A high-efficiency ball mill with reinforcing ribs

A rib and ball mill technology, applied in the field of ceramic machinery, can solve the problems of increased grinding time, small interlayer space, inconvenient installation and replacement of liners, etc., and achieve the effect of increasing grinding efficiency and shortening grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

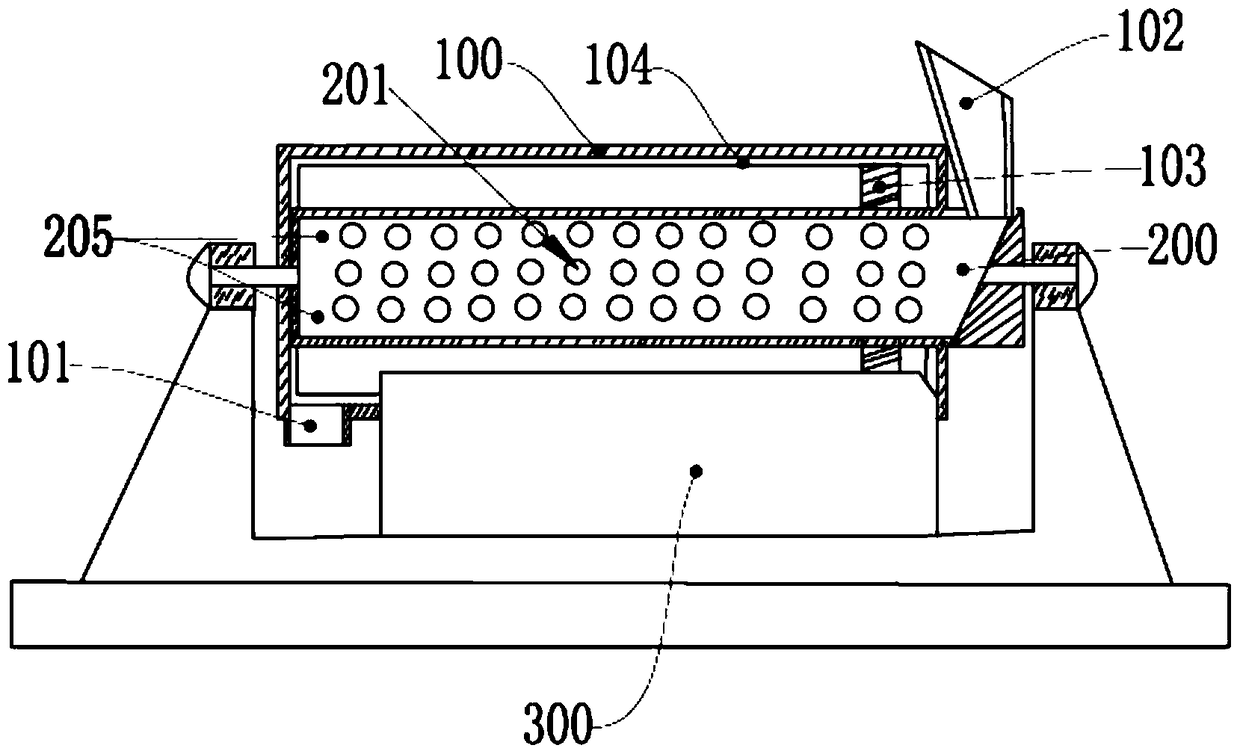

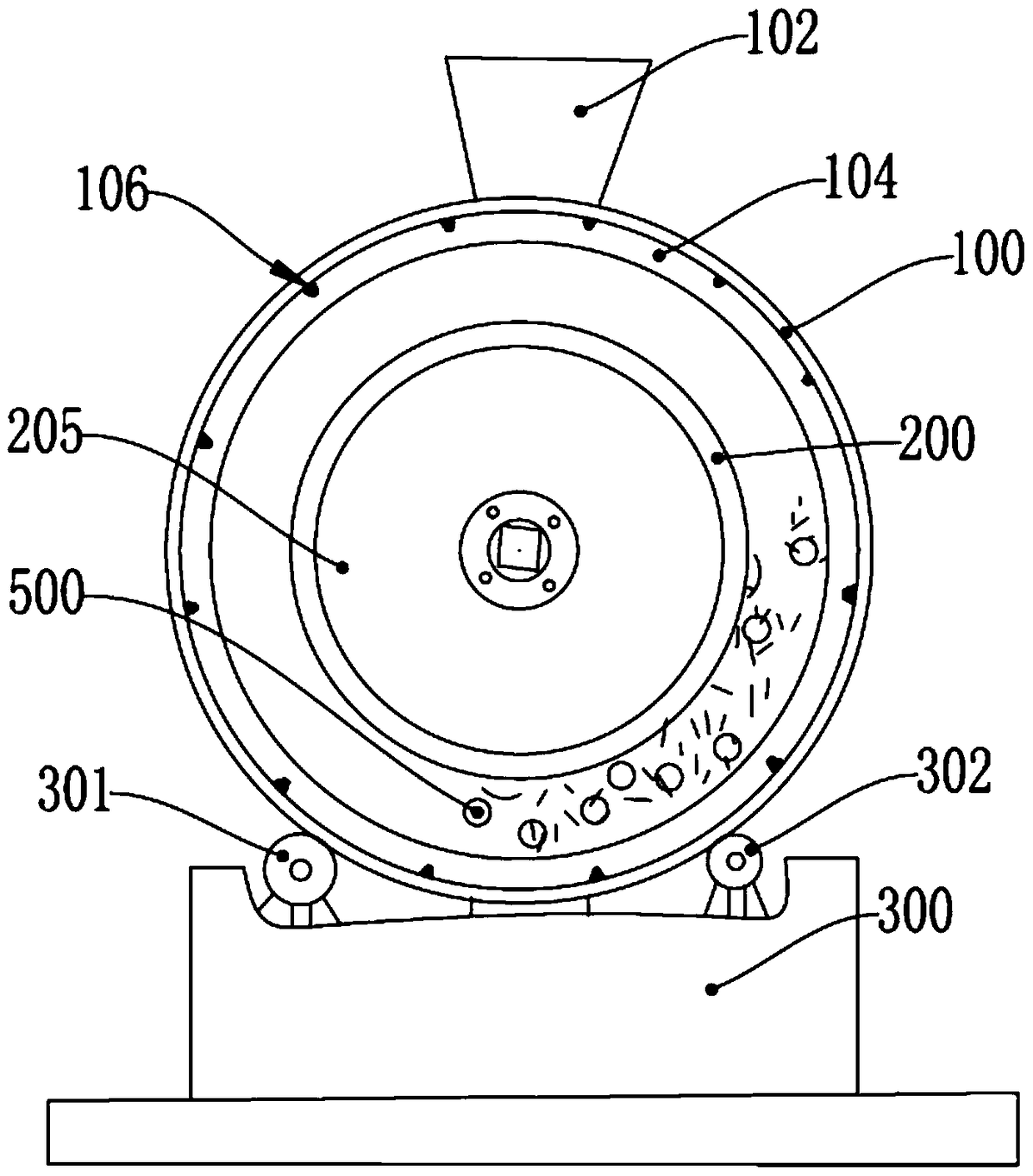

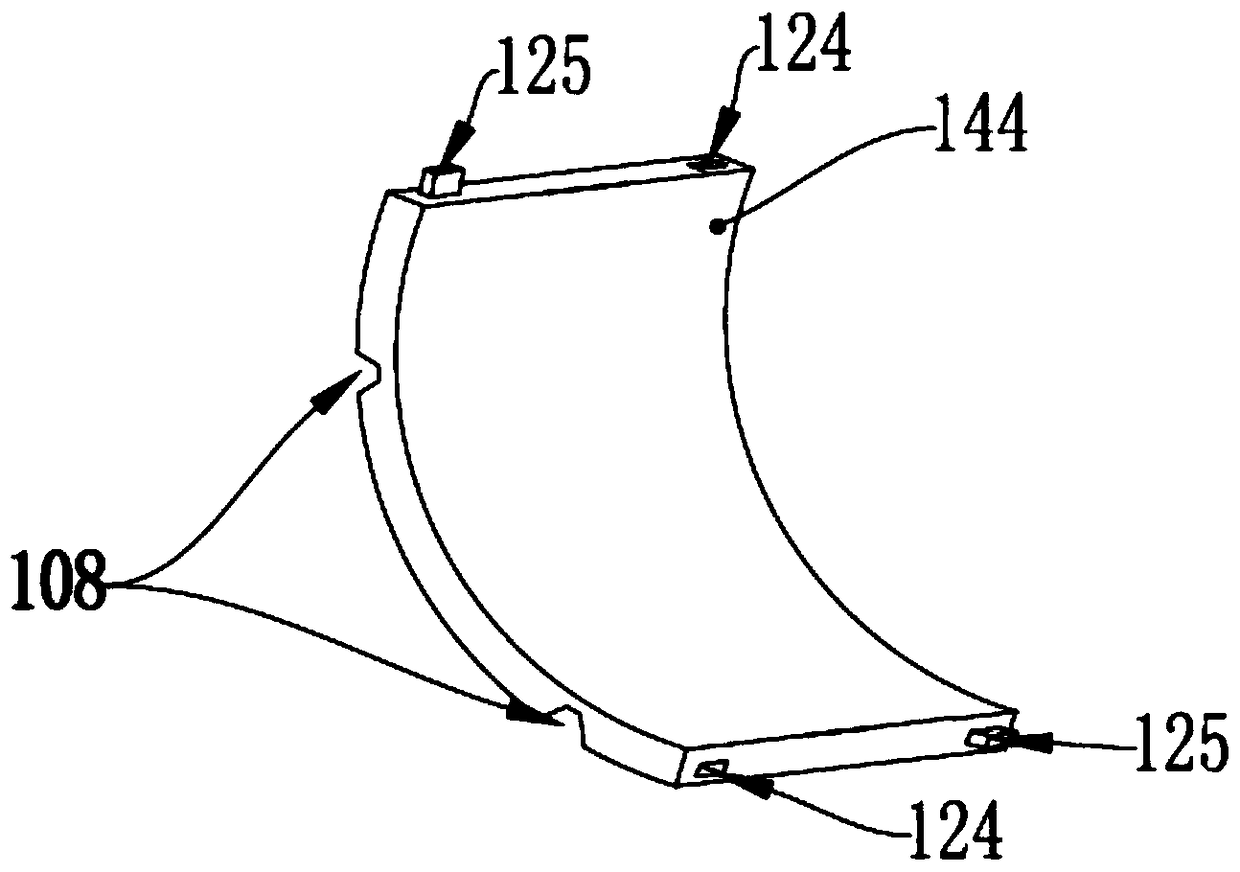

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] like Figure 1-3 As shown, a high-efficiency ball mill with reinforcing ribs includes a cylinder body 100 provided with a feed inlet 102 and a discharge outlet 101 and a drive device 300, and the drive device 300 drives the cylinder body 100 to rotate, and the cylinder body 100 is divided into two layers of tubular structure, the first layer is the cylinder shell, the second layer is the primary sieve grinding network pipe 200 with sieve holes, which is made of non-magnetic copper alloy material, the cylinder 100 has a two-layer structure, Grinding balls are placed in the two-layer structure of the cylinder body 100, the grinding balls are magnetic steel balls 500, the feeding port 102 is connected with the cavity of the primary screening grinding network pipe 200, and the discharging port I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com