Solid grouting material and preparing method thereof

A solid grouting material, water glass technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., to achieve the effect of reducing production energy consumption, excellent performance, and low permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific embodiments. This implementation case is carried out on the premise of the technology of the present invention, and the detailed implementation and specific operation process are now given to illustrate the inventiveness of the present invention, but the protection scope of the present invention is not limited to the following examples.

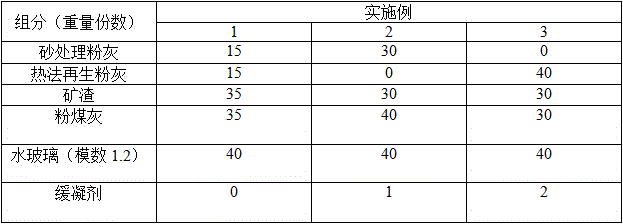

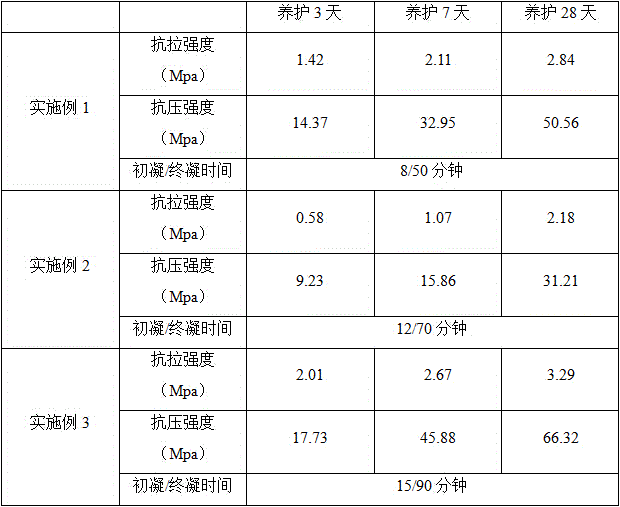

[0025] A solid grouting material, comprising the following components by weight: 30-40 parts of casting fly ash, 30-40 parts of slag, 30-40 parts of fly ash and 40-42 parts of water glass; wherein, the casting fly ash It includes one or both of sand treatment fly ash and thermal regeneration dust. The solid grouting material component may also include a setting retarder≤2 parts, and the setting retarder may be selected from sodium dihydrogen phosphate.

[0026] In the above-mentioned solid grouting material, the modulus of the water glass can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com