As-cast high-strength ductile iron and preparation method thereof

A nodular cast iron, high-strength technology, applied in the field of nodular cast iron, can solve the problem that the strength of nodular cast iron is difficult to meet the actual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

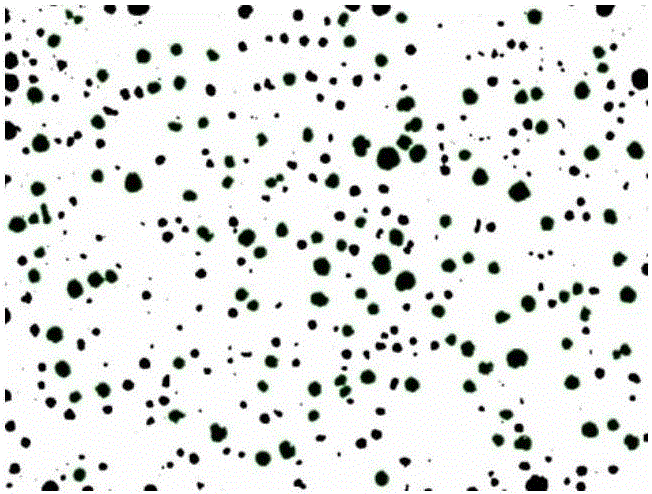

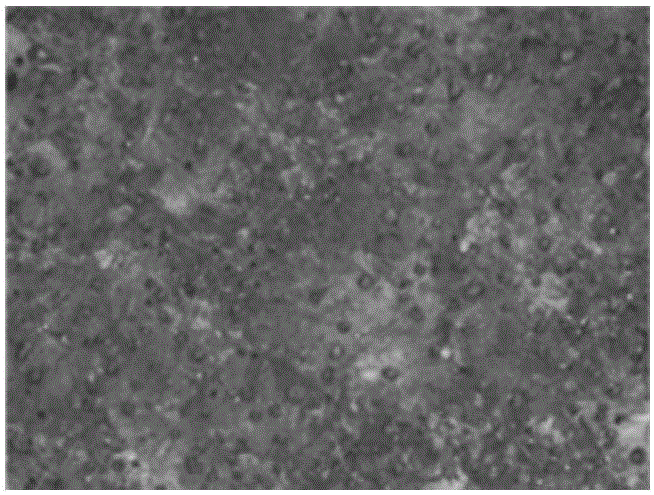

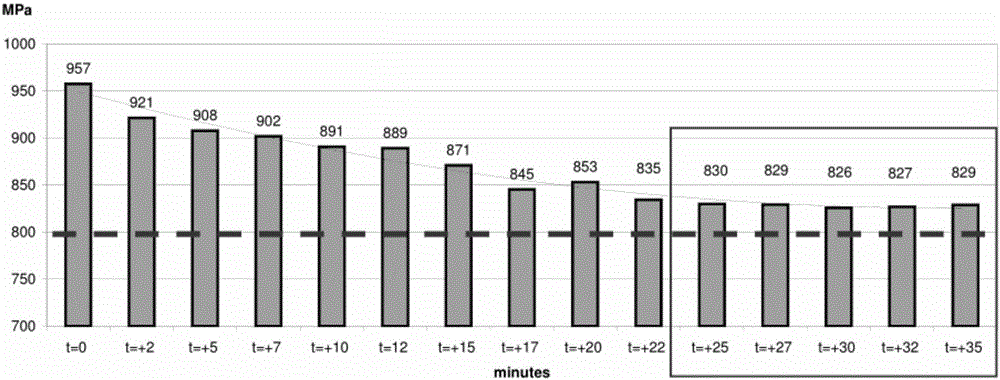

Image

Examples

preparation example Construction

[0021] The present invention also provides a method for preparing the as-cast high-strength nodular cast iron as described above, comprising:

[0022] 1) Preheat the steel scrap and returned materials at 1050-1150°C;

[0023] 2) Melting the preheated raw materials at 1500-1550°C to make molten iron;

[0024] 3) adding rare earth nodulizer and inoculant into molten iron and stirring to obtain inoculated molten iron;

[0025] 4) adding the flow inoculant into the inoculated molten iron and casting to obtain as-cast high-strength nodular cast iron;

[0026] Among them, the rare earth spheroidizer contains rare earth elements, magnesium, calcium, barium, silicon, iron and impurity elements; the inoculant contains silicon, aluminum, barium, carbon and impurity elements; the flow inoculant contains silicon, aluminum, bismuth, carbon and impurity elements.

[0027] In the above preparation method, the specific components of the rare earth nodulizer, inoculant and flow inoculant ca...

Embodiment 1

[0034] 1) Mix the steel scrap and the returned material according to the weight ratio of 100:80, and then preheat at 1100°C for 0.3h;

[0035] 2) melting the preheated raw material at 1530°C for 1 hour to obtain molten iron;

[0036] 3) Rare earth spheroidizing agent (containing 2% by weight of lanthanum, 8% by weight of magnesium, 3% by weight of calcium, 2% by weight of barium, 45% by weight of silicon, and the balance is iron and impurity elements), an inoculant (containing 75% by weight of silicon, 1% by weight of aluminum, 2.6% by weight of barium, and the balance being carbon and impurity elements) is added to molten iron and stirred to obtain inoculated molten iron, wherein the addition of the rare earth spheroidizer is 1% by weight, the addition of inoculant is 0.1% by weight;

[0037] 4) Add the flow inoculant (containing 75% by weight of silicon, 1% by weight of aluminum, 3.5% by weight of bismuth, and the balance is carbon and impurity elements) into the inoculated...

Embodiment 2

[0039] 1) Mix the steel scrap and the returned material according to the weight ratio of 100:75, and then preheat at 1050°C for 2 hours;

[0040] 2) melting the preheated raw material at 1500°C for 1 hour to produce molten iron;

[0041] 3) Rare earth spheroidizing agent (containing 0.5% by weight of cerium, 5% by weight of magnesium, 1% by weight of calcium, 1% by weight of barium, 40% by weight of silicon, and the balance is iron and impurity elements), an inoculant (containing 70% by weight of silicon, 0.5% by weight of aluminum, 2.2% by weight of barium, and the balance being carbon and impurity elements) is added to molten iron and stirred to obtain inoculated molten iron, wherein the addition of the rare earth spheroidizing agent is 0.5% by weight, the addition of inoculant is 0.15% by weight;

[0042] 4) Add the flow inoculant (containing 70% by weight of silicon, 0.5% by weight of aluminum, 3.2% by weight of bismuth, and the balance is carbon and impurity elements) in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com