Silicon ingot and preparation method thereof

A silicon ingot and silicon material technology, applied in the field of solar cell materials, can solve problems such as uneven distribution of resistivity of silicon ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

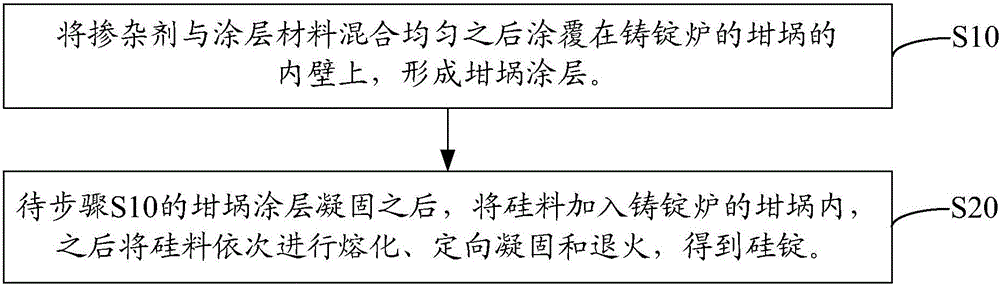

[0023] like figure 1 Shown, the preparation method of the silicon ingot of one embodiment, comprises the steps:

[0024] S10, uniformly mixing the dopant and the coating material and then coating the inner wall of the crucible of the ingot furnace to form a crucible coating.

[0025] The quality of the dopant depends on the target resistivity of the silicon ingot. For example, if the target resistivity of the boron-doped silicon ingot is 1.7Ω, the mass ratio concentration of boron is calculated to be 70ppbw. If the mass of the silicon material in the crucible is 850kg, Then the mass of boron element required is 0.06g. The photoelectric performance of the prepared silicon ingot can be better controlled by precise calculation.

[0026] The dopant is selected from at least one of a master alloy and a semiconductor element. The master alloy is an alloy of impurity elements and silicon. In a preferred embodiment, the master alloy is selected from at least one of gallium-silicon ...

Embodiment 1

[0042]18g of gallium, 620g of silicon nitride, 350ml of silica sol, 50g of binder and 1200ml of pure water were mixed and stirred evenly, and then sprayed on the inner wall of the crucible of the ingot furnace to form a crucible coating.

[0043] After the coating of the crucible is solidified, add 850kg of silicon material into the crucible, and then put the crucible filled with silicon material into the ingot furnace.

[0044] Vacuum the ingot furnace, then heat the silicon material to 1175°C, maintain the pressure in the ingot furnace at 600mbar, and then raise the temperature to 1510°C to melt the silicon material from top to bottom.

[0045] After the silicon material is melted, it enters the crystal growth stage, and the silicon ingot is directional solidified from bottom to top by opening the steel cage and lowering the temperature in the furnace.

[0046] After the crystal growth is completed, the silicon ingot of Example 1 can be obtained after annealing and cooling. ...

Embodiment 2

[0059] 200g of borosilicate alloy (containing 0.06g of boron), 620g of silicon nitride, 330ml of silica sol, 45g of binder and 1100ml of pure water were mixed and stirred evenly, and then sprayed on the inner wall of the crucible of the ingot furnace to form a crucible coating.

[0060] After the coating of the crucible is solidified, the silicon material is added into the crucible of the ingot furnace, and then the crucible filled with the silicon material is put into the ingot furnace.

[0061] Vacuum the ingot furnace, then heat the silicon material to 1160°C, maintain the pressure in the ingot furnace at 600mbar, and then raise the temperature to 1535°C to melt the silicon material from top to bottom.

[0062] After the silicon material is melted, it enters the crystal growth stage, and the silicon ingot is directional solidified from bottom to top by opening the steel cage and lowering the temperature in the furnace.

[0063] After the crystal growth is completed, the sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com