Preparation of PEI-grafted gelatin sponge and application of PEI-grafted gelatin sponge in heavy metal sewage treatment

A technology of gelatin sponge and heavy metals, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of limited adsorption capacity of gelatin sponge, reduction of active groups, unfavorable heavy metal adsorption treatment, etc. problems, to achieve the effect of prolonging the adsorption exchange time, low preparation cost and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

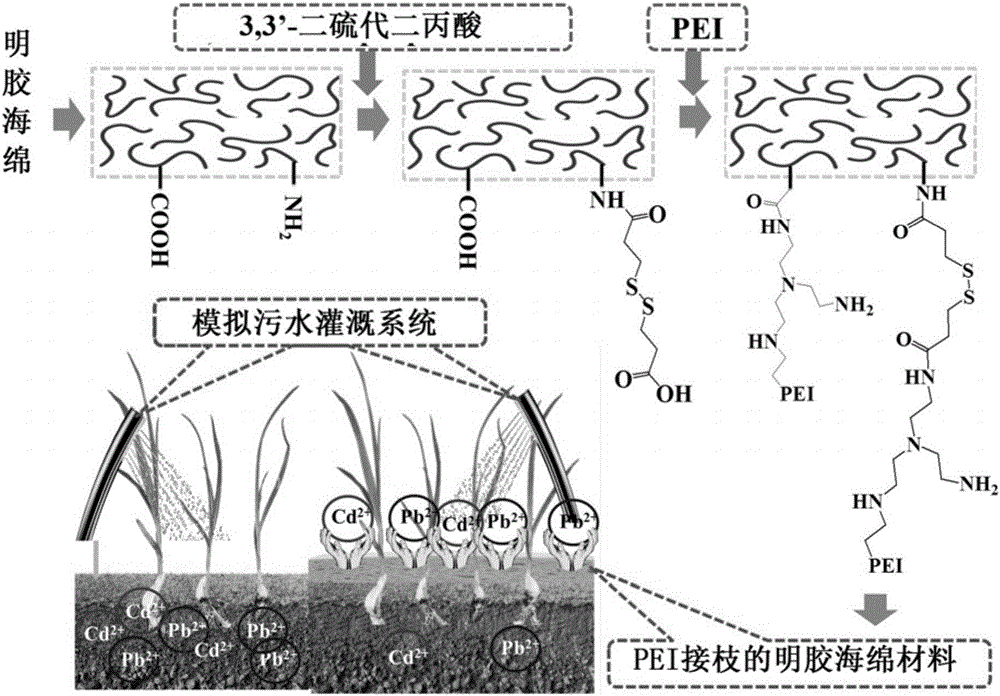

[0038] (1) Preparation of carboxylated gelatin sponge

[0039] 2 mmol of 3,3'-dithiodipropionic acid was dissolved in 8 mL of N,N-dimethylformamide, followed by 2 mmol of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide ( EDC) was dissolved in 1 mL of water, and the above two solutions were mixed and shaken at 60 °C for 1 h. Then the mixed solution was slowly added dropwise to 10 mL of water with a pH of 5, and a piece of gelatin sponge with a mass of 20 mg was added to drive away the air bubbles in the sponge, and the reaction was shaken in a shaker at 60°C for 24 hours. Finally, the reacted gelatin sponge was taken out with tweezers, washed twice with water, placed on filter paper to absorb excess water, and carboxylated modified gelatin sponge was obtained.

[0040] (2) Preparation of PEI-grafted gelatin sponge

[0041]Dissolve 1mmol PEI in 20mL water, then add 1mmol 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) and 1mmol N-hydroxysuccinimide (NHS) respectively, and mi...

Embodiment 2

[0044] (1) Preparation of carboxylated gelatin sponge

[0045] Dissolve 1 mmol of 3,3'-dithiodipropionic acid in 5 mL of N,N-dimethylformamide, followed by 1 mmol of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide ( EDC) was dissolved in 1 mL of water, and the above two solutions were mixed and shaken at 40 °C for 1 h. Then the mixed solution was slowly added dropwise to 10 mL of water with a pH of 5, and a piece of gelatin sponge with a mass of 20 mg was added to drive away the air bubbles in the sponge, and the reaction was shaken in a shaker at 40°C for 24 hours. Finally, the reacted gelatin sponge was taken out with tweezers, rinsed twice with water, placed on filter paper to absorb excess water, and carboxylated modified gelatin sponge was obtained.

[0046] (2) Preparation of PEI-grafted gelatin sponge

[0047] Dissolve 0.5 mmol PEI in 20 mL water, then add 0.5 mmol 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) and 0.5 mmol N-hydroxysuccinimide (NHS), respectively,...

Embodiment 3

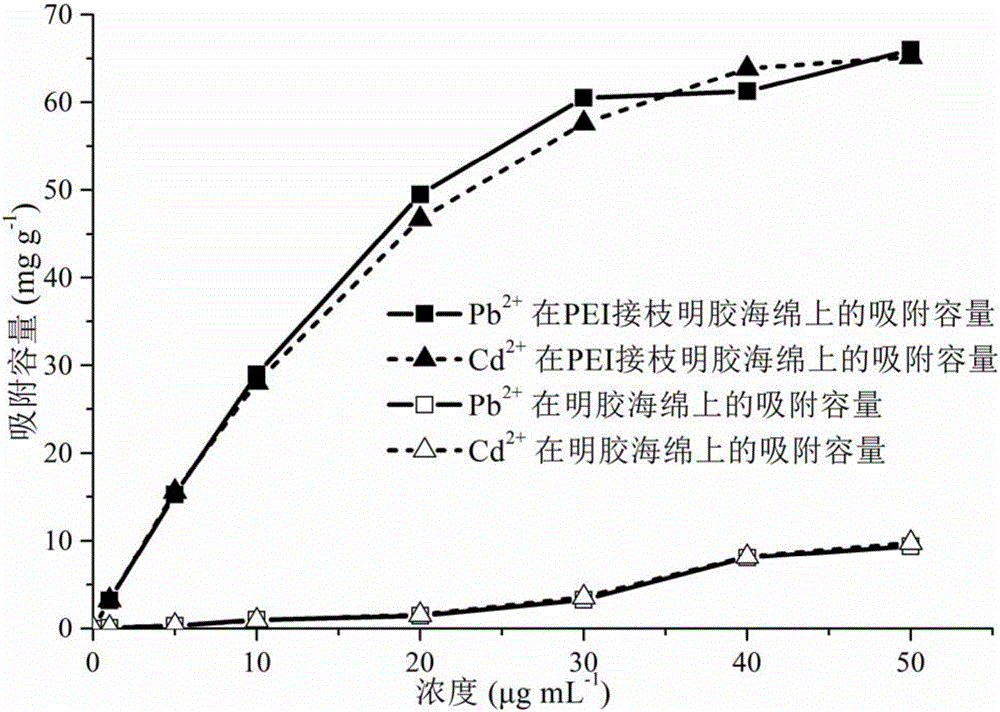

[0049] 20 mg of gelatin sponge and PEI-grafted gelatin sponge prepared in Example 2 were added to 20 mL of waste water containing lead and cadmium, respectively, and the concentrations of lead and cadmium were respectively 0-50 μg / mL. After shaking for 2 hours, use the national standard method to measure the content of lead and cadmium in the wastewater, and then calculate the adsorption capacity of the gelatin sponge material. The result is as image 3 As shown, the adsorption capacities of gelatin sponge to Pb(Ⅱ) and Cd(Ⅱ) were 9.35mg / g and 9.75mg / g respectively; while the adsorption capacities of PEI-grafted gelatin sponge to Pb(Ⅱ) and Cd(Ⅱ) were respectively 66.1 mg / g and 65.2 mg / g. The above results show that the gelatin sponge modified by PEI surface grafting greatly increases the number of amino groups on the surface of the gelatin sponge, and exhibits excellent adsorption effect on heavy metals. Therefore, the method of the present invention can be used to prepare PE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com