Sliding sheet type overpressure recovery equipment

A recovery equipment, sliding vane technology, used in mechanical equipment, rotary piston pumps, rotary piston machines, etc., can solve the problem that the solenoid valve cannot form a reliable mechanical interlock, the single-machine processing capacity is small, and the fluid flow rate fluctuation is increased. issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

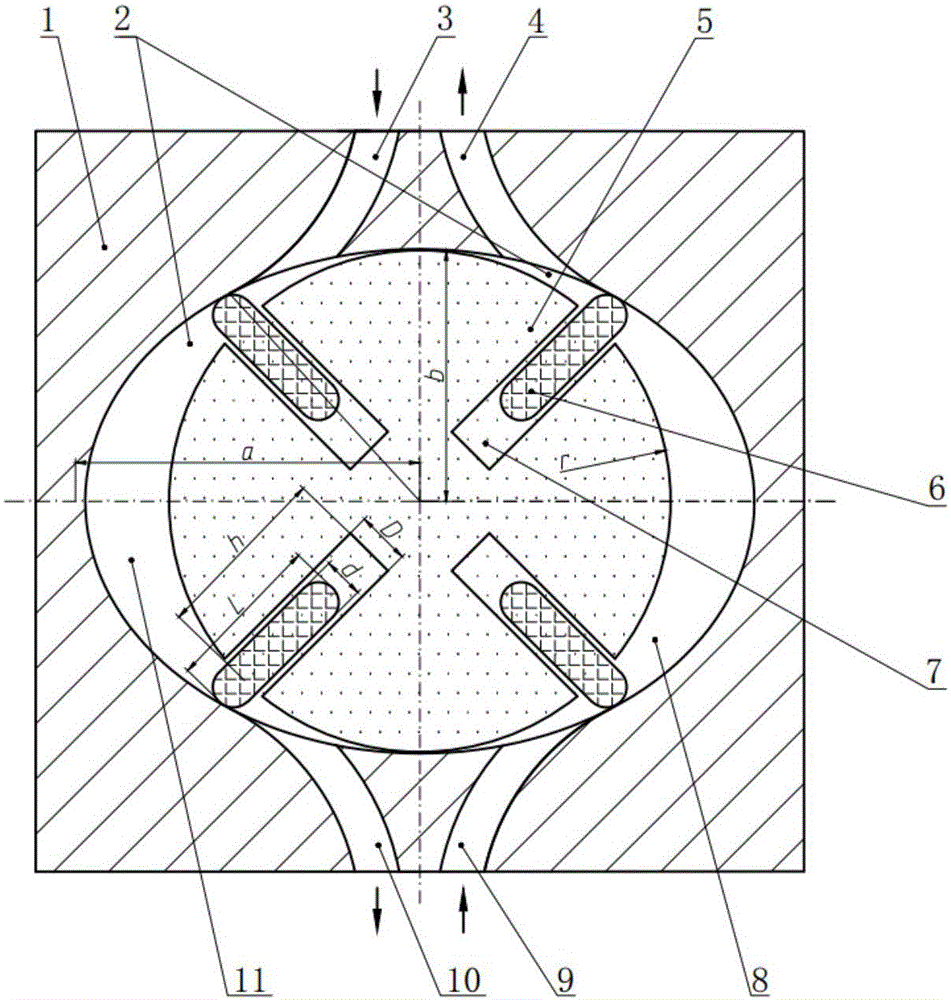

[0048] see figure 1 , a sliding vane type residual pressure recovery device, comprising a cylinder 1, a rotor 5 is arranged in the inner chamber 2 of the cylinder 1, and the rotor 5 divides the inner chamber 2 into a left chamber 11 and a right chamber 8, and the left chamber The upper and lower ends of the chamber 11 communicate with the high-pressure inlet hole 3 and the low-pressure outlet hole 10 respectively, and the upper and lower ends of the right chamber 8 communicate with the high-pressure outlet hole 4 and the low-pressure inlet hole 9 respectively. The rotor 5 is provided with a plurality of slots 7, and the sliding vanes 6 are arranged in the slots 7, and the rotor profile of the rotor 5 is circular.

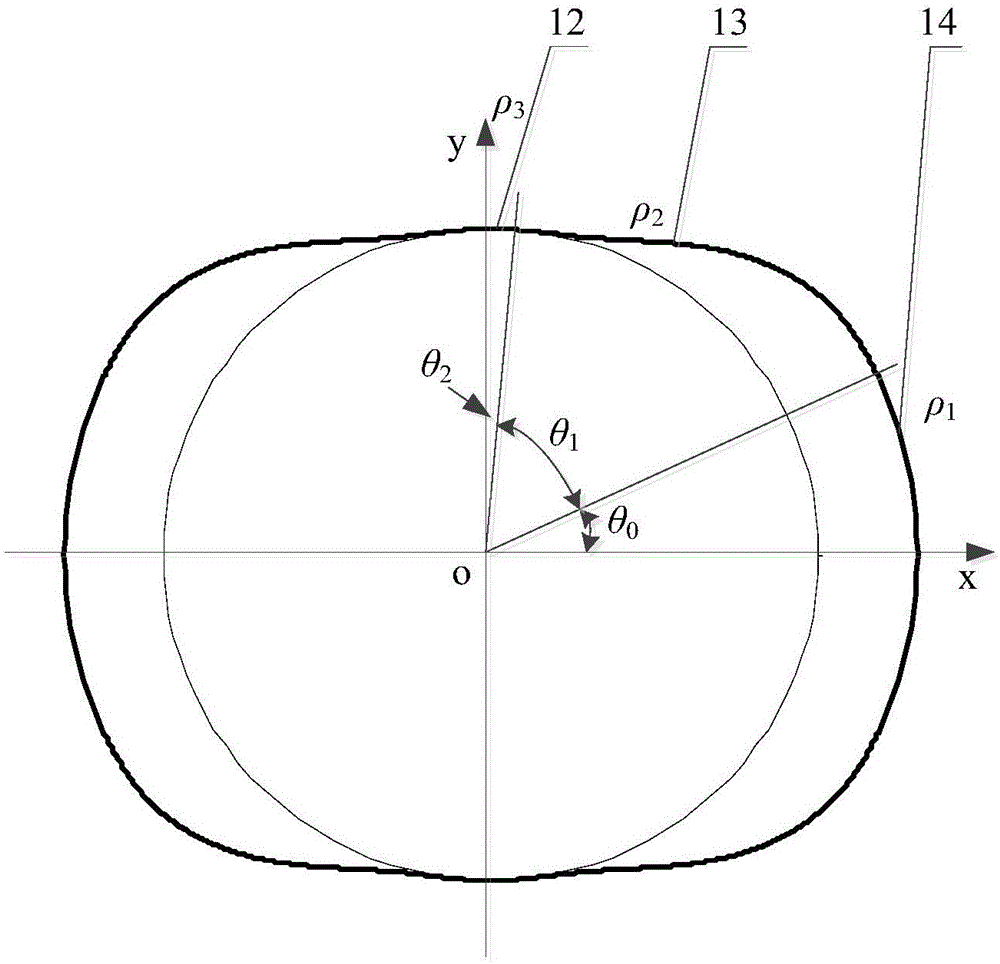

[0049] The main curve sections of the cylinder body molding lines in the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com