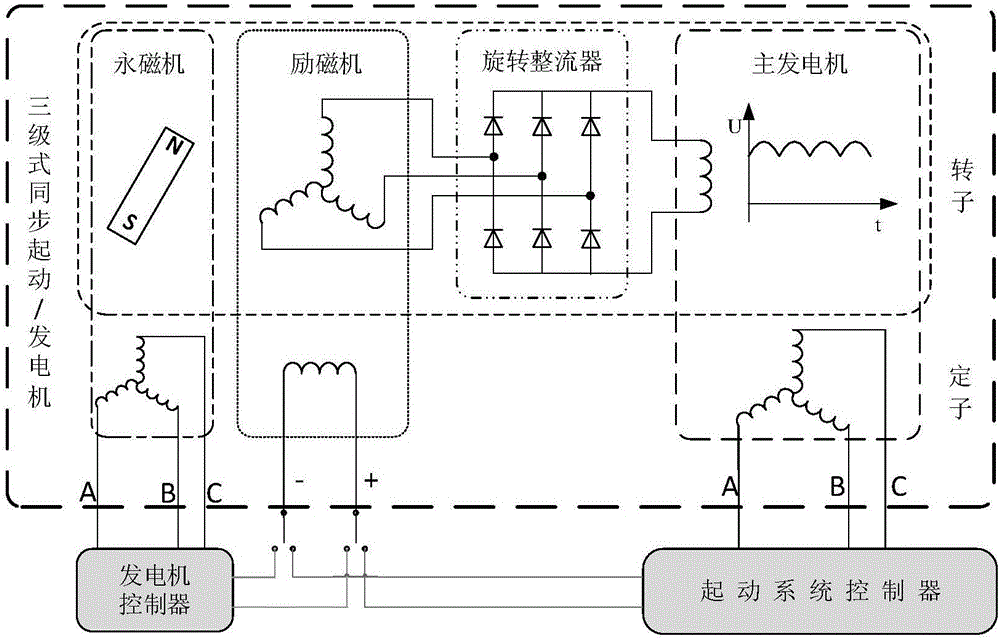

Three-level synchronous starter/generator starting control method based on current/rotate speed timesharing loop closing

A synchronous start and time-divided technology, which is applied in the direction of motor generator control, electronic commutation motor control, control generator, etc., can solve the problems of system start failure, motor torque impact, and motor dynamic start without consideration, and achieve Improve stability, reduce torque shock and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

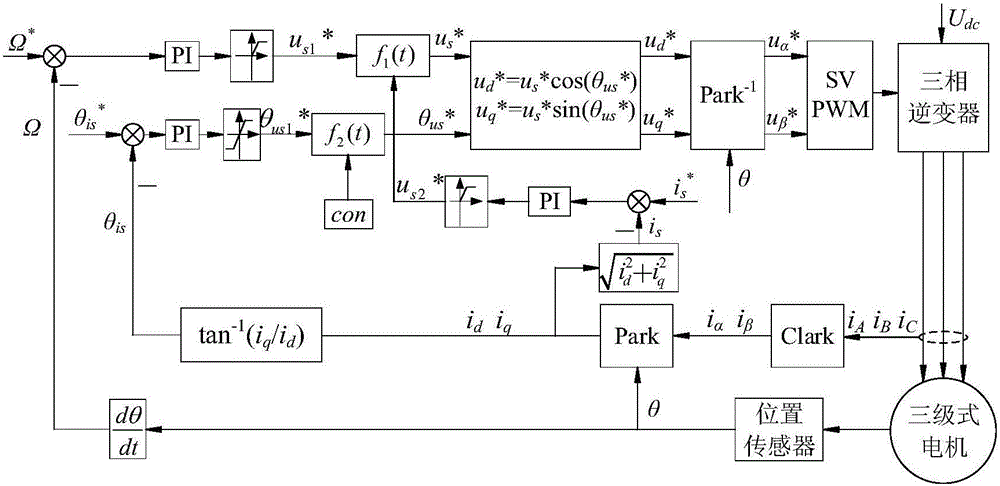

[0032] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0033] The 2PT115-T / 2PT115-P loading platform of MAGTROL Company was used to simulate the load of the aeroengine, and a three-stage synchronous starter / generator was used to build an experimental platform.

[0034] The concrete steps that embodiment comprises are as follows:

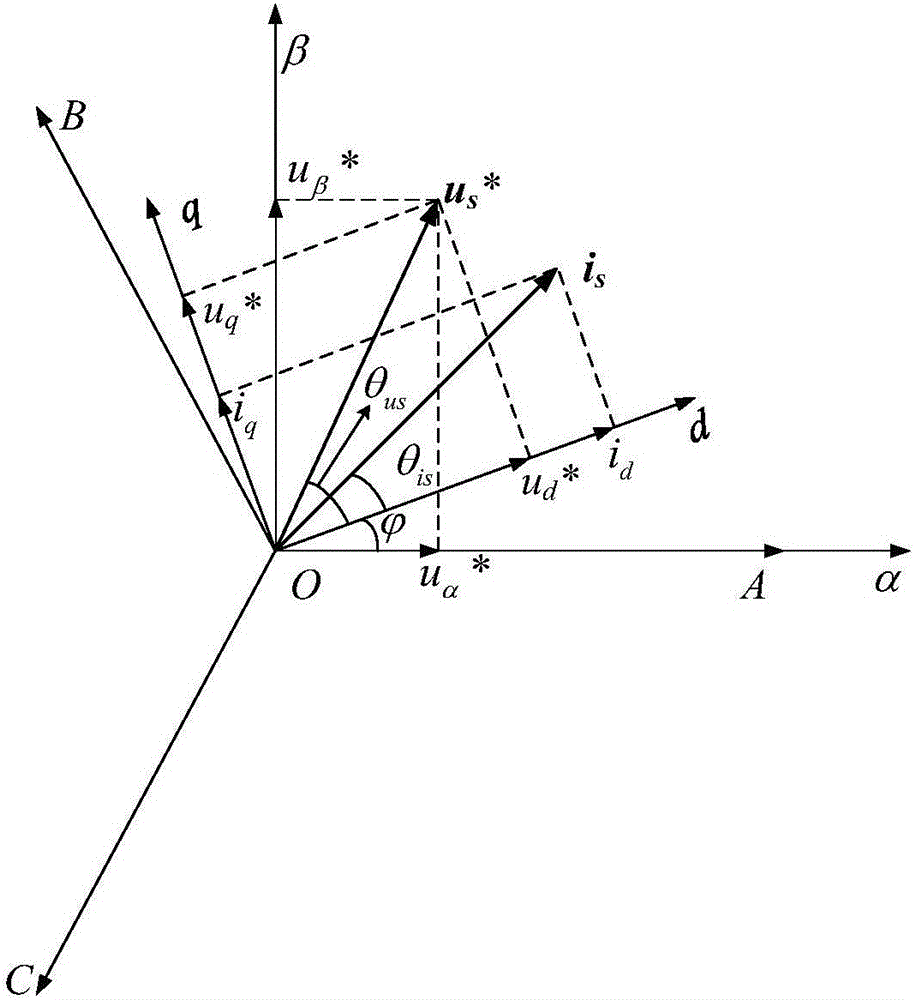

[0035] constructor f 1 (t), f 2 (t) as follows:

[0036]

[0037] The variables in the formula are defined as follows:

[0038] u s1 *Adjust the output voltage vector amplitude for the current closed loop;

[0039] u s2 *Adjust the output voltage vector amplitude for the speed closed loop;

[0040] θ us1 *Adjust the output voltage vector angle for the torque angle closed loop;

[0041] t is the running time of the system;

[0042] t 0 is the current loop action time;

[0043] t 1 is the action time of a given voltage vector angle.

[0044] Step 1: The motor is started stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com