A device and method for processing belt red coke

A red coke and belt technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of increased water content of surrounding coke, damage to the subsequent belt system, unfavorable blast furnace production, etc., to achieve reasonable structure and avoid Increased water content of coke and the effect of ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

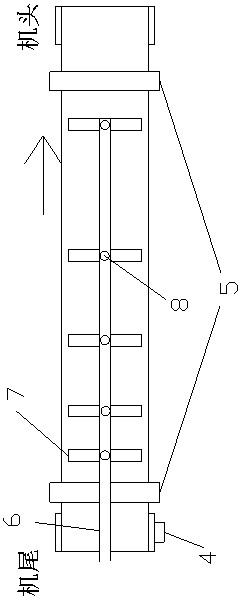

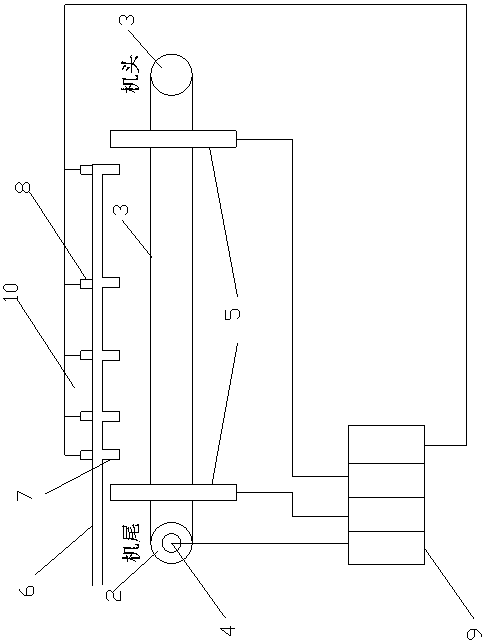

[0020] Embodiment 1: see figure 1 , figure 2 , a device for processing belt red coke, said device comprising a belt machine head 1, a belt machine tail 2, a belt 3 arranged between the belt machine head 1 and the belt machine tail 2, said device comprising a red coke detection device 5, Red coke tracking device 4, red coke extinguishing device 10 and red coke processing control system 9, red coke processing control system 9 is electrically connected with red coke detection device 5, red coke tracking device 4 and red coke extinguishing device 10, the belt A red-focus detection device 5 is arranged on the machine head 1 and the belt machine tail 2, and a red-focus tracking device 4 is arranged on the belt tail. The position of the coke, and then control the extinguishing device to extinguish the red coke. In this technical solution, the red coke detection device is used to confirm whether there is red coke on the belt. Since the temperature of the red coke is higher than th...

Embodiment 2

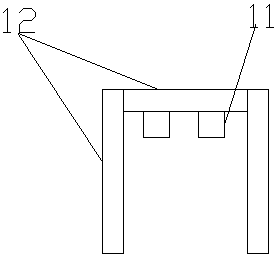

[0021] Example 2: see image 3 , as an improvement of the present invention, the red focus detection device includes an infrared temperature measuring element 11 and an infrared temperature measuring system bracket 12, and the infrared temperature measuring element is set as an infrared temperature measuring sensor.

Embodiment 3

[0022] Embodiment 3: see figure 2 , Figure 4 , Figure 5 , as an improvement of the present invention, the red coke extinguishing device includes a water pipe 6, a coke extinguishing nozzle 7 arranged on the water pipe 6, and a water spray solenoid valve 8 controlling the coke extinguishing nozzle, and the whole red coke extinguishing device 10 is arranged on Above belt 3. The red coke extinguishing device is installed on the upper part of the belt. It is composed of water spray solenoid valves controlled by several rows of solenoid valves, water pipes 6 and quenching nozzles 7. It is used to continuously and accurately extinguish the red coke existing on the belt. The running direction is arranged in the order of dense first and sparse later, which is convenient for rapid cooling of red coke at high temperature and gradual cooling after cooling down, ensuring full coke quenching and avoiding excessive water entering into coke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com