A Submerged Underground Excavation Construction Method of Rectangular or Quasi-rectangular Section Underground Engineering Machinery

An underground engineering and construction method technology, applied in underground chambers, earthwork drilling, mining equipment, etc., can solve the problems of low construction efficiency, environmental damage, and high safety risks of mining methods, achieve good economy, and avoid blocking roads. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: A subsurface excavation construction method for underground construction machinery with a rectangular or quasi-rectangular section, comprising the following steps:

[0045] Step 1: Structurally divide the overall structure of the underground engineering with a rectangular or quasi-rectangular section. The structure on the soil-facing surface is divided into peripheral structures, and the rest of the structures are divided into internal structures; the peripheral structure is divided into several sub-structures with a cut plane perpendicular to the rectangular or similar rectangular section; when the sub-structure is divided, for the convenience of later construction of the internal structure When dividing the peripheral structure, the cut plane should avoid the joints between the peripheral structure and the internal structure.

[0046] Step 2: perform block prefabrication of each sub-structure in the longitudinal direction perpendicular to the section pla...

Embodiment 2

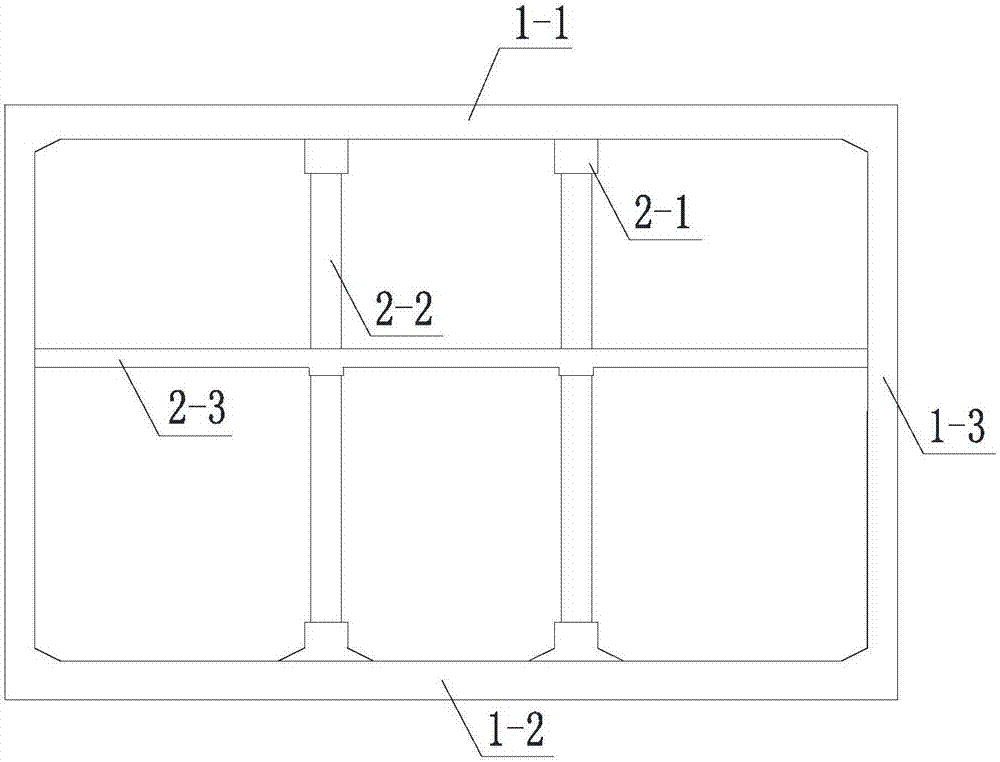

[0056] Embodiment 2: as figure 1 As shown, the two-column three-span underground space project with a rectangular section has an overall structure composed of a peripheral structure 1 and an internal structure 2. -1, column 2-2 and plate 2-3.

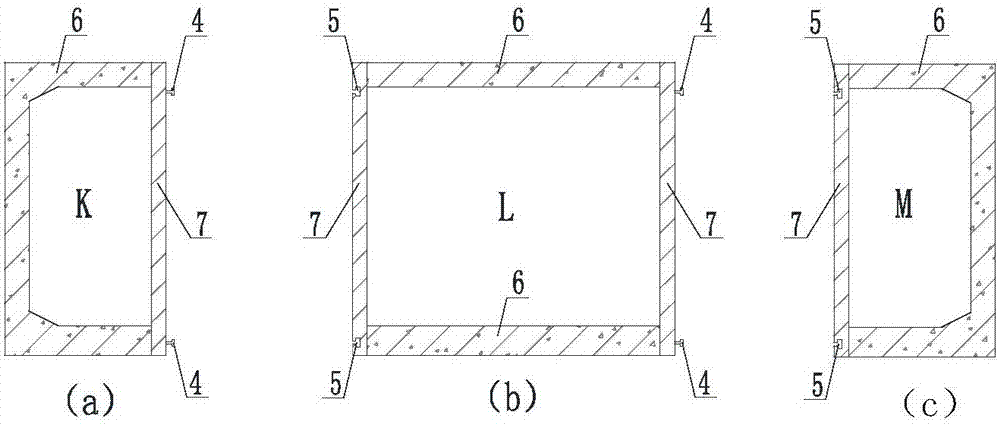

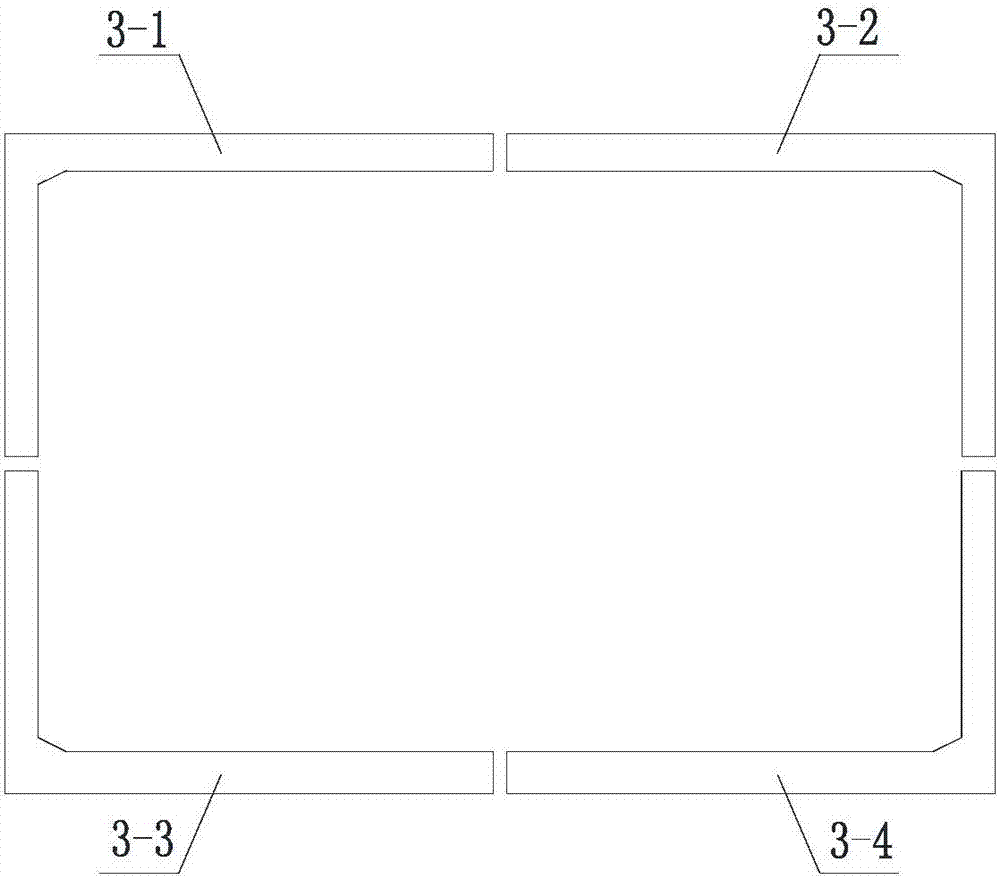

[0057] Step one, such as figure 2 As shown, the peripheral structure of the two-column three-span rectangular section underground space project is divided into four sub-structures with the same section size: sub-structure I3-1, sub-structure II3-2, sub-structure III3- 3. Divisional structure Ⅳ3-4. When dividing the divisional structure, for the convenience of the later construction of the internal structure, when dividing the peripheral structure, the cutting plane should avoid the peripheral structure (top plate 1-1, bottom plate 1-2 and side Wall 1-3) and internal structure 2 (beam 2-1, column 2-2 and slab 2-3).

[0058] Step 2: Prefabricate each substructure 3 in blocks, and each substructure obtains several prefabricated parts i...

Embodiment 3

[0068] like Figure 7 As shown, the single-column double-span rectangular-section underground space project, the ground conditions of the site are soft soil strata such as silt and clay, the cross-sectional size is 20.7m (width) × height 13.3m, and the longitudinal length of the overall structure is 200m; the overall structure is composed of The outer peripheral structure 15 and the inner structure 16 are composed, the outer peripheral structure 15 is in contact with the surrounding soil, including the top plate 15-1, the bottom plate 15-2 and the side wall 15-3; the inner structure includes the longitudinal beam 16-1, the column 16-2 and the middle Plate 16-3.

[0069] Step one, such as Figure 8 As shown, the outer peripheral structure 15 of the single-column double-span rectangular section underground space project is divided, and the cut plane avoids the outer peripheral structure 15 (roof 15-1, bottom 15-2 and side wall 15-3) and the internal structure 16 (longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com