Ash valve

A kind of ash and valve stem technology, applied in the direction of valve lift, valve details, valve device, etc., can solve problems such as daily maintenance and maintenance troubles, combustion can not continue normally, boiler slag volume is difficult to control, etc., to facilitate maintenance operations , the transmission mechanism is intuitive and clear, the effect of strengthening the strength and the ability of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

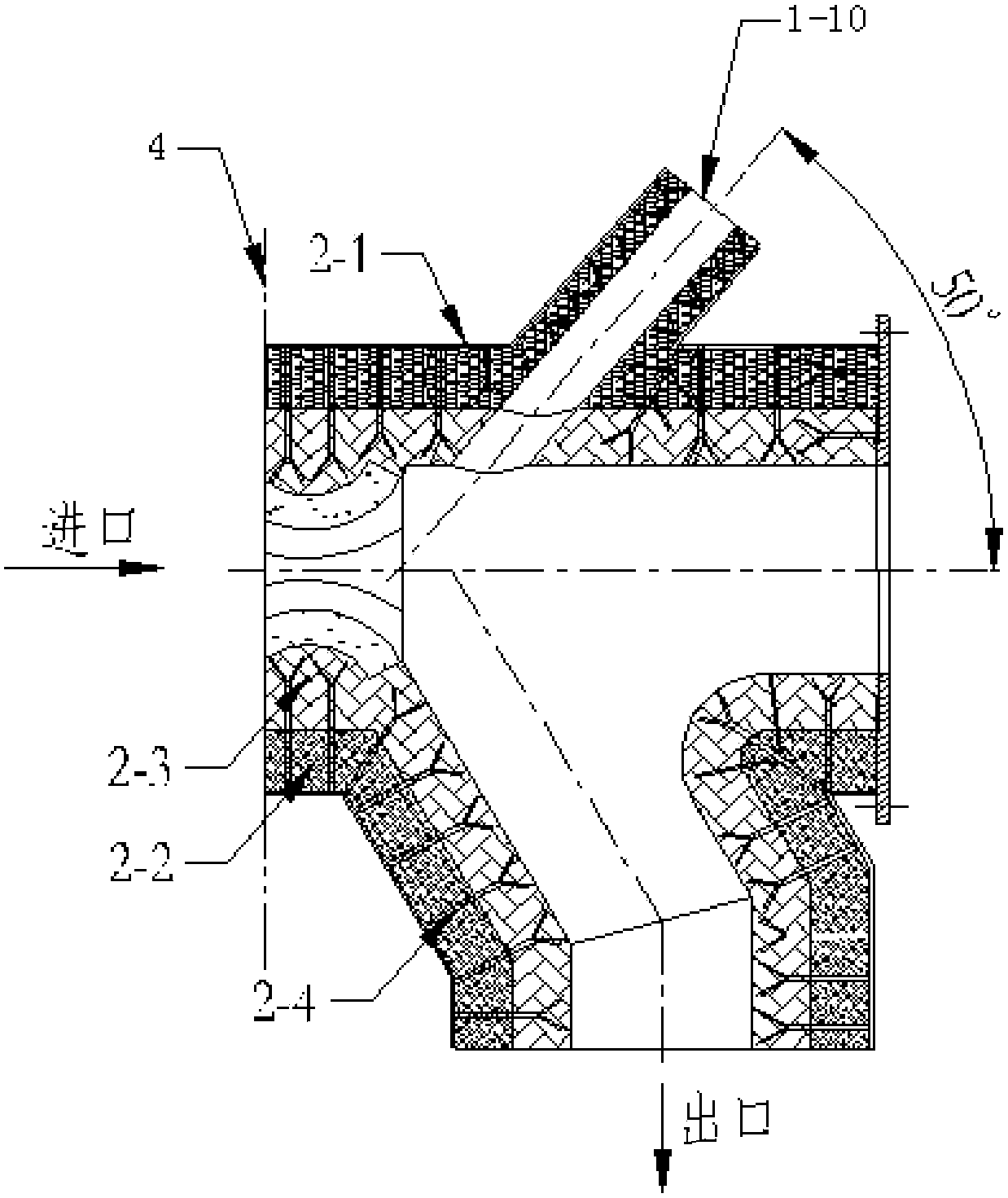

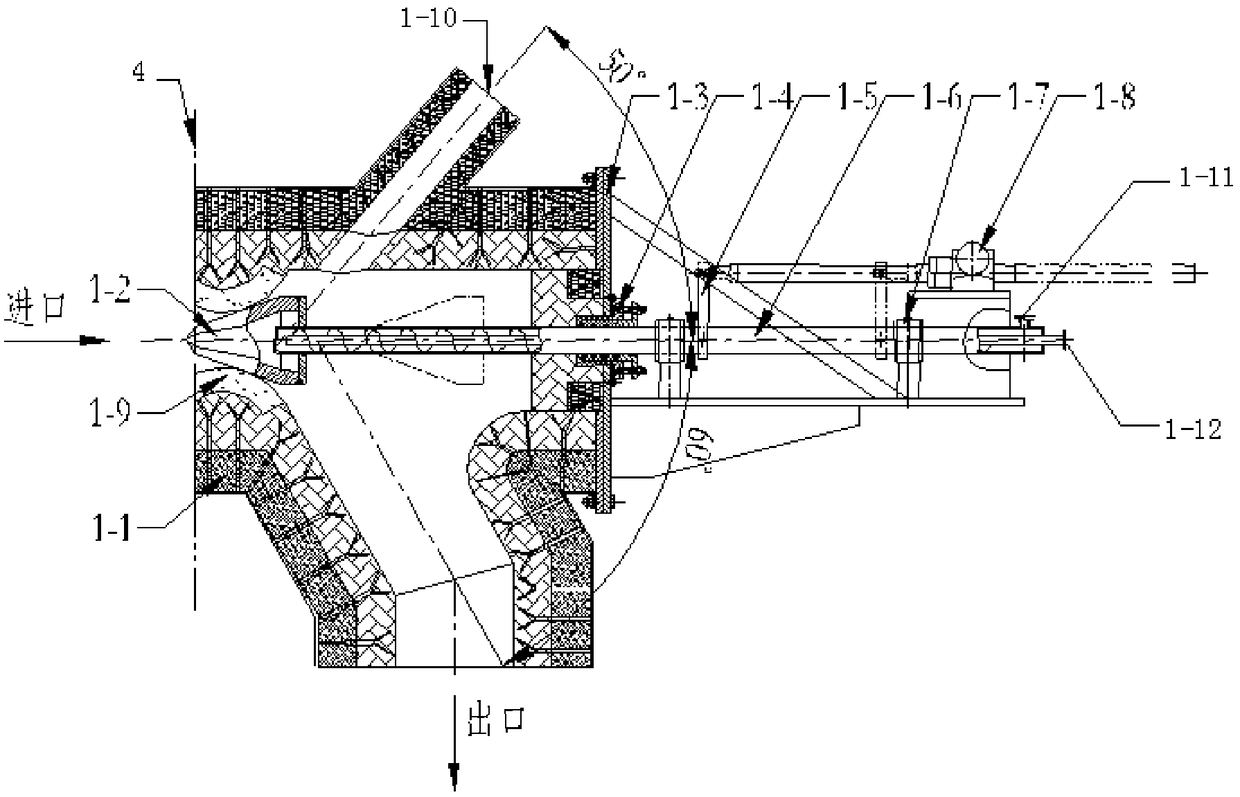

[0020] Such as Figure 1-3 As shown, the ash valve provided by the present invention includes a valve head 1-2, a valve stem 1-6, a housing 1-1, a hexagonal pyramid arc valve seat 1-9 composed of high temperature and wear-resistant corundum bricks, and an actuator Fixed frame 1-3 and electric actuator 1-8 etc. The invention provides a high-temperature ash valve, which uses the movement of the electric actuator 1-8 to drag the valve head 1-2 connected to the valve rod 1-6 to make a linear reciprocating motion, so as to meet the slag discharge flow rate during the boiler operation and according to actual needs. The function of opening / closing is set by the position, and the electric actuator can also be replaced by a hydraulic drive system.

[0021] The valve head 1-2 of the present invention is made of heat-resistant and wear-resistant cast steel. The valve head is divided into two parts: the head and the cylinder. Cut structure, the cylinder of the valve head 1-2 is a hexago...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com