Three-phase double-T five-level current transformer and control method therefor

A control method and five-level technology, applied in the direction of converting AC power input to DC power output, electrical components, and output power conversion devices, etc., can solve the problems of large volume, large control complexity, complex structure, etc. High reliability, easy expansion level, and high equivalent switching frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings.

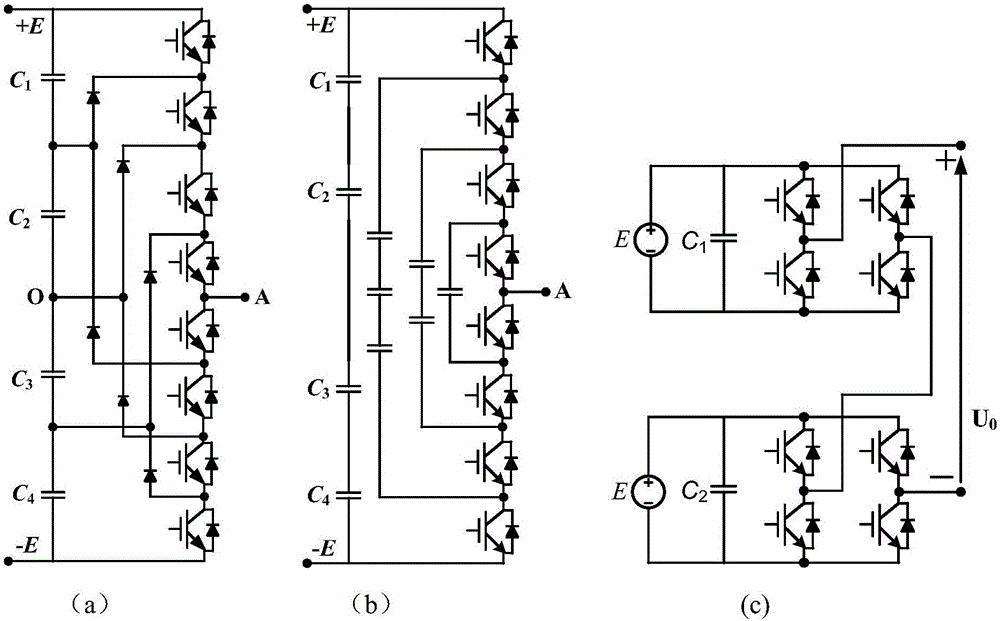

[0036] figure 1 (a), figure 1 (b) and figure 1 (c) shows the topology diagrams of three traditional five-level converters of diode clamp type, flying capacitor clamp type and cascaded H-bridge type respectively.

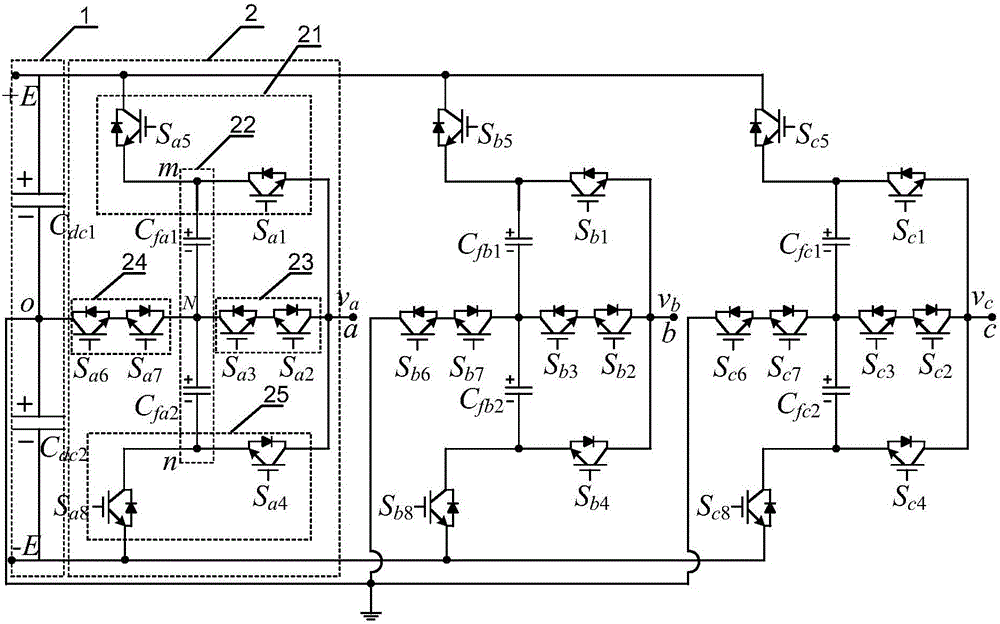

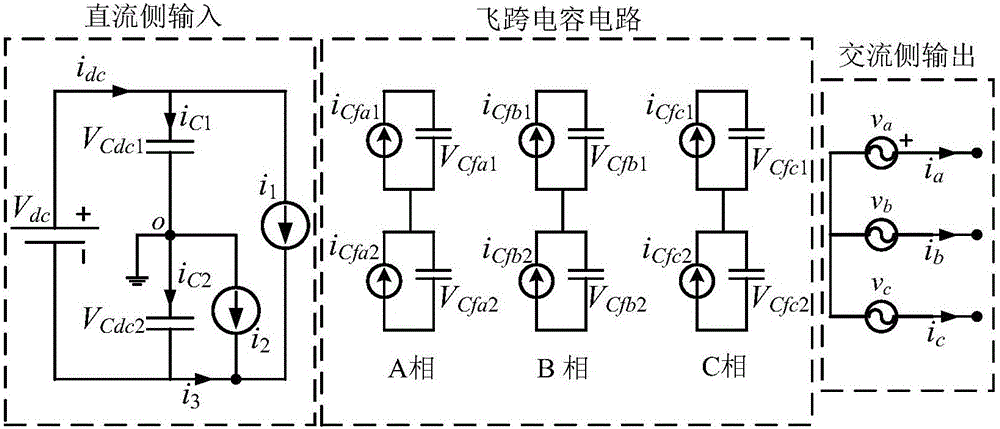

[0037] figure 2Shown is the topology of the three-phase double-T five-level converter proposed by the present invention. The converter is composed of three-phase double-T bridge arms and a DC bus 1 connected in parallel, wherein each phase bridge arm is composed of two three-voltage The flat-T converter topology is combined with two electrolytic capacitors connected in series. The three-phase double T-shaped bridge arms are respectively the A-phase bridge arm, the B-phase bridge arm and the C-phase bridge arm with the same circuit structure; Point clamping bridge arm 24, right middle point clamping bridge arm 23 and lower half bridge bridge arm 25;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com