A kind of preparation method of cationic waterborne polythiourethane

A polythiourethane, cationic technology, applied in the field of water-based polyurethane, can solve the problem of no cationic water-based polythiourethane preparation, etc., to achieve the effect of good mechanical properties, good environmental protection, and excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

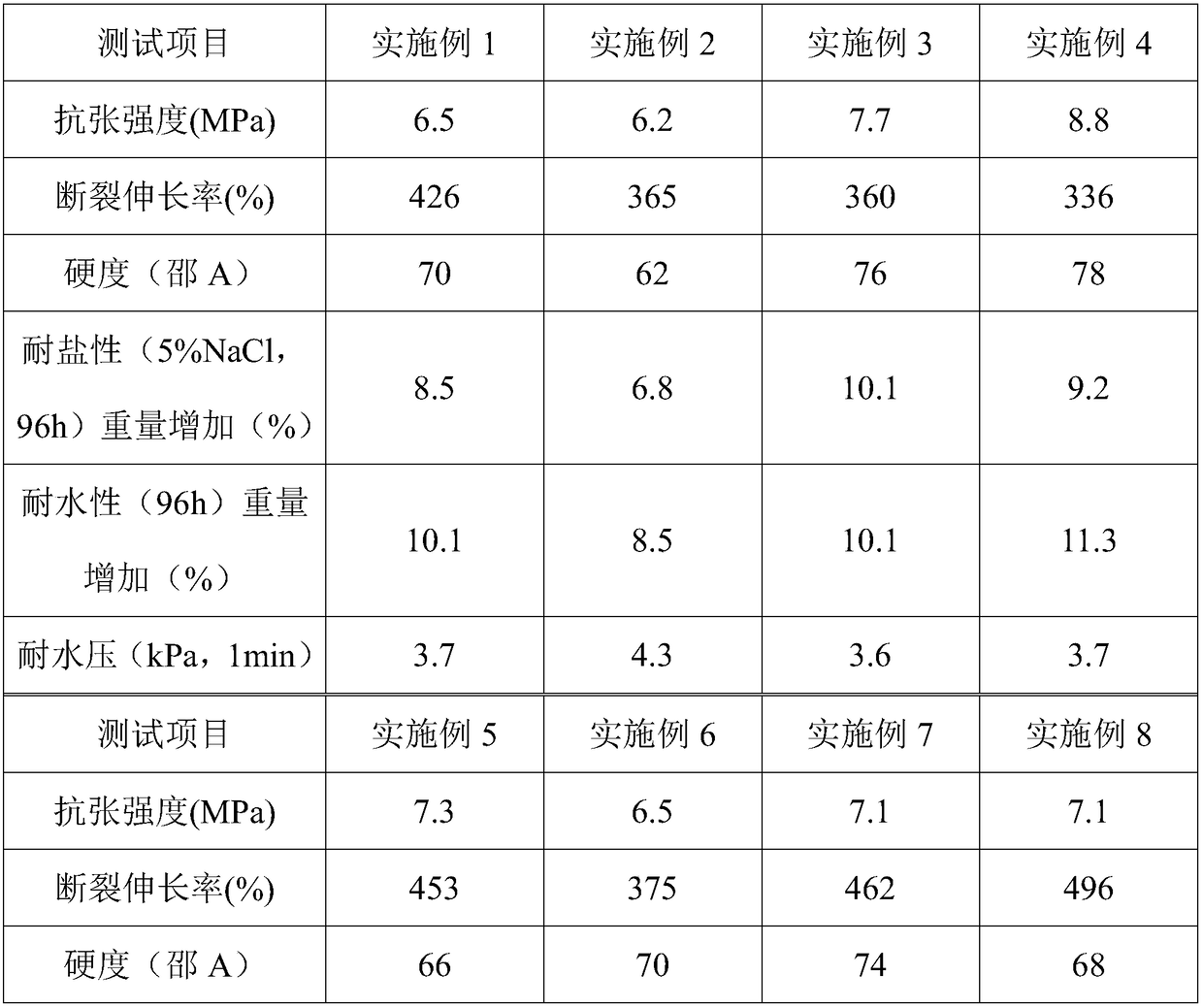

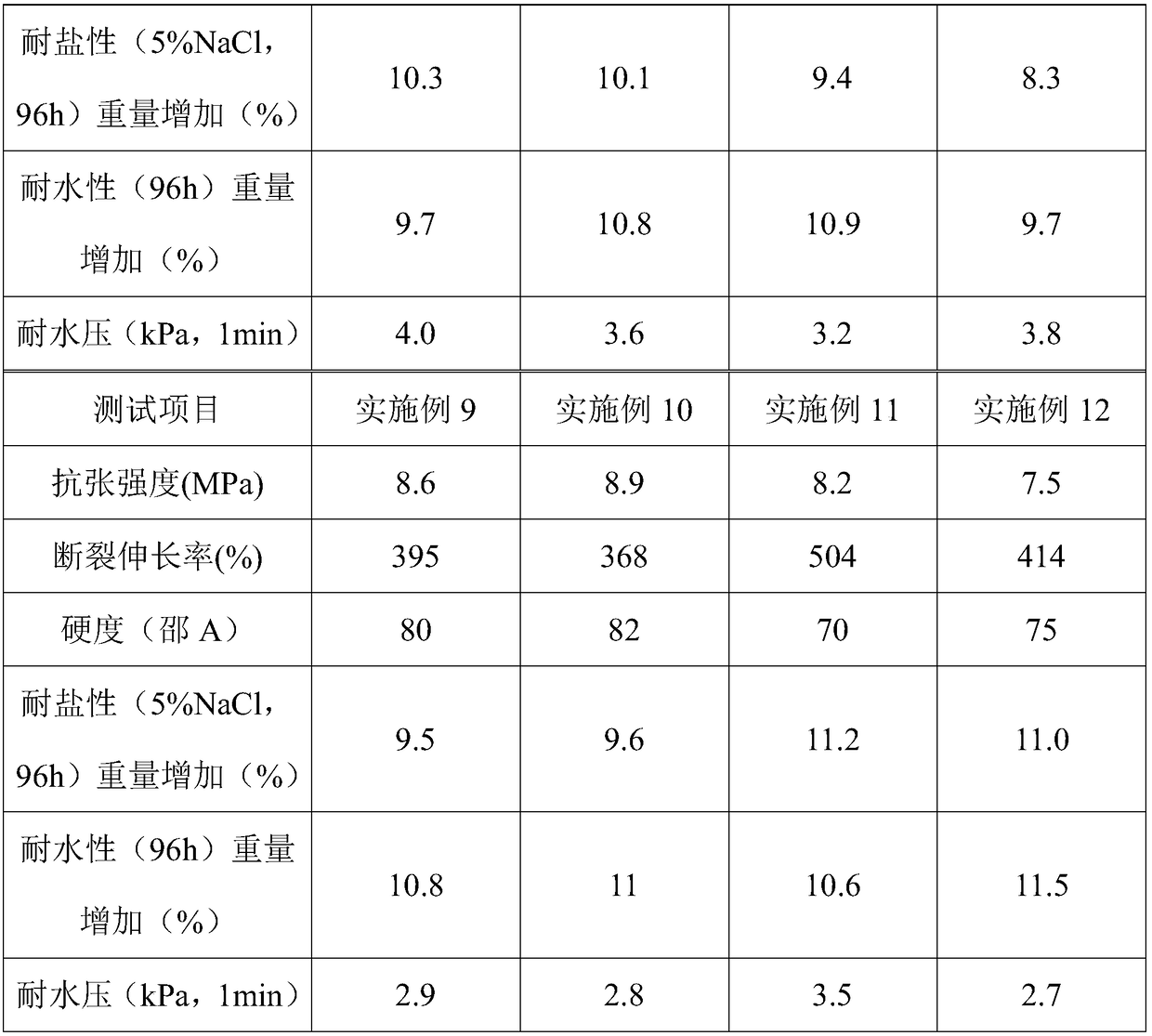

Embodiment 1

[0048] A kind of preparation method of cationic waterborne polythiourethane that the present invention proposes, comprises the steps:

[0049] S1. Add 58.1g of isophorone diisocyanate to 14.3g of liquid polysulfide rubber LP3 and 36.5g of polyoxypropylene diol mixed solution with a number average molecular weight of 1000 after vacuum dehydration at 110°C for 1 hour, and fill it with dry nitrogen to carry out Protect, heat up to 95°C, and keep warm for 180min to obtain the isocyanate-terminated polysulfide-modified polyurethane prepolymer;

[0050] S2. Cool the isocyanate-terminated polysulfide-modified polyurethane prepolymer to 40°C, then add 15.5g of diethylene glycol, 0.95g of trimethylolpropane, 0.1g of stannous octoate, and 0.12g of dilaurate Butyl tin and 20mL acetone, heat up to 80°C, keep warm for 150min, cool down to 35°C, then slowly add dropwise a mixed solution of 6.8g N-methyldiethanolamine and 15mL acetone, keep the temperature at 50°C, keep warm for 90min, then ...

Embodiment 2

[0053] A kind of preparation method of cationic waterborne polythiourethane that the present invention proposes, comprises the steps:

[0054] S1. Add 58.1g of isophorone diisocyanate to 50g of liquid polysulfide rubber LP3 that has been vacuum dehydrated at 110°C for 1 hour, fill it with dry nitrogen for protection, raise the temperature to 95°C, and keep it warm for 180min to obtain polysulfide modified with terminal isocyanate groups. Polyurethane prepolymer;

[0055] S2. Cool the isocyanate-terminated polysulfide-modified polyurethane prepolymer to 40°C, then add 14.6g of dipropylene glycol, 0.9g of glycerin, 0.11g of stannous octoate, 0.12g of dibutyltin dilaurate and 25mL of acetone, Heat up to 80°C, keep it warm for 150min, cool down to 35°C, then slowly add a mixed solution of 6.9g N-methyldiethanolamine and 15mL of acetone dropwise, keep the temperature at 50°C, keep it warm for 90min, then add 40mL of acetone to reduce the viscosity to obtain isocyanate Polysulfide-...

Embodiment 3

[0058] A kind of preparation method of cationic waterborne polythiourethane that the present invention proposes, comprises the steps:

[0059] S1. Add 45.1g of dicyclohexylmethane diisocyanate to 10g of liquid polysulfide rubber LP3, 12.3g of polytetrahydrofuran ether diol with a number average molecular weight of 2000 and 16.21g of polytetrahydrofuran ether glycol with a number average molecular weight of 2000 after vacuum dehydration at 110°C for 1.5h. Fill the ethylene adipate diol mixed solution with dry nitrogen for protection, raise the temperature to 95°C, and keep it warm for 120 minutes to obtain the isocyanate-terminated polysulfide-modified polyurethane prepolymer;

[0060] S2. Cool the isocyanate-terminated polysulfide-modified polyurethane prepolymer to 40°C, then add 10.2g of ethylene glycol, 0.65g of triethanolamine, 0.07g of stannous octoate, 0.08g of dibutyltin dilaurate and 25mL of acetone, Raise the temperature to 80°C, keep it warm for 120min, cool down to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com