Uniform-grain-size agarose gel microsphere production system and production process thereof

A technology of agarose gel microspheres and agarose gel, which is applied in the field of agarose gel microsphere production system, can solve the problems of different particle sizes, wide distribution coefficients, poor microsphere formation rate, etc., and achieve The effect of intelligent continuous production, realizing recycling and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

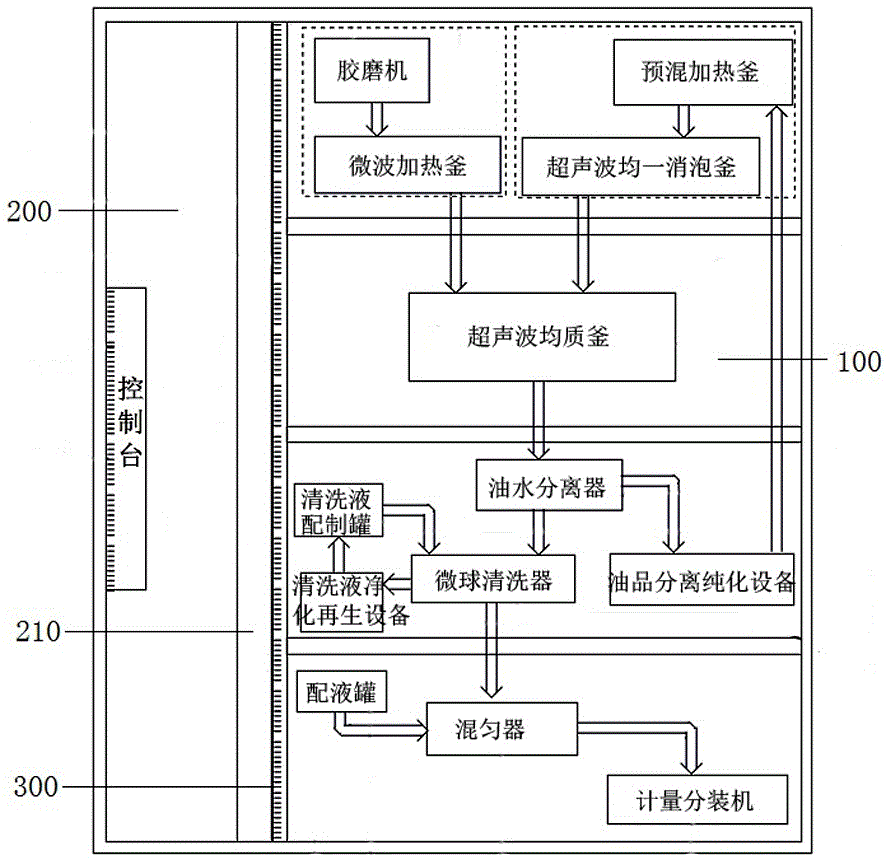

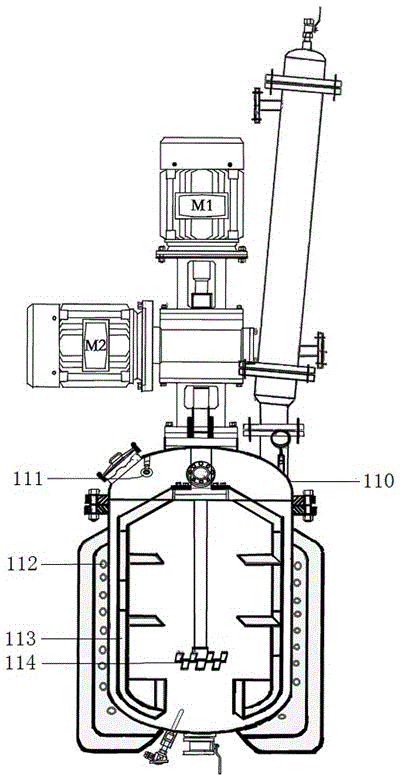

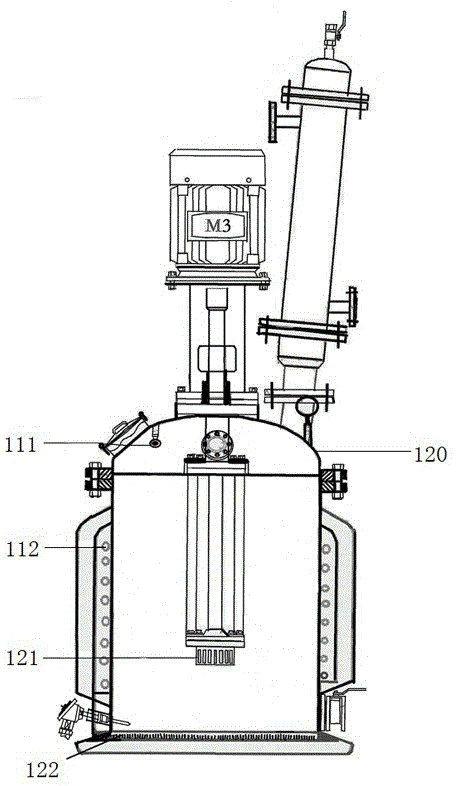

[0028] Example 1: Such as Figure 1~4 Shown, a kind of agarose gel microsphere production system with uniform particle diameter comprises production area 100 and the control area 200 that is positioned at the side of production area, rubber mill and premix heating still are arranged in described production area 100, The premix heating kettle is a premix kettle with heating function, the rubber mill is connected with a microwave heating kettle 110, the premix heating kettle is connected with an ultrasonic uniform defoaming kettle 120, and the microwave The heating kettle 110 and the ultrasonic uniform defoaming kettle 120 are all connected with an ultrasonic homogenizing kettle 130, the high-frequency ultrasonic homogenizing kettle is connected with an oil-water separator, and the water phase outlet of the oil-water separator is connected with a microsphere The cleaner is connected, and the microsphere cleaner is connected with a mixer, and the mixer is connected with a meter...

Embodiment 2

[0042] Example 2: A high-efficiency production process of agarose gel microspheres with uniform particle size, comprising the production system of agarose gel microspheres with uniform particle size as described in Example 1, and carried out according to the following steps: (1) agarose is pressed A certain ratio is added to ultrapure water, and transported to a rubber mill for 10 minutes, and then transported to a microwave heating kettle to quickly and fully dissolve to form glue A; at the same time, light oil as a solvent and heavy oil as a surfactant Add it into the pre-mixed heating tank at a certain ratio, mix and heat it, and then transport it to the ultrasonic uniform defoaming tank for treatment to form a uniform non-foaming thermal oil phase B; (2) Transport the uniform non-foaming thermal oil phase B to the ultrasonic homogenizing tank Heat to 200°C, turn on the high-frequency ultrasonic generator and start the side stirring paddle and the emulsification head, the ...

Embodiment 3

[0048] Example 3: A high-efficiency production process of agarose gel microspheres with uniform particle size, comprising the production system of agarose gel microspheres with uniform particle size as described in Example 1, and carried out according to the following steps: (1) agarose is pressed A certain ratio is added to ultrapure water, and transported to a rubber mill for 20 minutes, and then transported to a microwave heating kettle to quickly and fully dissolve to form glue A; at the same time, light oil as a solvent and heavy oil as a surfactant Add it into the pre-mixed heating tank at a certain ratio, mix and heat it, and then transport it to the ultrasonic uniform defoaming tank for treatment to form a uniform non-foaming thermal oil phase B; (2) Transport the uniform non-foaming thermal oil phase B to the ultrasonic homogenizing tank Heat to 300°C, turn on the high-frequency ultrasonic generator and start the side stirring paddle and the emulsification head, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com