Double-color wheel synchronization control method and system for light source, and laser projection equipment

A synchronous control, dual-color wheel technology, applied in optics, instruments, projection devices, etc., can solve the problems of high assembly process difficulty and reduction of monochromatic brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

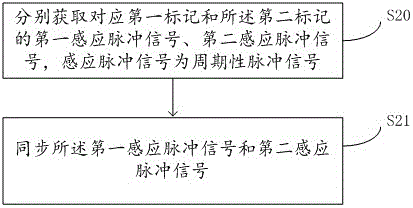

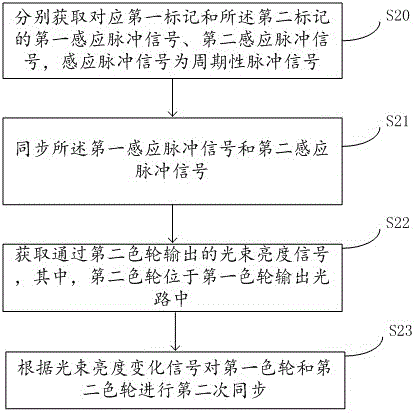

[0059] The embodiment of the present invention provides a method for synchronous control of two-color wheels of a light source, which is applied to the synchronous control of two-color wheels of non-coaxial design, such as Figure 2A shown, including:

[0060] S20: Obtain a first sensing pulse signal and a second sensing pulse signal corresponding to the first mark and the second mark respectively, where the sensing pulse signal is a periodic pulse signal;

[0061] Wherein, the first mark and the second mark are arranged on the positions corresponding to the first color wheel and the second color wheel respectively, and the first mark and the second mark follow the rotation of the color wheel to obtain the corresponding induction of the first mark and the second mark Pulse signal, the induction pulse signal is a periodic pulse signal, which is synchronized with the rotation period of the color wheel, and the above-mentioned first mark and second mark are the synchronization ma...

Embodiment 2

[0083] Embodiment 2 of the present invention is based on Embodiment 1 and described in detail in conjunction with the accompanying drawings.

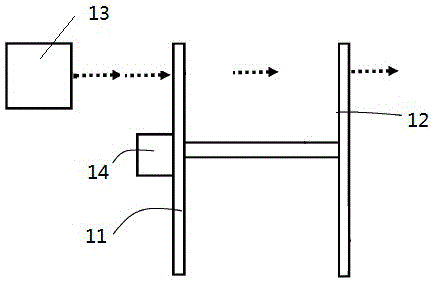

[0084] Specifically, Embodiment 3 of the present invention provides a two-color wheel synchronous control method for a light source, which is applied to a laser light source with a non-coaxial design of the two-color wheel. An example of the position and structure relationship of the non-coaxial two-color wheel can be shown in Figure 2 , the first color wheel 1 and the second color wheel 2 are respectively connected with drive motor shafts 12 and 22 to drive the wheel surface to perform periodic rotation, such as image 3 As shown, the extension lines of the centers of the drive motor shafts 12 and 22 intersect to form an angle, which can be an acute angle, a right angle or an obtuse angle, and in this example is a vertical relationship. That is to say, the rotation axes of the first color wheel 1 and the second color wheel 2 are not co...

Embodiment 3

[0116] The embodiment of the present invention also proposes a two-color wheel synchronous control system for the light source, such as Figure 11 As shown, a first color wheel 21 is included, and the first color wheel 21 includes a first mark (not shown in the figure); a second color wheel 22, and the second color wheel 22 includes a second mark (not shown in the figure), Where the first mark corresponds to the position of the second mark on the corresponding color wheel, the system further includes a first sensor 23 , a second sensor 24 , a third sensor 25 and a synchronous control unit 26 .

[0117] Wherein, the first sensor 23 is used to obtain the first sensing pulse signal of the first mark of the first color wheel, which is an infrared sensor or a light sensor; the second sensor 24 is used to obtain the first sensing pulse signal of the second mark of the second color wheel. The second induction pulse signal is an infrared sensor or a light sensor.

[0118] The synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com