Method and system for preparing phosphoric acid

A technology of phosphoric acid and phosphate rock, which is applied in the direction of phosphoric acid, phosphorus oxyacids, chemical instruments and methods, etc. It can solve the problems of affecting material reduction, long roasting time, affecting heat transfer efficiency and air permeability, etc., and achieves the goal of improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

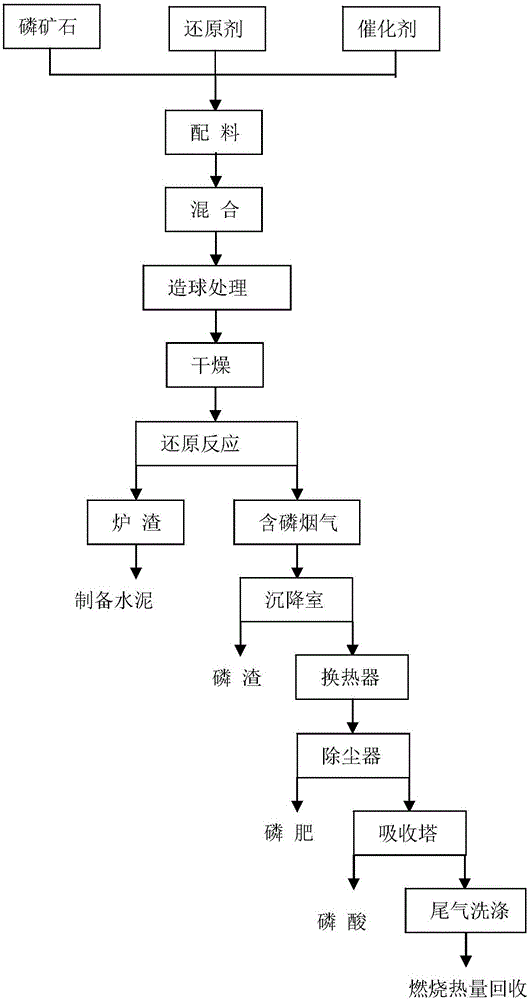

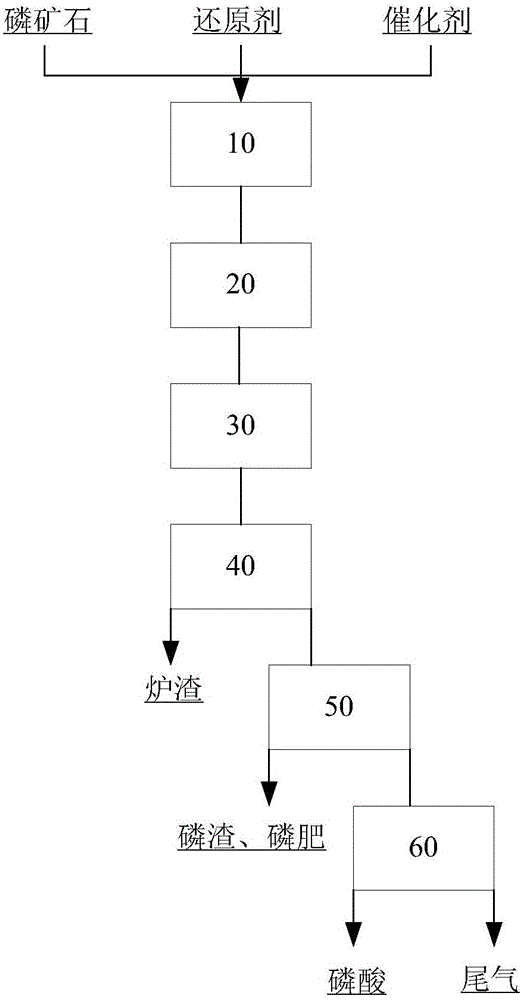

[0054] In order to facilitate the description of the system for preparing phosphoric acid in specific embodiments of the present invention, the specific implementation method of the system will be described below.

[0055] According to a specific embodiment of the present invention, firstly, the phosphate rock, the reducing agent and the catalyst are mixed in the mixing device 10 to obtain a mixed material. According to a specific embodiment of the present invention, the mass ratio of the above-mentioned raw materials, namely phosphate rock, reducing agent and catalyst, is not particularly limited, and according to a specific embodiment of the present invention, its mass ratio can be 100:(15-20):(1 -2). In this way, the reducing agent and catalyst added in this mass range can achieve sufficient reduction of phosphate rock, and waste of resources can be avoided. According to a specific embodiment of the present invention, the above mass ratio is unexpectedly obtained by the in...

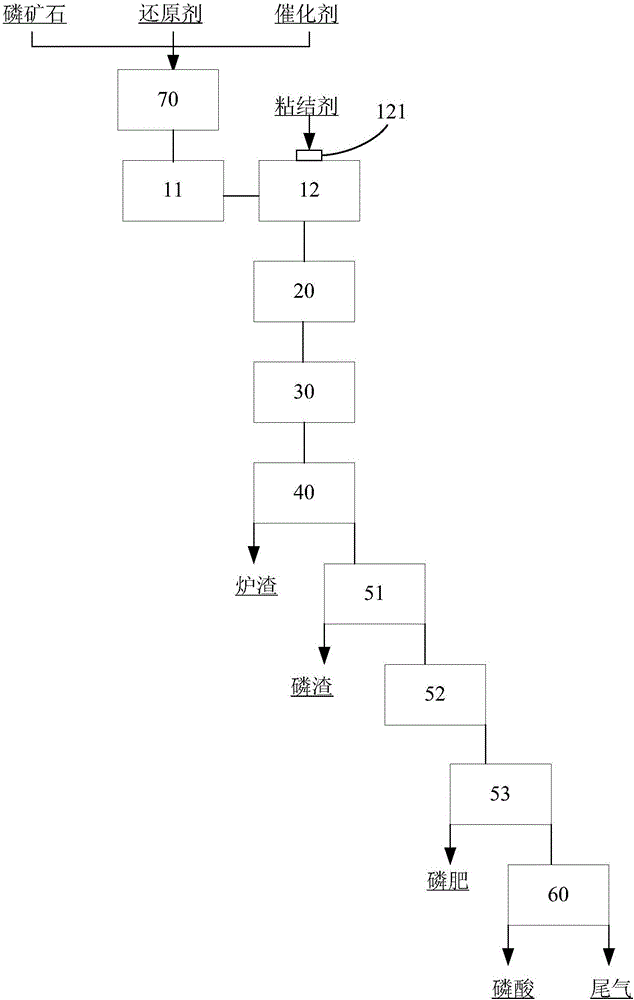

Embodiment 1

[0080] The raw ore composition of a phosphate rock in Yunnan is P 2 o 5 24.78%, CaO 38.98%, SiO 2 Accounting for 13.56%, Al 2 o 3 Accounted for 1.68%, F accounted for 2.23%, anthracite contains 78.92% of fixed carbon, raw material batching conditions are phosphate rock: anthracite: catalyst = 100:18:1.5 (mass fraction), the above materials are added to the mixture during the mixing process of the mixer 3% of the weight of molasses, add an appropriate amount of water, adjust the water content of the mixture to 7%, press the balls through a high-pressure double-roller ball press, and the pressed pellets are ellipsoids with a length of 30mm, a width of 20mm, and a thickness of about 15mm. Enter the chain grate dryer for drying at 240°C. The dried pellets contain less than 2% water. After being screened by the belt, they are sent to the regenerative rotary hearth furnace for reduction. The air-fuel ratio in the rotary hearth furnace is controlled at 9.5 , the temperature of th...

Embodiment 2

[0082] A phosphate mine P in Ningxia2 o 5 Accounting for 35%, the fixed carbon content of anthracite is 77.86%, the raw material ingredients are phosphate ore: anthracite: catalyst = 100:20:2 (mass fraction), the above materials are mixed evenly and added to a pelletizing disc with a diameter of 6 meters for disc For pelletizing, the binder used for pelletizing is bentonite, accounting for 1% of the mixture, the water content of the pellets is controlled at 8%-10%, the diameter of the pellets is 8-12mm, and the carbon-containing pellets are placed into The chain grate dryer is used for drying, the drying temperature is about 240°C, the dried pellets contain less than 2% water, and then sent to the regenerative rotary hearth furnace for reduction. The air-fuel ratio in the rotary hearth furnace is controlled at 9, pre- The temperature of the hot section is 900°C, the preheating time is 5 minutes, the temperature of the reduction section is 1080°C, the reduction time is 32 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com