Method for controlling corrosion depth of porous silicon

A technology of etching depth and porous silicon, applied in the field of porous silicon materials, can solve the problem of not providing a method with universal applicability, and achieve the effect of saving the use of chemical reagents, reducing the impact on the environment, and shortening the research period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

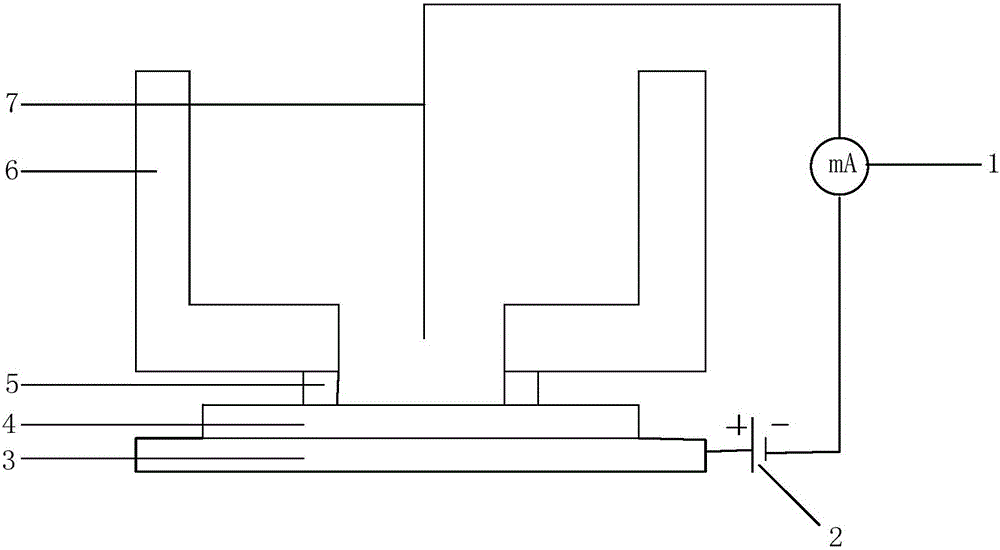

[0024] see figure 1 Place the silicon sample 4 sputtered with an aluminum film on the non-polished surface between the copper base 3 and the electrolytic cell 6, the copper base 3 is connected to the positive pole of the DC power supply 2, insert the platinum sheet 7 into the electrolyte, and connect it to the DC power supply 2 In order to ensure the tightness, there is a groove at the bottom of the electrolytic cell 6, and the rubber ring 5 is put into the groove. After pouring the electrolyte solution into the electrolytic cell 6, turn on the DC power supply 2. After 5 minutes, pour out the electrolyte solution, take out the sample, rinse it with absolute ethanol for 5 times, put it in a vacuum oven, and bake it at a low temperature of 80°C for 12 hours , and finally prepare the sample, observe the cross-section of the porous silicon by SEM and analyze it by EDX, so as to obtain the thickness of the porous silicon.

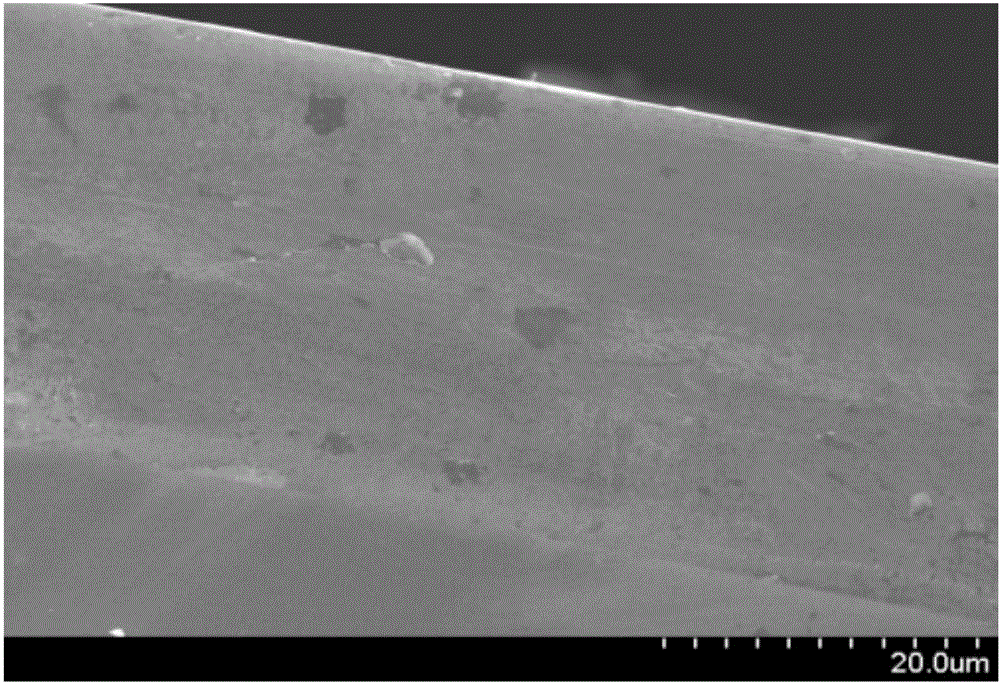

[0025] In this embodiment, the SEM images of the cross-se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com