Platinum/silver alloy nano-particle catalyst, method for preparing same and application of platinum/silver alloy nano-particle catalyst

A nanoparticle and silver alloy technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of easy aggregation of platinum nanoparticles, cyclicity, and non-precious metal performance Poor, limited crustal reserves and other problems, to achieve excellent electrochemical catalytic performance, simple and easy preparation method, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of platinum / silver alloy nano particle catalyst, described preparation method comprises the following steps:

[0030] Add 80uL of 0.01M chloroplatinic acid aqueous solution to 10mL of 0.1MCTAB aqueous solution, shake well, then add 600μL of 0.01M sodium borohydride ice water solution, shake well, and let it stand for 3 hours to obtain a seed solution;

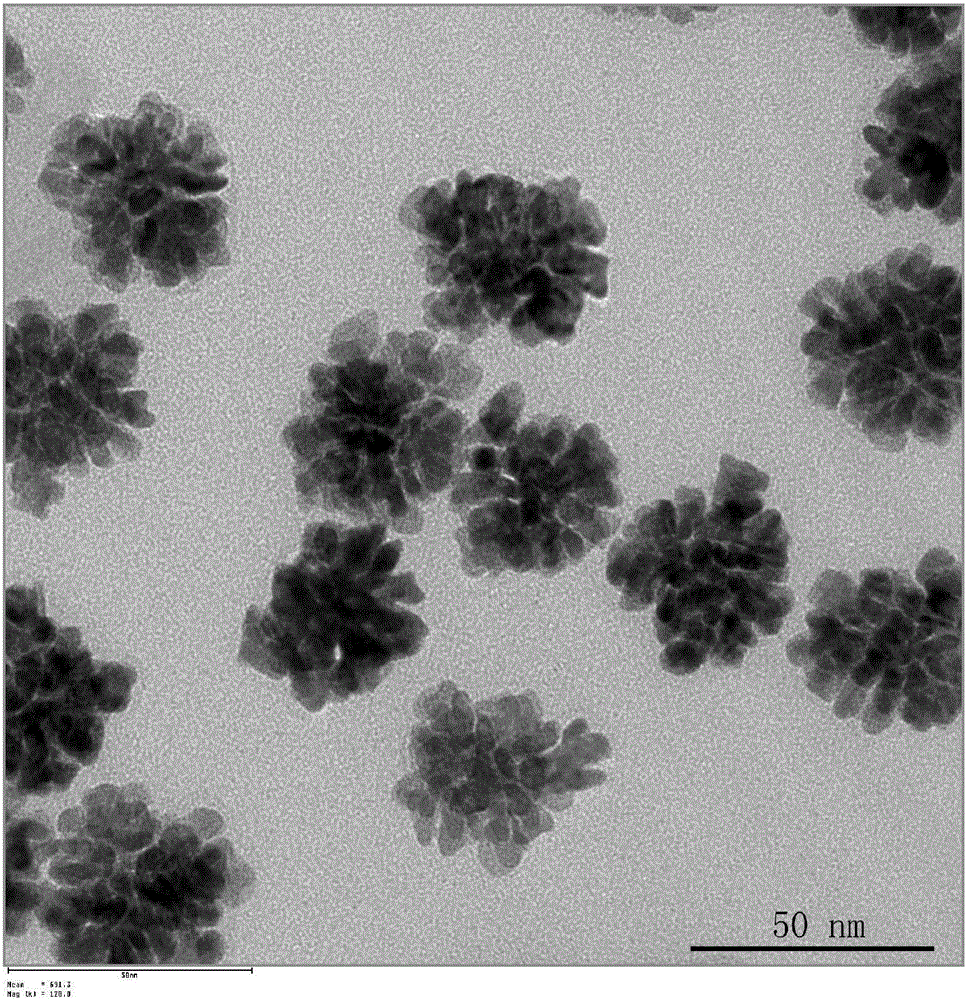

[0031] Add 660 μL of 0.01M chloroplatinic acid aqueous solution, 40 μL of 0.01M silver nitrate aqueous solution, 400 μL of 1M hydrochloric acid solution, 320 μL of 0.1M ascorbic acid aqueous solution, and 200 μL of the seed solution prepared in step 1 to 40 ml of 0.1MCTAB aqueous solution. The platinum / silver alloy nano particle catalyst can be prepared by standing in a constant temperature oven at ℃ for 80 hours. It is 24% to measure the molar percentage composition of silver in the product by inductively coupled plasma atomic emission spectrometry (ICP-AES), measure its XRD spectrogram and ...

Embodiment 2

[0033] A kind of preparation method of platinum / silver alloy nano particle catalyst, described preparation method comprises the following steps:

[0034] Add 80uL of 0.01M chloroplatinic acid aqueous solution to 10mL of 0.1MCTAB aqueous solution, shake well, then add 600μL of 0.01M sodium borohydride ice water solution, shake well, and let it stand for 3 hours to obtain a seed solution;

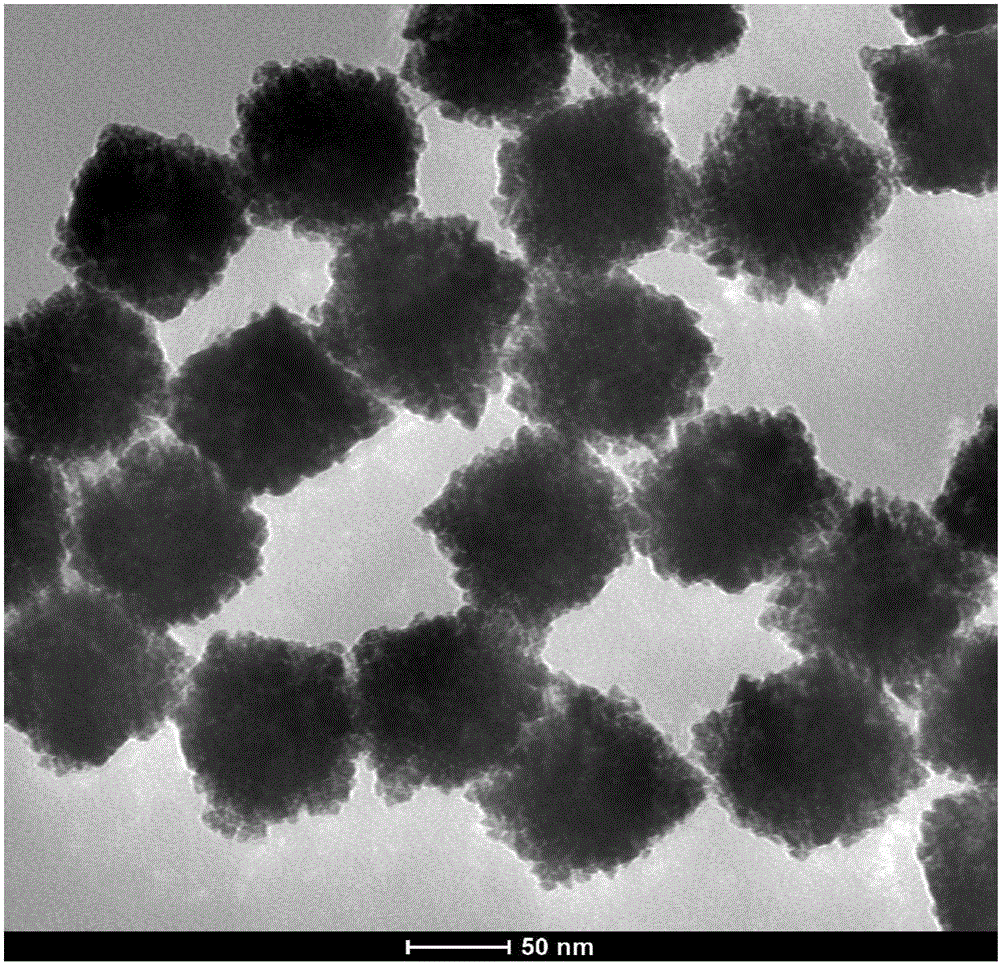

[0035] Add 660 μL of 0.01M chloroplatinic acid aqueous solution, 400 μL of 0.01M silver nitrate aqueous solution, 400 μL of 1M hydrochloric acid solution, 320 μL of 0.1M ascorbic acid aqueous solution, and 200 μL of the seed solution prepared in step 1 to 40 ml of 0.1MCTAB aqueous solution. The platinum / silver alloy nanoparticle catalyst can be prepared by standing in a constant temperature oven at ℃ for 72 hours. It is 30% to measure the molar percentage composition of silver in the product by inductively coupled plasma atomic emission spectrometry (ICP-AES), measure its XRD spectrogram and ...

Embodiment 3

[0037] A kind of preparation method of platinum / silver alloy nano particle catalyst, described preparation method comprises the following steps:

[0038] Add 80uL of 0.01M chloroplatinic acid aqueous solution to 10mL of 0.1MCTAB aqueous solution, shake well, then add 600μL of 0.01M sodium borohydride ice water solution, shake well, and let it stand for 3 hours to obtain a seed solution;

[0039]Add 660 μL of 0.01M chloroplatinic acid aqueous solution, 1000 μL of 0.01M silver nitrate aqueous solution, 400 μL of 1M hydrochloric acid solution, 320 μL of 0.1M ascorbic acid aqueous solution, and 200 μL of the seed solution prepared in step 1 to 40 ml of 0.1MCTAB aqueous solution. The platinum / silver alloy nano particle catalyst can be prepared by standing in a constant temperature oven at ℃ for 70 hours. It is 34% to measure the molar percentage composition of silver in the product by inductively coupled plasma atomic emission spectrometry (ICP-AES), measure its XRD spectrogram and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com