Semiconductor device and manufacture method thereof

A device manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of complex process, high cost, large footprint, etc., to reduce process complexity and save process cost , Improving the effect of gate control capability and device density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

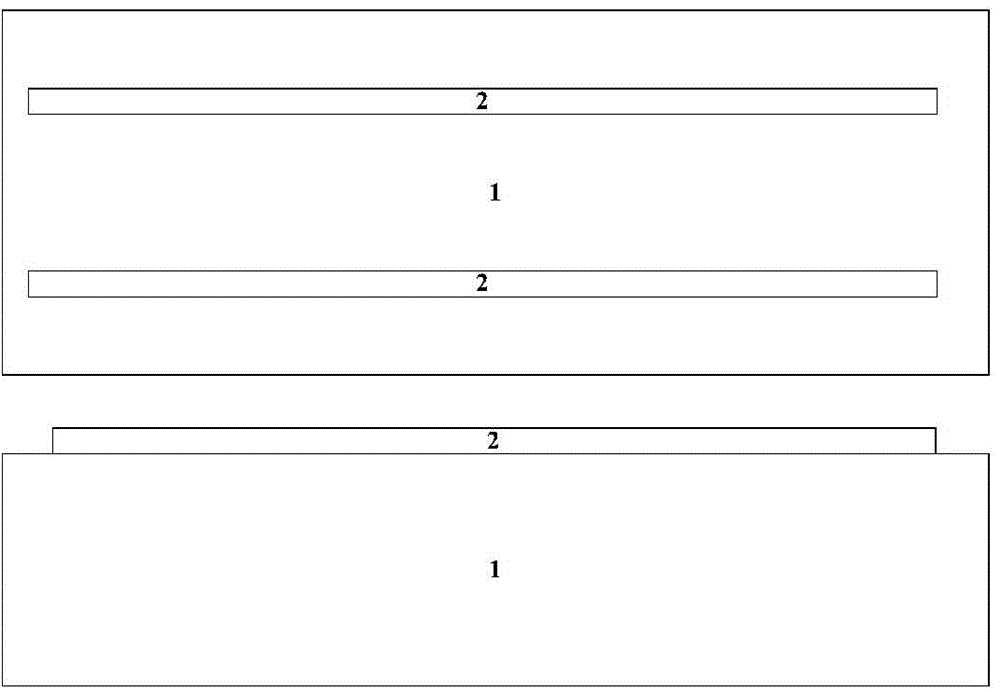

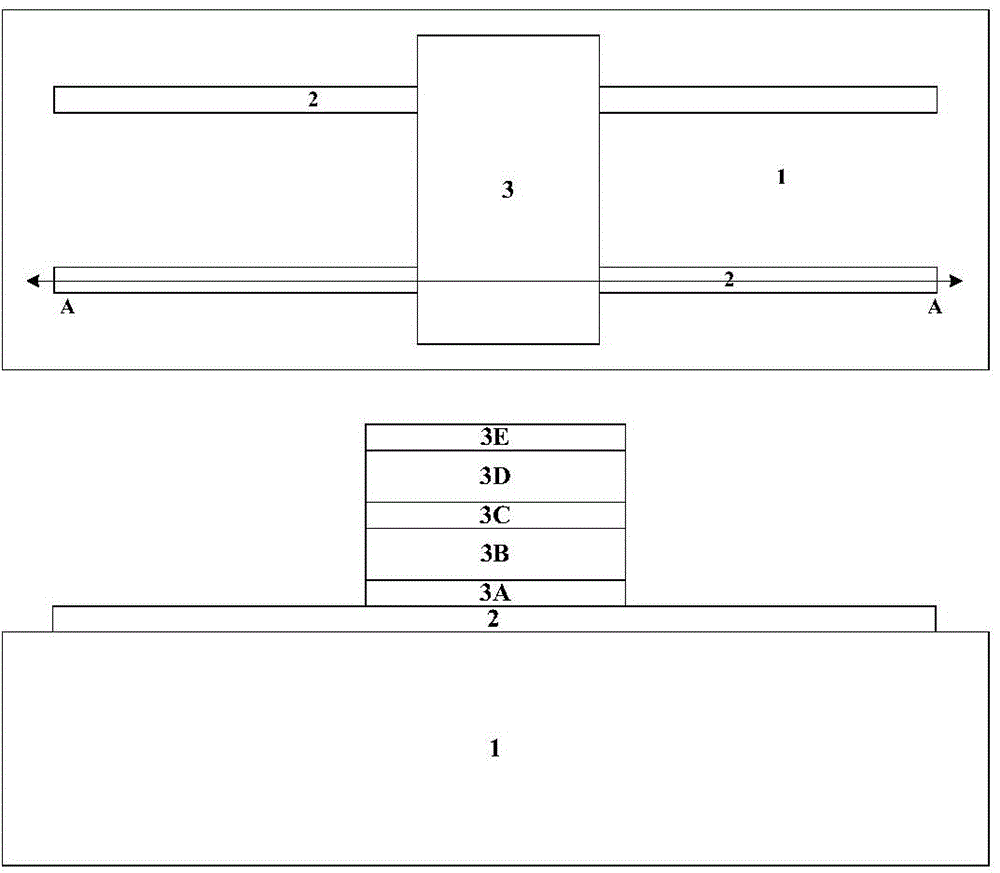

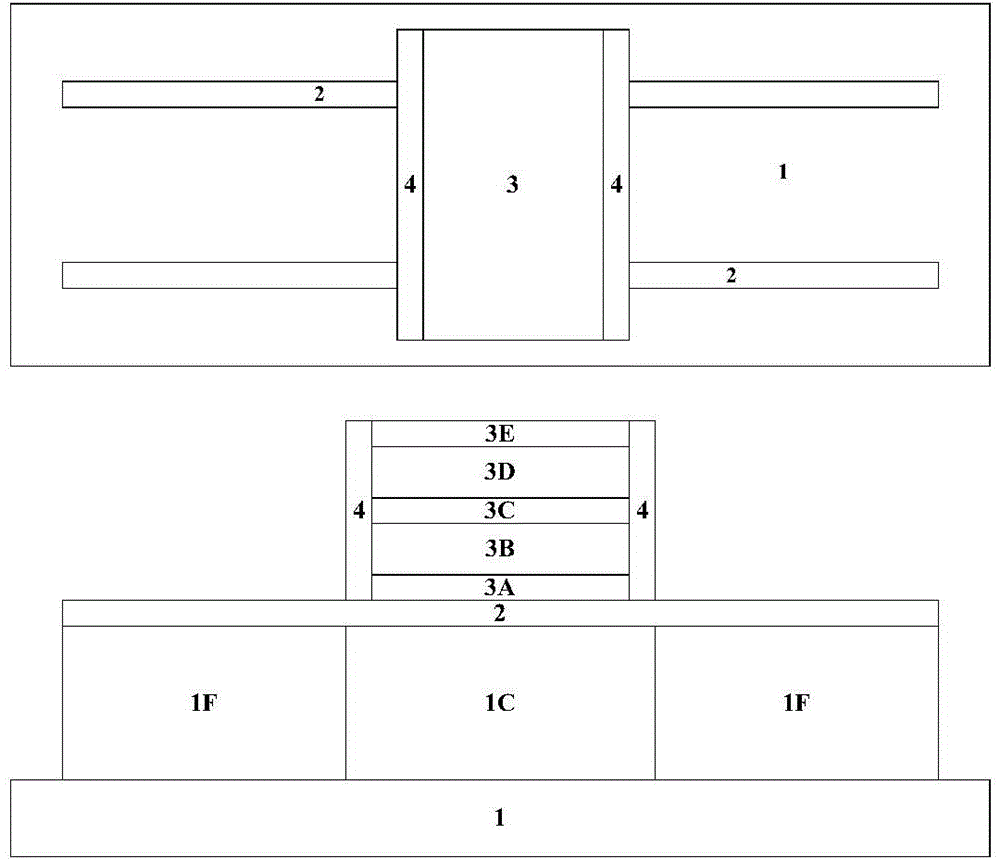

[0029] The features and technical effects of the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and in combination with schematic embodiments, disclosing a nanowire FinFET and its Manufacturing method. It should be pointed out that similar reference numerals represent similar structures, and the terms "first", "second", "upper", "lower", etc., etching, etc. used in this application can be used to modify various device structures or manufacturing process. These modifications do not imply spatial, sequential or hierarchical relationships of the modified device structures or fabrication processes unless specifically stated. In the following description, similar components are denoted by the same or similar reference numerals whether they are shown in different embodiments or not. In the various drawings, for the sake of clarity, various parts in the drawings are not drawn to scale.

[0030] In the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com