Preparing method of limited-range catalyst modified through atomic layer deposition and application thereof

An atomic layer deposition and catalyst technology, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of aminohydroxy compounds, etc., can solve the problems of limited interface sites between metals and oxide carriers, and achieves limited interface sites. Solve the effect of poor stability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

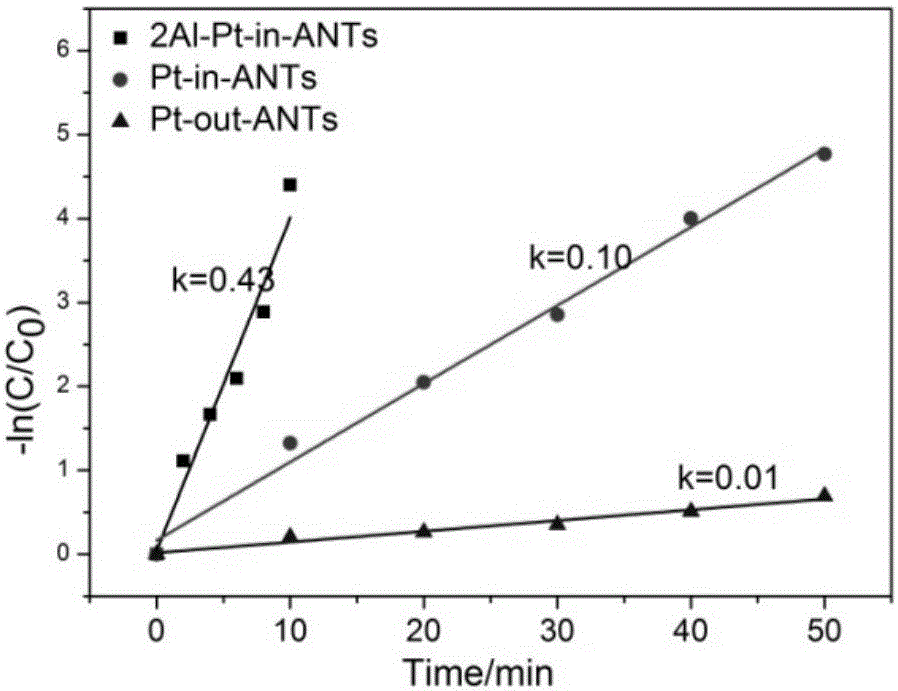

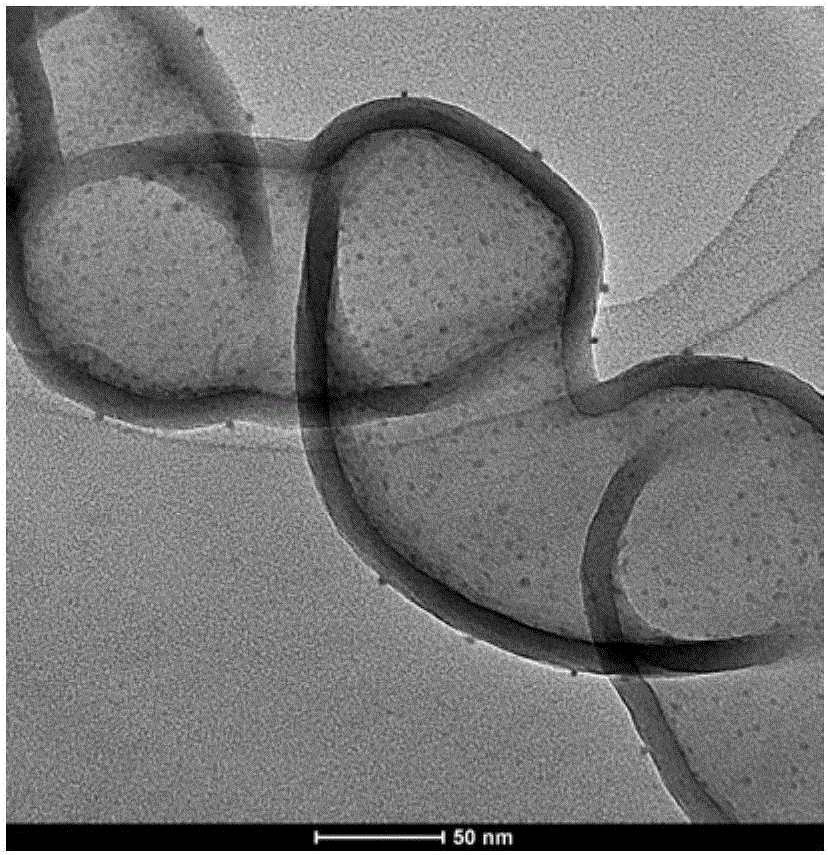

[0024] Example 1: Preparation of ultrathin modified confined Pt-based catalyst

[0025] (1) Preparation of carbon nanofibers as templates. The prepared dry carbon nanofibers were dissolved in ethanol, and the concentration was controlled at 0.05g / ml, and then the liquid was evenly coated on the surface of the glass sheet, evaporated to dryness and placed in the atomic layer deposition vacuum reaction chamber. When depositing alumina, the temperature of the chamber is controlled at 150°C, and the chamber pressure is 50Pa; when depositing Pt, the temperature of the chamber is controlled at 280°C, and the chamber pressure is 50Pa. During the deposition process, the volume of the wall is reacted with carrier gas and vacuum. The ratio is 1 / 8min -1 Fill the chamber with carrier gas. Deposition of Al using water and trimethylaluminum as precursors 2 o 3 . Pt nanoparticles were deposited using (trimethyl)methylcyclopentadiene platinum and ozone as precursors.

[0026] (2) Using ...

Embodiment 2

[0028] Example 2: Preparation of Ultrathin Modified Confined Catalysts

[0029] (1) Preparation of carbon nanofibers as templates. The prepared dry carbon nanofibers were dissolved in ethanol, and the concentration was controlled at 0.03g / ml, and then the liquid was evenly coated on the surface of the glass sheet, evaporated to dryness and placed in the atomic layer deposition vacuum reaction chamber. When depositing alumina, the temperature of the chamber is controlled at 180°C, and the chamber pressure is 60Pa; when depositing Pt, the temperature of the chamber is controlled at 300°C, and the chamber pressure is 60Pa. During the deposition process, the volume of the wall is reacted with carrier gas and vacuum. The ratio is 1 / 8min -1 Fill the chamber with carrier gas. Deposition of Al using water and trimethylaluminum as precursors 2 o 3 . Pt nanoparticles were deposited using (trimethyl)methylcyclopentadiene platinum and ozone as precursors.

[0030] (2) Using the carb...

Embodiment 3

[0032] Example 3: Preparation of Ultrathin Modified Confined Pt-Based Catalysts

[0033] (1) Preparation of carbon nanofibers as templates. The prepared dry carbon nanofibers were dissolved in ethanol, and the concentration was controlled at 0.01g / ml, and then the liquid was evenly coated on the surface of the glass sheet, evaporated to dryness, and then placed in the atomic layer deposition vacuum reaction chamber. When depositing alumina, the temperature of the chamber is controlled at 100°C, and the chamber pressure is 10Pa; when depositing Pt, the temperature of the chamber is controlled at 250°C, and the chamber pressure is 10Pa. During the deposition process, the volume of the wall is reacted with carrier gas and vacuum. The ratio is 1 / 10min -1 Fill the chamber with carrier gas. Deposition of Al using water and trimethylaluminum as precursors 2 o 3 . Pt nanoparticles were deposited using (trimethyl)methylcyclopentadiene platinum and ozone as precursors.

[0034] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com