A Construction Method of Anchor Pipes for Large Deep Foundation Pit Support

A technology of deep foundation pit support and construction method, which is applied in the field of large-scale deep foundation pit support anchor pipe drilling construction, can solve problems such as difficult construction, achieve the effects of reducing costs, increasing construction quality, and easy design angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

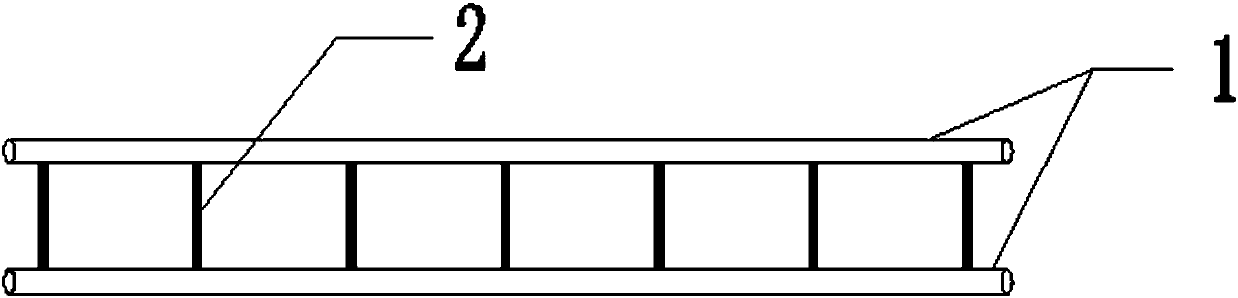

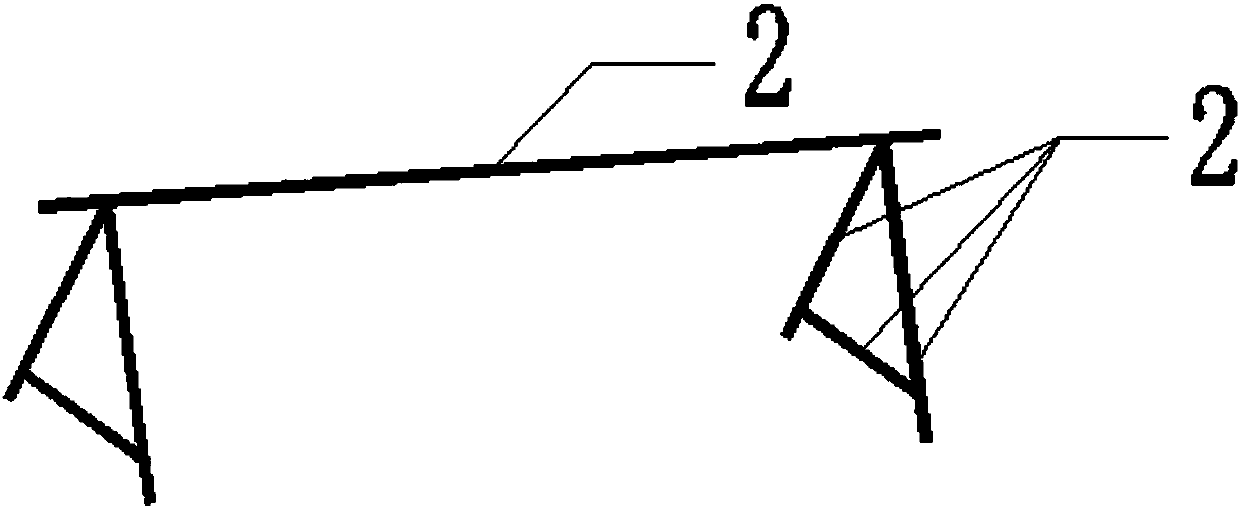

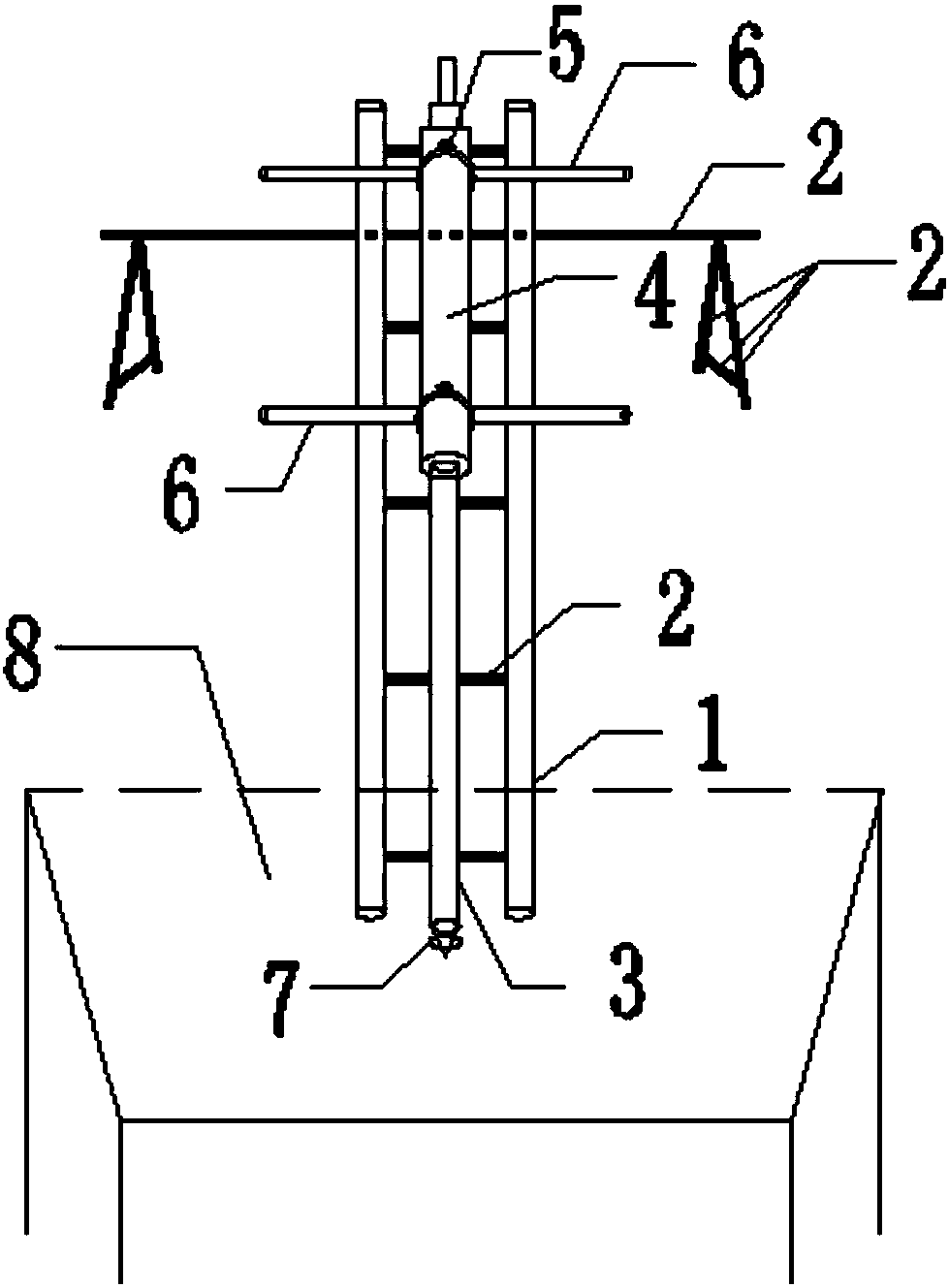

[0018] Such as Figure 1-4 As shown, the present invention discloses a large-scale deep foundation pit support anchor pipe construction method, using steel bars to weld two parallel steel pipes to fix an integral parallel bracket, and then weld a formed triangular bracket with steel bars, and weld One end of the parallel bracket is placed on the triangular support, the welding side of the parallel support steel bar is facing downward, and the other end is placed in the slope 8, the design angle of the anchor pipe 3 is adjusted, and the pneumatic impact hammer is fastened with the hoop type fixing ring 5 before and after. , the two sides of the hoop type fixing ring 5 are welded steel pipes, the steel pipe is perpendicular to the pneumatic impact hammer 4, and then the fixed pneumatic impact hammer 4 is placed in the overall steel pipe, and the front end of the processed anchor pipe 3 faces the design hole 7, and the other One end is inserted into the pneumatic impact hammer 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com