Addition type solidifiable polysiloxane composition

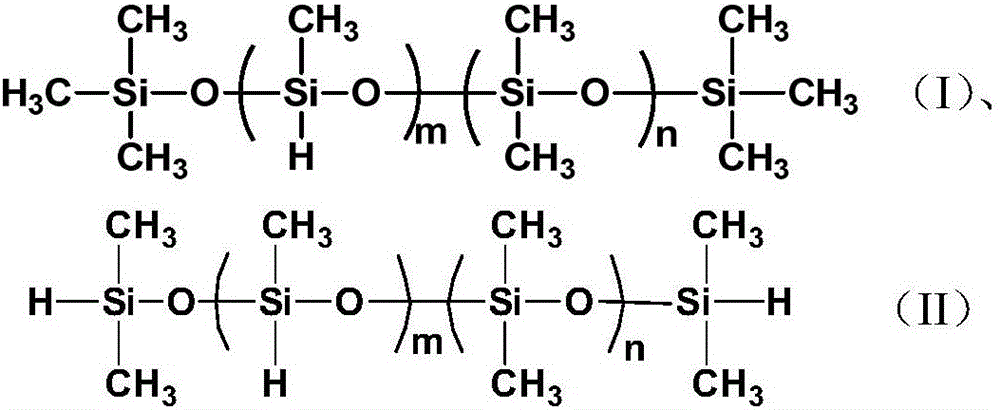

A technology of polysiloxane and hydrogen polysiloxane, which is applied in the field of addition-type curable polysiloxane composition, and can solve problems such as poor dispersion performance, poor dispersion, and inability to meet environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

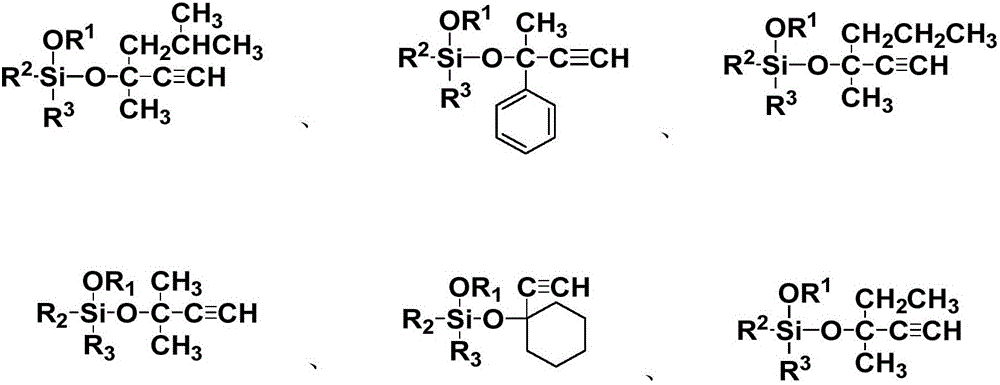

Method used

Image

Examples

Embodiment 1

[0031] 100 parts of α, ω-divinylpolydimethylsiloxane with a viscosity of 200mPa·s (25 degrees, measured by a rotational viscometer), 0.03 part of Karstedt catalyst (platinum-1,3-divinyltetramethyl Disiloxane complex, 3ppmPt), 0.01 part of (3,5-dimethyl-1-hexyne-3-oxyl)methyldimethoxysilane and 5.0 parts of organic hydrogenated The polysiloxane is mixed evenly in the container (the molar ratio of Si-H to SiVi is 1.7).

[0032]

Embodiment 2

[0034] Replace 0.01 part of (3,5-dimethyl-1-hexyne-3-oxyl)methyldimethoxysilane in Example 1 with 0.01 part of (3,5-dimethyl-1-hexyl Alkyne-3-oxyl)γ-methacryloxypropyldimethoxysilane. At the same time, 10 parts of hexamethyldisilazane modified white carbon black were added.

Embodiment 3

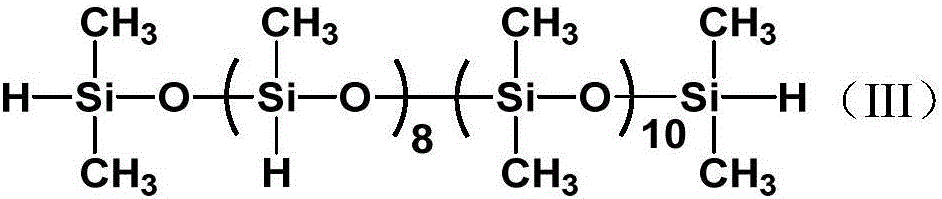

[0036] 100 parts of α, ω-divinylpolydimethylsiloxane with a viscosity of 1000mPa·s (25 degrees, measured by a rotational viscometer), 0.1 part of Karstedt catalyst (platinum-1,3-divinyltetramethyl Disiloxane complex, 10ppmPt), 0.1 parts of (3-phenyl-1-butyne-3-oxyl)(2,3-glycidoxy)propyldimethoxysilane and 3 parts of The organohydrogenpolysiloxane of the structural formula (IV) is uniformly mixed in the container (the molar ratio of Si-H to SiVi is 1.6).

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com