Cabinet body

A cabinet and anti-compression layer technology, applied in the field of furniture, can solve the problems of limited application range, indoor air pollution, heavy cabinet quality, etc., to improve the strength and anti-compression ability, reduce the decoration process, overall strength and anti-corrosion The effect of increased pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0031] refer to figure 1 , The present invention provides a cabinet body, which is assembled from a plurality of side panels and door panels, and the side panels or / and door panels are all made of composite panels composed of multi-layer materials.

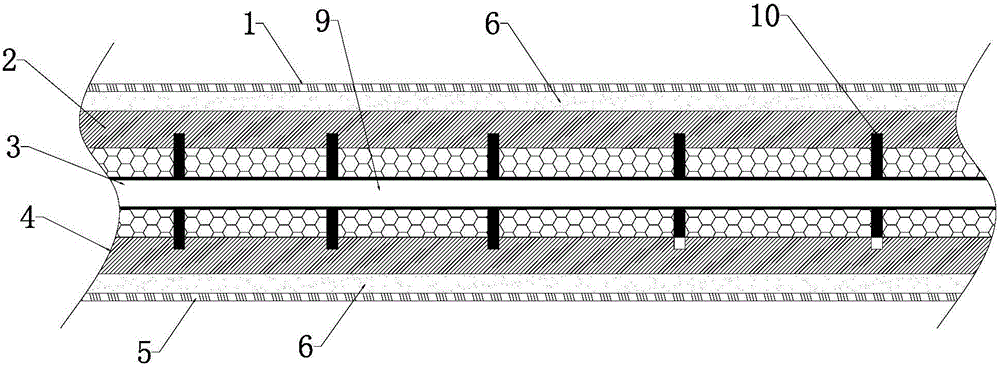

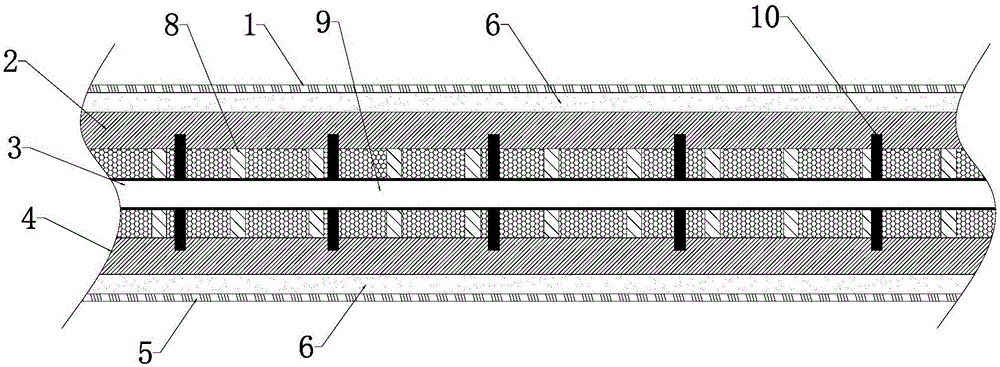

[0032] refer to figure 2 / 3 / 4 / 5 and 6, the composite panel includes an upper panel layer 1, an upper compression layer 2, an insulation layer 3, a lower compression layer 4 and a lower panel layer 5 from top to bottom, and the upper panel layer Adsorbent 6 is filled between 1 and the upper compression layer 2 or / and between the lower panel layer 5 and the lower compression layer 4, and the upper panel layer 1 or / and the lower panel layer 5 are densely covered with adsorbents communicating with the inner side of the absorbent layer. micropores, the adsorbent 6 adopts ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com