Gate oxide layer failure analysis method

A gate oxide layer and failure analysis technology, which is applied in the direction of material analysis by measuring secondary emissions, can solve the problems of indistinguishable contrast of heavy metal elements, inability to clearly observe the position of heavy metal pollution, inability to perform elemental analysis, etc. To achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

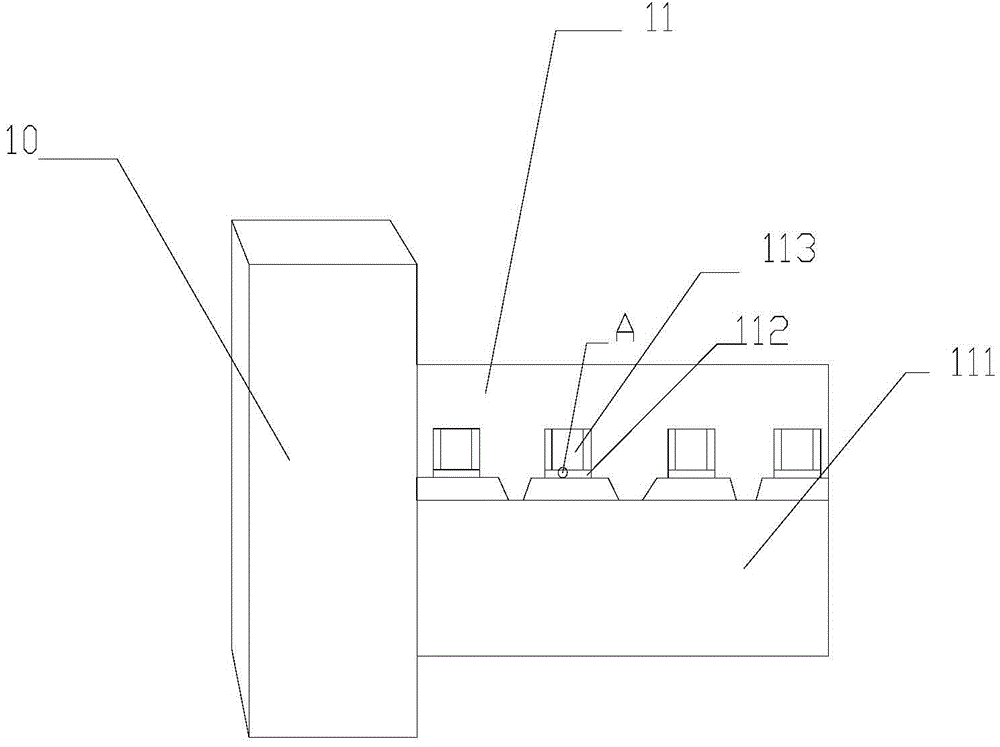

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0037] Figure 6 is a schematic flow chart of the gate oxide layer failure analysis method in the embodiment of the present invention, as Figure 6 Shown:

[0038] This embodiment relates to a failure analysis method for a gate oxide layer, comprising the following steps:

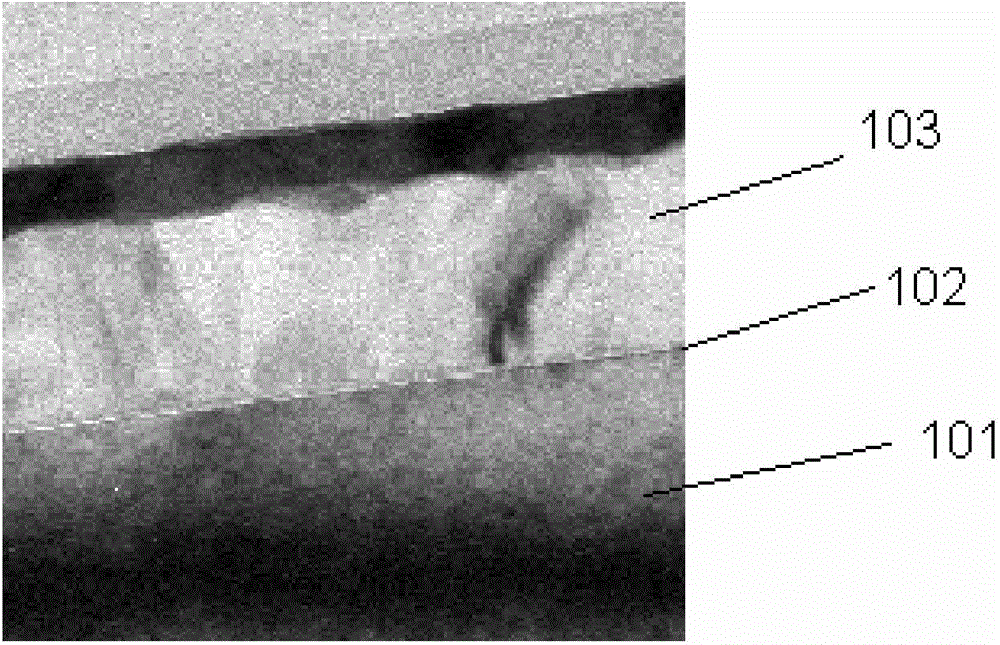

[0039] Step S1, providing a semiconductor device to be tested that includes a gate oxide layer and a polysilicon gate covering the surface of the gate oxide layer, and there is heavy metal pollution between the gate oxide layer and the polysilicon gate. Preferably, the material of the gate oxide layer is silica.

[0040] In step S2, the area contaminated by heavy metals on the semiconductor device to be tested is prepared as a TEM sample. Preferably, a focused ion beam is used to prepare a TEM sample from the area contamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com