Novel low-frequency inertial vibration feeding machine

A vibrating feeder and inertial technology, which is applied to vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of unsatisfactory industrial production material transportation, large basic force, small processing capacity, etc., and increase equipment mobility High efficiency, pure output, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

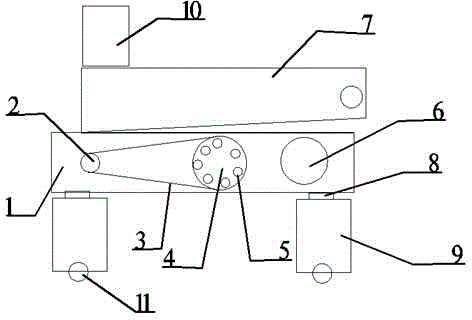

[0019] A new low-frequency inertial vibrating feeder is characterized in that it includes: a frame 1, a driving pulley 2, a V-belt 3, a driven pulley 4, a low-frequency inertial vibration exciter 5, an elastic connection system 6, and a feeding trough 7, Rubber shock-absorbing spring 8, base 9; frame 1 four corners are equipped with rubber shock-absorbing spring 8, and base 9 is connected, and feed trough body 7 is installed on frame 1 by support, rectangular cut rubber spring, and frame 1 The built-in single-axis inertial vibrator 5 is driven to rotate by the driven pulley 4, and the driving pulley 2 and the driven pulley 4 are connected through the V-belt 3; when in use: the vibration source of the tank vibrating feed is a low-frequency inertial vibrator The vibrator is composed of two eccentric shafts and a gear pair. The motor drives the driving shaft through the V-belt, and then the gear on the driving shaft meshes with the driven shaft to rotate. The material flows conti...

Embodiment 2

[0021] Example 2 as figure 1 As shown, it is improved on the basis of Embodiment 1. Its frame 1 is horizontally provided with motor, support, low-frequency inertial vibrator 5, and the motor drives the low-frequency inertia The vibrator 5 rotates. The structure is more compact, the transmission efficiency is higher, the transmission ratio is improved, and the cost is saved.

Embodiment 3

[0023] Example 3 as figure 1 Shown, it is improved on the basis of embodiment 1, and its described feeding trough body 7 is provided with negative pressure dedusting device 10, and this negative pressure dedusting device 10 is film-coated flat dedusting bag type. The use of dust removal equipment for dust removal ensures a clean and hygienic use environment. At the same time, the use of bag dust collectors is conducive to the reuse of accumulated dust and saves costs. At the same time, the film-coated dust bag is used to increase the use time of the dust bag, which can be used for a longer time at one time, reduces the time for replacing the dust bag, and increases work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com