A measure-in and measure-out double calibration device and method for calibrating the volume of a horizontal metal tank

A calibration device and metal tank technology, applied in the field of measurement, can solve the problems of large volume calibration errors and low efficiency of metal storage tanks, and achieve the effects of saving equipment investment, simple operation and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

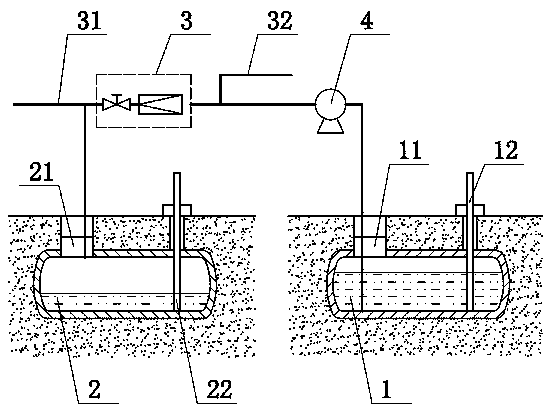

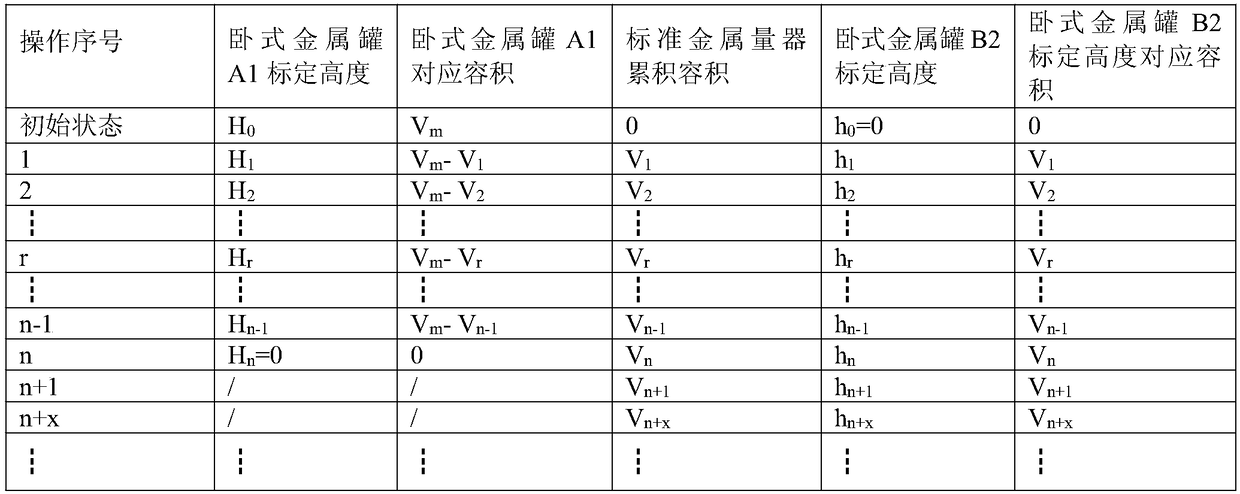

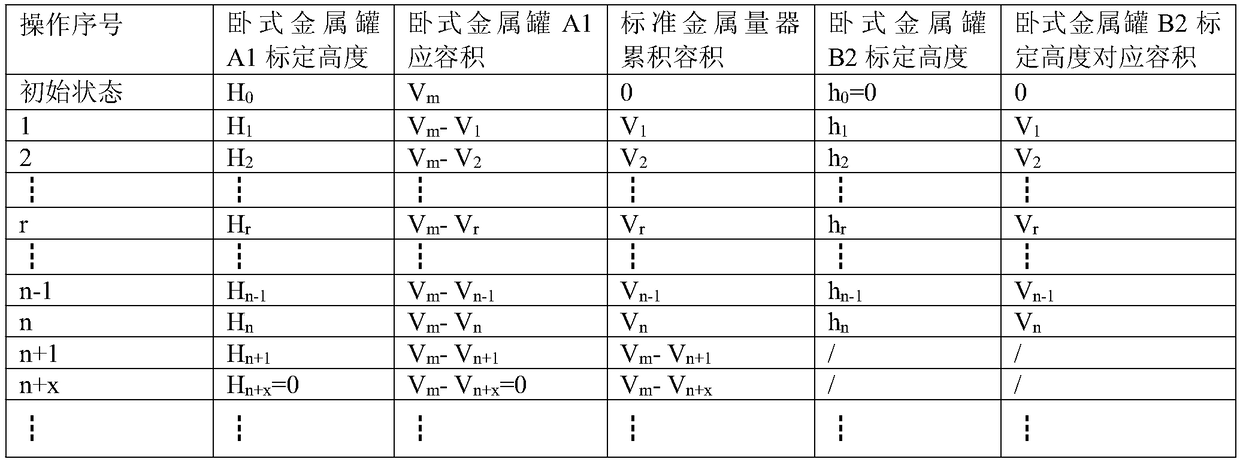

[0023] like figure 1 As shown, a measure-in and measure-out dual calibration device for calibrating the volume of a horizontal metal tank includes: a horizontal metal tank A1, a horizontal metal tank B2, a standard device 3 and a water pump 4. Horizontal metal tank A1 and horizontal metal tank B2 are oil storage tanks to be calibrated, buried below the ground. The horizontal metal tank A1 is provided with a manhole A11 and an oil measuring hole A. The upper ends of the manhole A11 and the oil measuring hole A are respectively exposed to the ground, and the lower ends are respectively communicated with the inner cavity of the horizontal metal tank A1. The bottom surface of the inner cavity of the horizontal metal tank A1 is provided with a measurement reference point of the tank A, and the measurement reference point of the tank A is located directly below the oil measuring hole A. The horizontal metal tank A1 is connected with a liquid level gauge A12, and the liquid level g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com