Fumigation equipment and its smoke baffle, flue

A technology for smoke baffles and equipment, applied in the field of barbecue, can solve the problems of short flue gas flow path, unfoldable countertops, too much energy or fuel, etc., and achieves fuel-saving use, convenient storage and transportation, and good quality uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

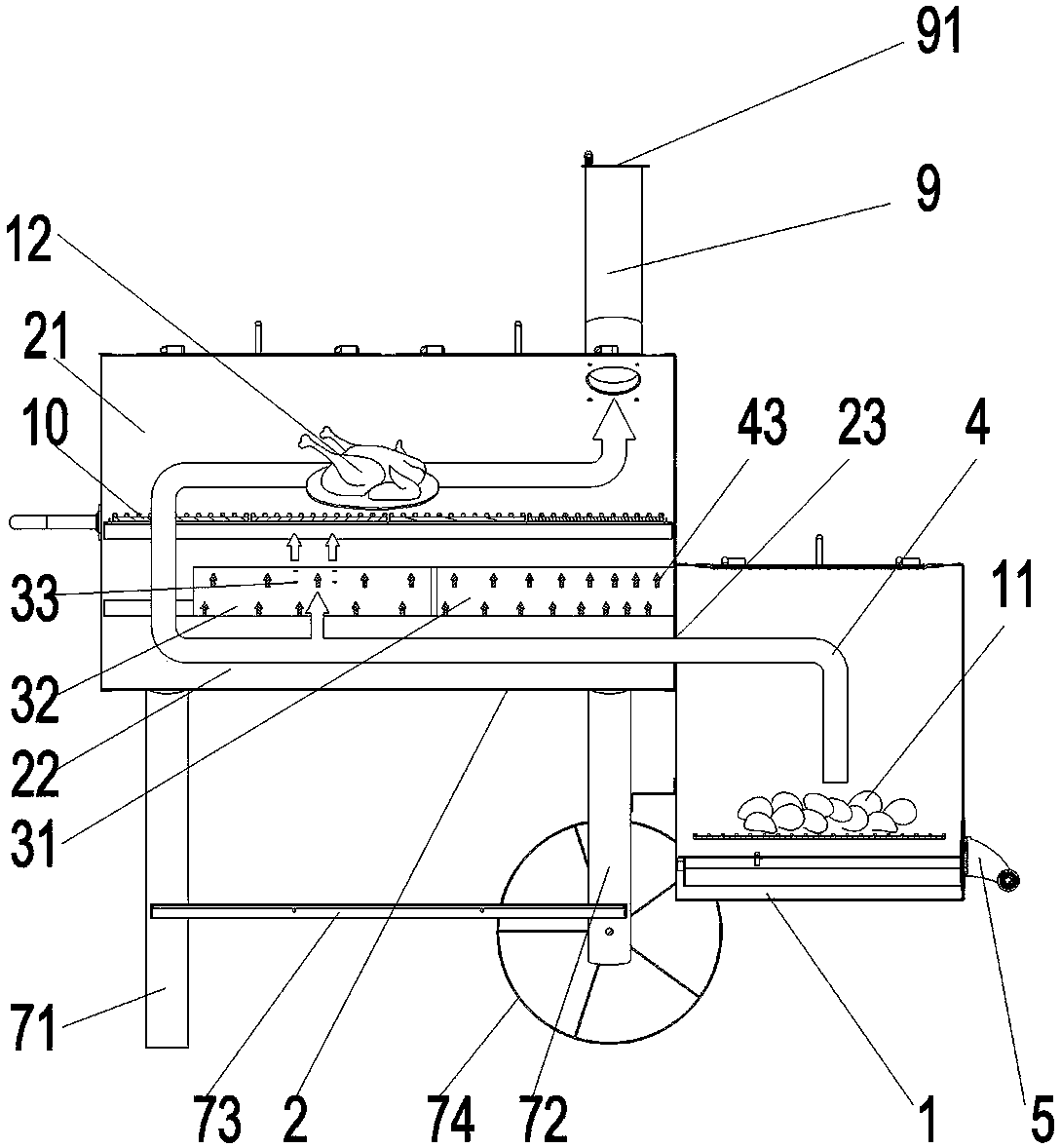

[0045] Such as Figure 2-Figure 6 As shown, a smoke baffle for smoking and roasting equipment, the smoking and roasting equipment includes a smoke and oven 2 and a flue gas generator 1 connected thereto, the smoke baffle is arranged in the smoke and oven 2 and separates the smoke and oven 2 Formed into an upper cavity 21 and a lower cavity 22, the smoke baffle includes a first smoke baffle 31 and a second smoke baffle 32 connected end to end; the first smoke baffle 31 is a non-porous plate; the second baffle The smoke plate 32 is provided with a plurality of smoke holes 33 . Both the first smoke baffle plate 31 and the second smoke baffle plate 32 are arc panels or curved panels. Positioning angle irons 34 are arranged above the two sides of the first smoke baffle plate 31 and the second smoke baffle plate 32 .

[0046] In the present invention, the arrangement of the curved plate and the curved plate, compared with the ordinary flat plate, the curved shape of the smoke baffle...

Embodiment 2

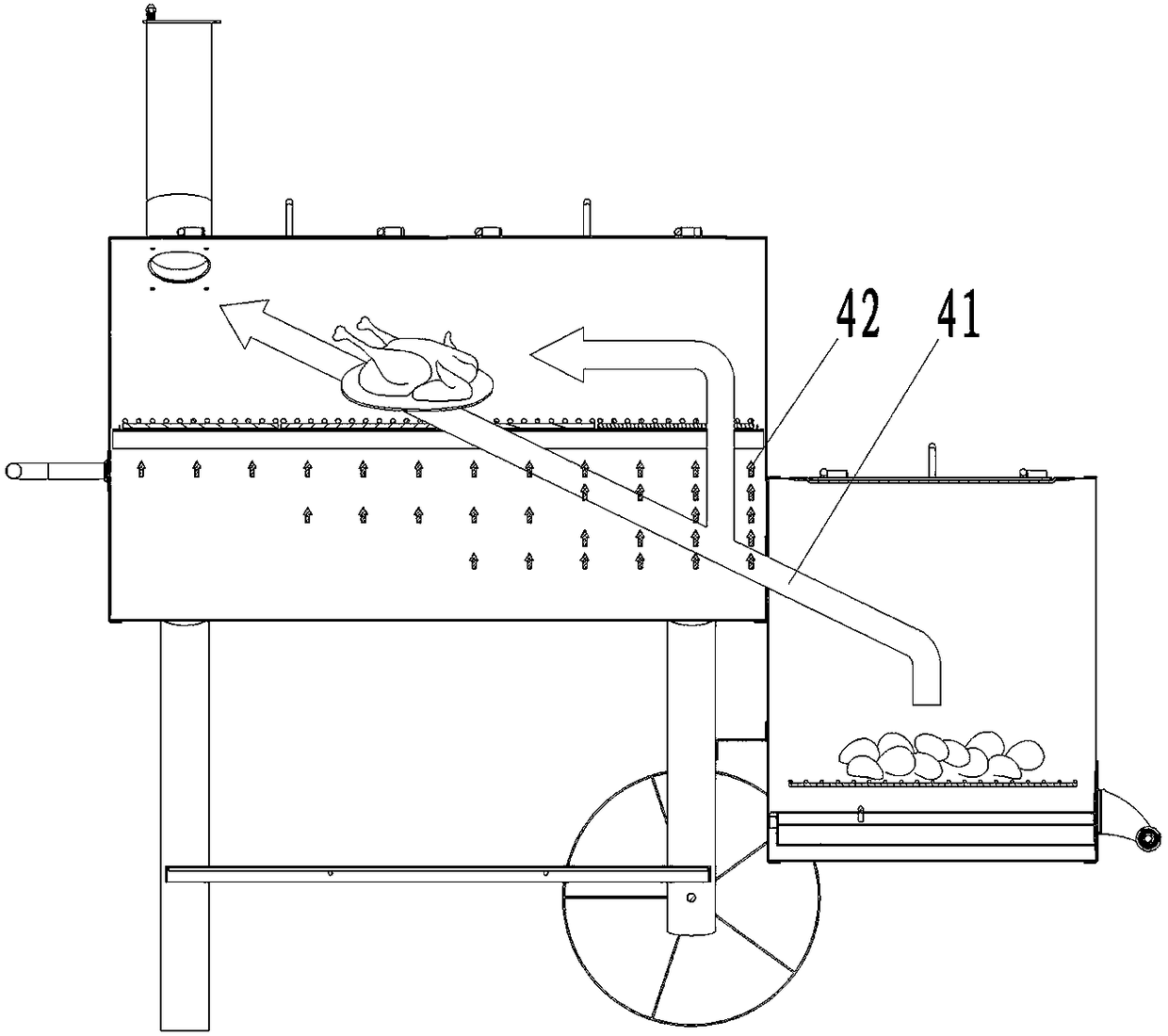

[0048] Such as Figure 2-Figure 6 As shown, in conjunction with Embodiment 1, a flue for smoking equipment, the flue includes an upper cavity 21, a lower cavity 22, and a smoke hole 33 separated by an upper smoke baffle; the flue gas 4 flows sequentially Through the lower cavity 22, the flue gas hole 33, and the upper cavity 21, the right end of the lower cavity 22 communicates with the top of the flue gas generator 1 through the flue gas inlet 23; the right end of the upper cavity 21 passes through the chimney 9 Connected with the atmosphere, the chimney 9 and the flue gas inlet 23 are set at the same end.

[0049] The present invention adopts the chimney 9 and the flue gas inlet 23 of the flue gas generator 1 to be located on the same side of the smoker 2, and adds a smoke baffle to double the flue gas circulation length, and the time for the flue gas to stay in the furnace body is also reduced. Doubled, not only to ensure the concentration of flue gas in the furnace body, ...

Embodiment 3

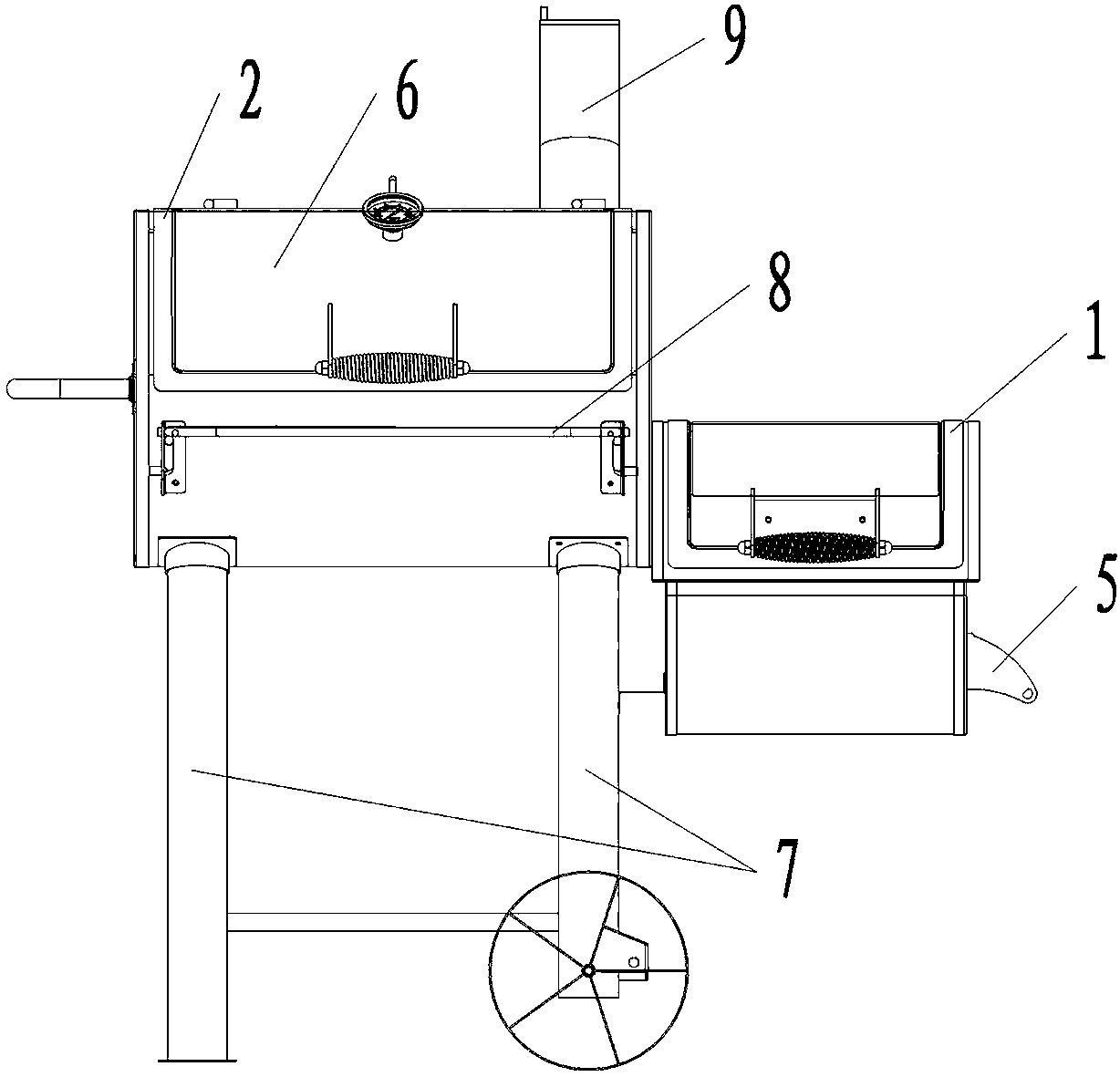

[0051] Such as Figure 2-Figure 10 As shown, in combination with Embodiment 1 and Embodiment 2, a kind of smoking equipment is provided. The smoke baffle as in Example 1 and the flue as in Example 2 are provided in the smoking oven of the smoking equipment; it also includes a folding table 8. Bench 7. Anti-drip cover door 6. Ash tray 5.

[0052] A smoked grill 10 for smoked food 12 is also provided above the top of the smoke baffle. Fuel 11 is provided in the flue gas generator 1, and the fuel is wood or charcoal.

[0053] The top of the chimney 9 is also provided with a flue gas regulating plate 91 which can be opened and closed by rotation. According to the different degrees of smoking, the speed of smoke and heat discharge can be adjusted through the smoke outlet adjustment plate 91, so as to speed up the efficiency of smoking. The smoking in the present invention refers to barbecue or smoking or barbecue smoking at the same time.

[0054] The bottom of the smoking oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com