Grinding roller

A technology of grinding rollers and roller shafts, applied in the field of grinding rollers, can solve problems such as high wear and tear, and achieve the effect of improving cost and saving more costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

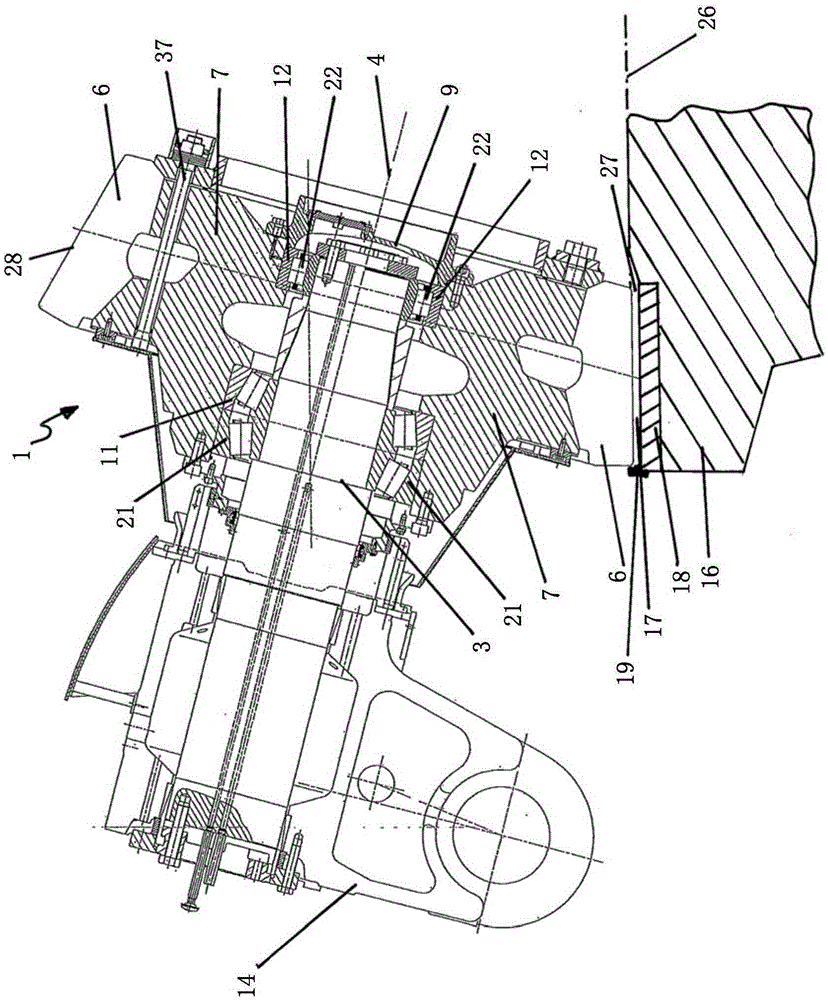

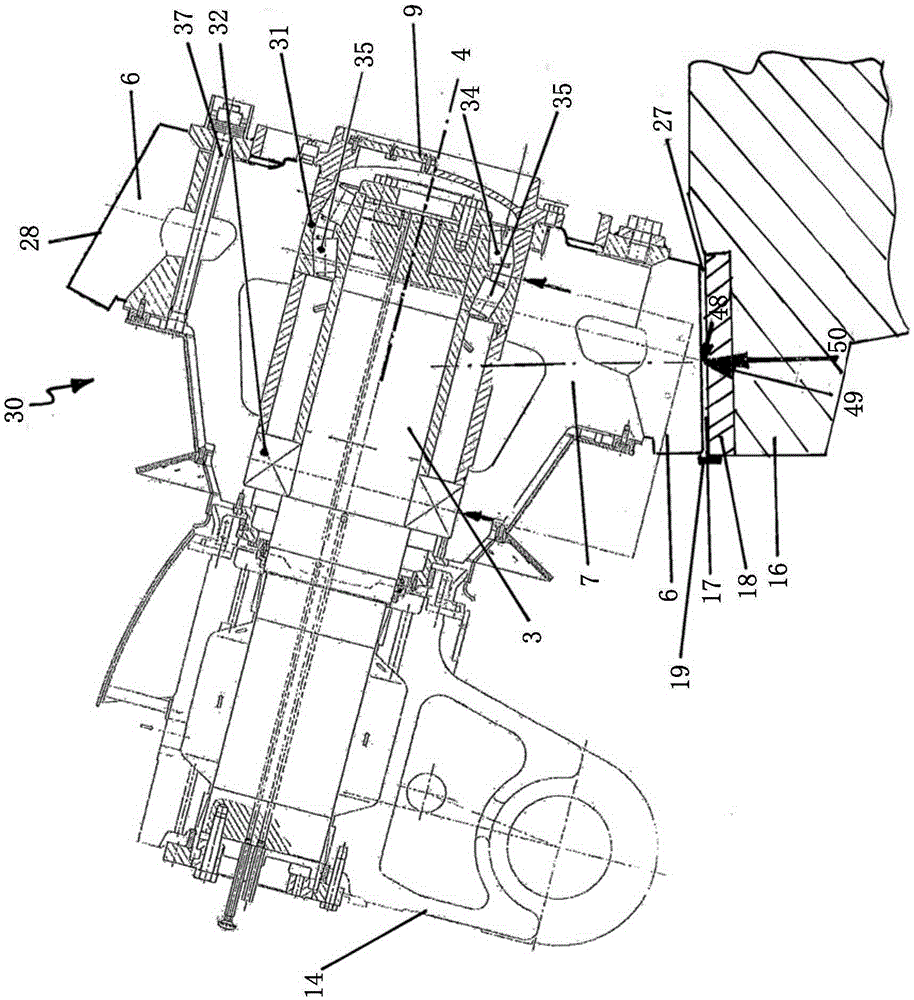

[0040] figure 1 A grinding roll 1 according to the invention is shown in axial section with a roll shaft 3 and a deflection by means of a rocker arm 14 . Considering the function of grinding and comminution of raw materials, the grinding table 16 with the grinding track plate 18, the rib 19 and the surface between the outer peripheral area of the roller sleeve 6 and the surface of the grinding track plate 18 are shown in fragments in the lower area. A part of the corresponding grinding gap 27 between them.

[0041] The outer peripheral region of the roller shell 6 and its slope 28 relative to the grinding roller axis 4 are designed such that the grinding gap 27 runs approximately parallel to the grinding table 26 .

[0042] It should be understood that in figure 1 and figure 2 In , the same reference numerals are used for the same or same type of components on the corresponding grinding roll.

[0043] The roller shaft 3 is rigidly and rotatably fixed firmly in the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com