Embodiment 2

[0041] A method for preparing a self-cleaning optical resin lens, comprising the following steps:

[0042] Step S01, cleaning: immerse the resin substrate in absolute ethanol for 4 hours, take it out, place it in a vacuum drying oven, and dry it at 42°C for 3 hours to obtain the resin substrate I;

[0043] Step S02, microwave hydrothermal reaction: put ZnO nanopowder with a particle size of 120 nm, triglyceride stearate, and tetraphenylphosphonium bromide into the diethylenetriamine solution at a mass percentage of 20:1:0.5, Move the system into a polytetrafluoroethylene reactor, conduct a microwave hydrothermal reaction for 60 minutes at a temperature of 150 ° C, a reaction pressure of 1.8 MPa, and a reaction power of 1500 W. After the reaction, the reaction system is naturally cooled to room temperature; The quality of the diethylenetriamine solution is 60 times the total mass of the input ZnO nanopowder, triglyceride stearate and tetraphenylphosphonium bromide to obtain a n...

Embodiment 3

[0049] A method for preparing a self-cleaning optical resin lens, comprising the following steps:

[0050] Step S01, cleaning: immerse the resin substrate in absolute ethanol for 3 hours, take it out, place it in a vacuum drying oven, and dry it at 38° C. for 2 hours to obtain the resin substrate I;

[0051] Step S02, microwave hydrothermal reaction: combine ZnO nanopowder with a particle size of 85nm with tetrabutylphosphonium hydroxide, polyoxyethylene lauryl ether, and sorbitan fatty acid ester according to the mass ratio of 18:0.5:0.4:0.35 Put the percentage into the ethylenediamine solution, move the system into a polytetrafluoroethylene reactor, and conduct a microwave hydrothermal reaction for 45min under the conditions of a temperature of 140°C, a reaction pressure of 1.0MPa, and a reaction power of 900W. After the reaction, the The reaction system is naturally cooled to room temperature; the quality of the ethylenediamine solution is 45 times the total mass of the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com