A kind of preparation method of nickel-palladium gold-plated bonding wire on copper-based surface

A bonding wire and nickel-plating technology, which is applied in superimposed layer plating, metal material coating process, semiconductor/solid-state device manufacturing, etc., to achieve strong bonding force, increase yield and production efficiency, and high bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

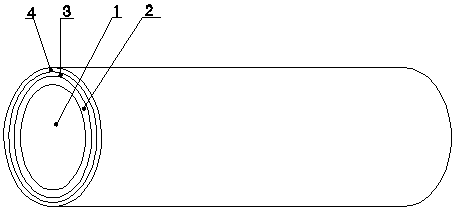

[0017] according to figure 1 As shown, the present invention relates to a nickel-palladium-gold-plated copper-based surface bonding wire, which includes a copper wire substrate 1, the outer surface of the copper wire substrate 1 is sequentially coated with a nickel-plated layer 2, a palladium-plated layer 3 and a gold-plated Layer 4, the thickness of the nickel-plated layer (2) of the nickel-plated palladium-gold bonding wire on the surface after plating is 0.05 μm-0.1 μm, the thickness of the palladium-plated layer (3) is 2 μm-4.0 μm, and the thickness of the gold-plated layer (4) 0.05 μm~0.1 μm; the copper wire substrate 1 plated with the nickel-plated layer 2, the palladium-plated layer 3 and the gold-plated layer 4 is stretched to form a nickel-palladium-gold bonding wire with a diameter of 15~50 μm on the surface; due to The bonding force between copper and nickel is very good. Since the nickel-plated palladium-gold bonding wire on the surface does not need to perform int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com