A method for preparing graphene microsheets using a pulsed high-pressure water jet pulverizer

A graphene microchip and water jet pulverization technology, which is applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of large environmental pollution, high production cost of graphene, complicated preparation process, etc., and the preparation method is easy , low cost, evenly dispersed layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

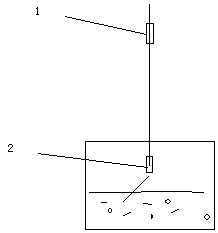

Image

Examples

Embodiment 1

[0028] A kind of method utilizing pulse high-pressure water jet pulverizer to prepare graphene microchip:

[0029] (1) 90 parts by weight of graphite powder was heated and pretreated at a heating temperature of 180°C for 20 minutes, and then graphite powder, 0.5 parts by weight of ethanol, 0.4 parts by weight of potassium tripolyphosphate and 500 parts by weight of In the high-speed mixer that water is added, stir with rotating speed 360rpm simultaneously during adding process, stirring time 3min, obtain graphite powder aqueous solution;

[0030] (2) Send the graphite powder aqueous solution obtained in step (1) into a closed reaction kettle, pressurize and intercalate the graphite powder for 4 hours under a pressure of 10 MPa, and weaken the van der Waals force between graphite powder layers to obtain pretreated graphite powder aqueous solution;

[0031] (3) Send the pretreated graphite powder aqueous solution obtained in step (2) into the pulse high-pressure water jet pulve...

Embodiment 2

[0033] A kind of method utilizing pulse high-pressure water jet pulverizer to prepare graphene microchip:

[0034](1) 98 parts by weight of graphite powder were heated and pretreated at a heating temperature of 220°C for 40 minutes, and then graphite powder, 2.0 parts by weight of ethanol, 1.5 parts by weight of potassium tripolyphosphate and 1000 parts by weight of In the high-speed mixer that water is added, stir with rotating speed 480rpm simultaneously during adding process, stirring time 3min, obtain graphite powder aqueous solution;

[0035] (2) Send the graphite powder aqueous solution obtained in step (1) into a closed reaction kettle, pressurize and intercalate the graphite powder for 10 hours under a pressure of 25 MPa to weaken the van der Waals force between graphite powder layers, and obtain pretreated graphite powder aqueous solution;

[0036] (3) Send the pretreated graphite powder aqueous solution obtained in step (2) into the pulse high-pressure water jet pul...

Embodiment 3

[0038] A kind of method utilizing pulse high-pressure water jet pulverizer to prepare graphene microchip:

[0039] (1) 93 parts by weight of graphite powder were heated and pretreated at a heating temperature of 200°C for 30 minutes, and then graphite powder, 1.6 parts by weight of ethanol, 1.1 parts by weight of potassium tripolyphosphate and 8000 parts by weight of In the high-speed mixer that water is added, stir with rotating speed 400rpm simultaneously during adding process, stirring time 3min, obtain graphite powder aqueous solution;

[0040] (2) Send the graphite powder aqueous solution obtained in step (1) into a closed reaction kettle, pressurize and intercalate the graphite powder for 6 hours under a pressure of 16 MPa to weaken the van der Waals force between graphite powder layers, and obtain pretreated graphite powder aqueous solution;

[0041] (3) Send the pretreated graphite powder aqueous solution obtained in step (2) into the pulse high-pressure water jet pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com